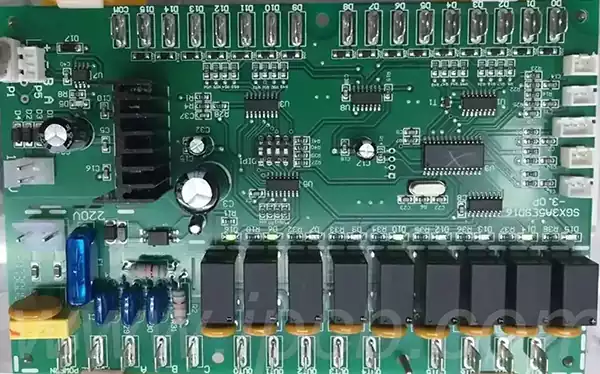

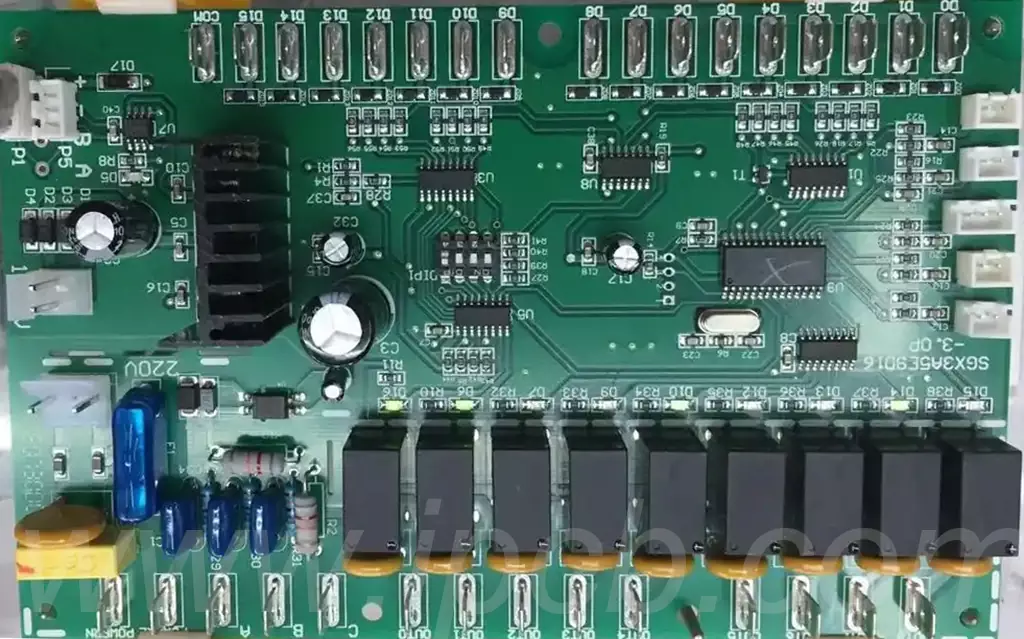

Product Name:Air Conditioner PCB

Material:FR-4、CEM-1、aluminium substrate

Thickness:1.6mm

Copper thickness:1.4OZ/1oz

Surface technology:Glod

Solder mask:Green,Black

Silk screen:White

Minimum line width/spacing:6/6mil

Minimum through-hole:0.3mm

Application: Domestic and commercial central air-conditioning, chiller and other large-scale equipment

The air conditioner pcb,as a core component of the air-conditioning system, bears the heavy responsibility of regulating air-conditioning operation and temperature management. It consists of a network of electronic components and circuits, including sensors, microprocessors, electromagnetic relays and other components.

The air conditioner circuit board operates according to the control strategy of the air-conditioning system. Once the user has set the desired temperature value for the air conditioner, the circuit board then uses sensors to monitor the current indoor temperature conditions and directs the start-up and adjustment of the cooling or heating system according to the difference between the measured temperature and the target temperature, so as to accurately control the indoor temperature.

1.Power supply access process:AC power is introduced into the circuit board, and after a series of rectification and filtering steps, it is converted into a stable DC power supply.

2.Microcontroller Startup Configuration:In the early stage of power-on, the microcontroller performs initialisation steps, including clock setting, pin configuration and other initialisation operations.

3.Sensor Data Acquisition:Through specific pin connections,the sensor captures information such as temperature and pressure in the environment and converts these physical quantities into recognisable digital signals.

4.Control Logic Implementation:Based on the data fed back from the sensors and the user's preset parameters, the microcontroller generates the corresponding control instructions in accordance with the established control strategy.

5.Power amplification drive: control instructions are amplified by a special drive circuit to drive the compressor, fan and other key components of the start and run.

6.Communication and interaction function: the circuit board establishes contact with external remote control or other devices through the communication interface, supporting remote command reception and data exchange.

