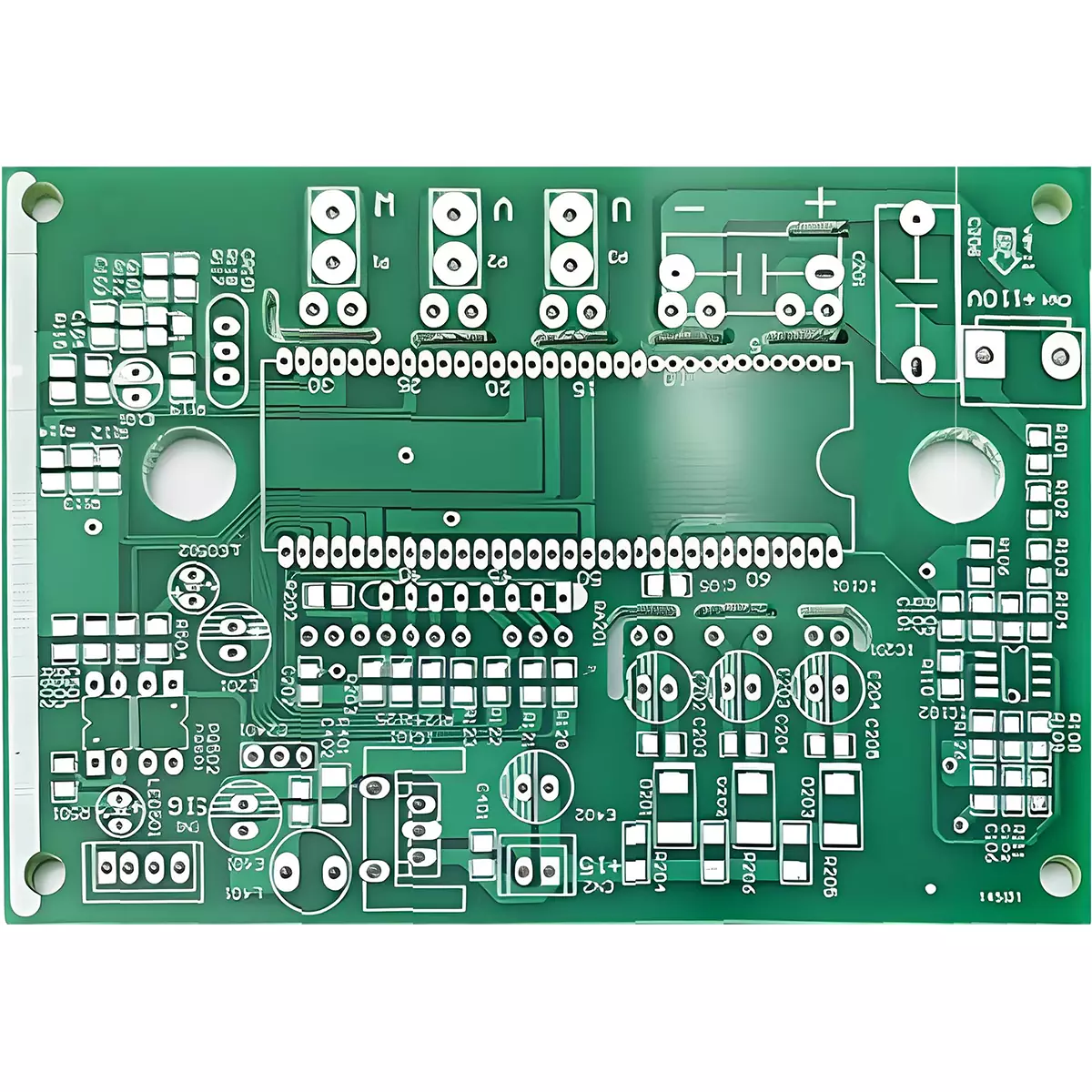

Product Name: Double Sided PCB

Material: KB FR-4

Layers: 2 layers PCB

Thickness: 1.6mm

Copper thickness: 1oz

Surface technology: Lead-free HASL

Solder mask: Green

Silk screen : white

Minimum line width/spacing: 0.2/0.2mm

Minimum through-hole: 0.3mm

Application: Power supply, various electronic products

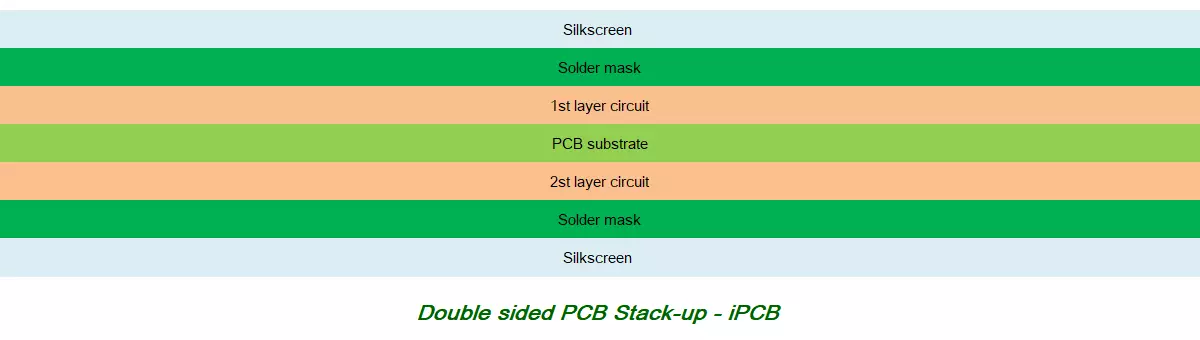

What is double sided PCB?

Double sided PCB is a type of circuit board that is covered with circuits on both sides. Compared with single layer PCB board, double sided board can accommodate more circuit components in the same board size, thus enabling more complex circuit designs. Double sided PCB usually use double sided wiring, which allows circuits to be connected on both sides by passing through holes between the two sides. This method greatly improves the density and reliability of the circuit board.

Double sided PCB is a common type of circuit board with high reliability and flexibility. Double sided PCB are suitable for various application scenarios that require complex circuit layouts and high-density assembly. It is commonly found in fields such as computers, communication equipment, industrial control, and consumer electronics.

Double sided PCB production process

PCB cutting and edge grinding -> drilling -> copper sinking -> electroplated copper thickening -> outer layer graphics -> tin plating, etching and tin removal -> secondary drilling -> inspection -> silk screen solder mask -> gold-plated plug -> hot air leveling -> silk screen characters -> shape processing -> testing -> inspection.

Drilling: Due to the need to attach components on both sides of a double sided PCB, there needs to be a way to connect the circuits on one side of the circuit board to the other. This is achieved by drilling small holes or through holes on the circuit board. There are various techniques related to PCB drilling, but the technique used for double sided PCB is called Plating Through Hole (PTH)

Copper deposition and electroplating: Coating the entire hole wall with metal to achieve electrical interconnection between the inner and outer layers of the circuit board

Screen: using specialized printing materials to print circuit graphics, solder mask graphics, and character marking graphics on the copper-clad board of a circuit board

Surface treatment process: as a corrosion-resistant protective layer during etching and a solderable coating on the finished board

Etching circuit: In order to achieve the desired circuit path and eliminate excess copper, the circuit board needs to go through a so-called etching solution. This solution will remove excess copper from the circuit board

Testing method: High quality PCB manufacturers prioritize quality in the production process of circuit board. High quality PCB circuit board have strict requirements for appearance and internal circuits. Common PCB inspections include AOI testing, X-ray testing, online testing (flying needle testing, needle bed testing), etc.

Advantages of double sided PCB

High flexibility: Due to having two sides, double sided board can accommodate more circuit components in the same board size. This makes it very suitable for circuit designs that require high integration.

Higher reliability: By threading the circuit through holes between both sides, the circuit can be connected on both sides, greatly improving the density and reliability of the circuit board.

More complex design: Compared to single layer PCB, double sided board can achieve more complex circuit designs. Double sided wiring makes circuit design more flexible, while also improving the performance and stability of circuit board.

What is the difference between single layer PCB and double layer PCB?

The difference between single layer PCB and double layer PCB is that the circuit of a single layer PCB board is only on one side of the PCB board, while the circuit of a double sided PCB board can be connected to the circuit of the double sided PCB board through a through-hole in the middle between the two sides of the PCB board. In addition to the different production processes, double layer PCB and single layer PCB also have an additional copper deposition process, which is the process of conducting double sided circuits.

1. Single sided printed circuit board are usually made of single-sided copper-clad laminates, and etched circuit patterns are created on the copper surface using screen printing or photoimaging methods. Excess copper foil is removed by chemical etching to form conductor patterns.

2. A double sided printed circuit board has two layers of conductor patterns, with the upper and lower conductive holes connected by through holes. In the processing of printed circuit board, copper layers are plated on the walls of the holes with expensive perforations to make the upper and lower layers conductive. Double sided printed circuit board usually use double sided copper foil laminates, and corrosion-resistant circuit patterns are made on the copper surface using screen printing or photoimaging methods. Excess copper foil is removed by chemical etching to form conductor patterns.

3. Double layer PCB and single layer PCB can be basically distinguished from the appearance. Single layer PCB is a circuit board with only one layer and wire layers, while Double sided PCB has two wiring layers with conductive holes in the middle, so this is the difference between single and double sided circuit board.

Double sided PCB

Precautions for double layer PCB manufacturing

The important part of PCB engineer's work is PCB design. For designers, being able to process their own design drawings and successfully use them can be quite fulfilling. PCB design is more complex than other product designs, and a small detail error can directly result in the entire PCB board being scrapped. Once the design is completed, PCB processing is particularly important. How to accurately process the PCB design? What should be paid attention to in PCB processing?

1. PCB factory scale: The daily production capacity of the PCB factory, as well as whether there is any experience of cooperating with large brands.

2. Whether the PCB equipment is advanced: Whether the PCB factory has stable production equipment from well-known brands directly affects the quality of the PCB board.

3. Whether the process meets the design requirements: It can meet its own process requirements, such as immersion gold process, lead spray tin, etc., to ensure the quality of the PCB board.

4. Whether the service is in place: In addition to product quality, service quality is also an important factor in inspecting PCB factories. PCB factories with complete after-sales systems and strong after-sales support should be selected as much as possible.

After determining the PCB factory for cooperation, submit the corresponding PCB processing files to the factory as soon as possible, such as gerber files.

After receiving a double layer PCB order, the first step for iPCB is to check the PCB gerber files to avoid a series of subsequent processing problems caused by initial PCB file issues. After confirming the accuracy, conduct comprehensive approval of the double layer PCB process and configure the process with our own double layer PCB factory. In addition to ensuring the quality of the PCB board, iPCB also pays attention to delivery time. At present, iPCB customers have increasingly high requirements for delivery time, and some double sided PCB users require PCB sample manufacturing to be completed within 24 hours.

Product Name: Double Sided PCB

Material: KB FR-4

Layers: 2 layers PCB

Thickness: 1.6mm

Copper thickness: 1oz

Surface technology: Lead-free HASL

Solder mask: Green

Silk screen : white

Minimum line width/spacing: 0.2/0.2mm

Minimum through-hole: 0.3mm

Application: Power supply, various electronic products

iPCB Corporation provides support for PCB Prototype and Electronic Manufacturing. You can request consultation or quotation for PCB, PCBA and ODM here, please contact email: sales@ipcb.com

We will respond very quickly.