Types of core circuit boards in air conditioning units

Control Circuit Board

The control circuit board plays a pivotal role in the air conditioner main unit and it is the centre that controls the working mode of the air conditioner. This circuit board is mainly responsible for receiving signals sent by the indoor unit, remote control, etc. and controlling the working modes of the compressor, fan, solenoid valve, and other components through the circuit, so as to achieve the cooling or heating effect of the air conditioner.

The core components of the control circuit board include microprocessor, capacitor, resistor, transistor, relay and voltage regulator. Among them, the microprocessor is the brain of the control circuit board, known for its high-speed computing, compact size, low power consumption and programmability. Components such as capacitors, resistors, transistors, and relays are responsible for signal processing, transmission, and control, while the voltage regulator ensures that the board receives a stable supply of power.

Power Control Circuit Board

The power control circuit board is another key circuit board in the air conditioner mainframe, and its main responsibility is to adjust the current of various devices in the air conditioning system, such as compressors, fans, solenoid valves, etc. During the operation of the air conditioner, this circuit board is used to adjust the current of the air conditioning system. During the operation of the air conditioner, the board needs to handle a large amount of power input and output, so it must have a high current-carrying capacity and anti-interference performance.

The main components of the power control circuit board include thyristors, triggers, transistors, capacitors, resistors, and so on. Thyristor is the core component of the power control circuit board, which can realise the switching control of the circuit and the regulation of the current. Triggers, transistors and other components are responsible for controlling the switching of the thyristor, thus realising the regulation of the current of the relevant equipment. Capacitors, resistors and other components are responsible for reducing the interference in the circuit to ensure the stable operation of the circuit.

air conditioner pcb

Components

Air conditioner pcb consists of several electronic components and circuits connected together. The following are the common components

Sensor:Air conditioner pcb is usually equipped with a temperature sensor to detect the room temperature. The sensor converts the temperature signal into an electrical signal for processing by the circuit board.

Microcontroller:The microcontroller is the core component of the air conditioner pcb and is responsible for controlling and regulating the operation of the air conditioning system. It receives the signals from the sensors and determines whether cooling or heating is required according to the set algorithm and logic, and controls the switching on and off of the cooling unit or heater.

Relay:A relay is a switching device on a circuit board that controls the operation of a refrigeration unit or heater. The microcontroller controls the opening and closing of the relay to start and stop the cooling or heating unit.

Capacitors and Resistors:Capacitors are used to store electrical energy and provide a steady current, while resistors are used to limit the flow of current.

Circuit Connections:The components in an air conditioner pcb are connected together through circuits to form a complete circuit system. Circuit connections are usually realised using materials such as wires and printed circuit boards.

Air conditioner pcb relys on insulating materials to ensure the stable operation of their circuits, these materials are mainly FR4, CEM-1 and aluminium substrates, etc.FR4 is a kind of glass-fibre-reinforced epoxy resin sheet,with excellent heat resistance,mechanical strength and electrical insulation properties, is a commonly used material in the manufacture of circuit boards for electronic products. CEM-1,on the other hand,is a paper-based phenolic resin board with good insulating properties and ease of processing, which is suitable for the manufacturing needs of most electronic products.As a metal-based circuit board, aluminium substrates are particularly suitable for air-conditioning equipment that requires efficient heat dissipation due to their excellent heat dissipation properties.

In addition to insulating materials,conductive materials are also a key component of air conditioner circuit boards.Copper foil,as a widely used conductive material, occupies an important position in circuit board manufacturing due to its excellent conductivity and easy processing.Silver paste, on the other hand,is the preferred material for high-precision conductive connections due to its extremely high conductivity.

Role of the air conditioner pcb:

Control function: the circuit board is the control centre of the air conditioning system. It receives signals from the remote control and controls the operating status of the air conditioner according to these signals, such as switching on and off, temperature adjustment, wind speed setting, etc. The microprocessor on the circuit board processes and sends out the corresponding control signals according to the received instructions to ensure that the air conditioner operates according to the user's needs.

Power management: the circuit board is also responsible for the power management of the air conditioner. It connects the power input of the air conditioner and the power output of each component to ensure stable transmission of current. In the event of power instability, the circuit board is also equipped with protection measures to prevent the equipment from being damaged by too much or too little current.

Works with sensors: the air conditioner pcb works in tandem with the sensors inside.The sensors are responsible for monitoring changes in the indoor environmental parameters in real time and feeding this data back to the circuit board. The circuit board adjusts the working state of the air conditioner according to the received data and the preset thresholds to maintain the comfort and energy saving of the indoor environment.

Fault detection and protection: the circuit board has a fault detection function.When the air conditioning system malfunctions, the circuit board can automatically detect and identify the type and location of the malfunction and take appropriate measures to repair or turn off the air conditioner to avoid further damage.At the same time,the circuit board can also provide fault codes to facilitate the maintenance personnel to quickly locate and solve the problem.

Meaning of the letter markings on the air conditioner pcb:

1.R: symbolises the compressor.When the air conditioner enters the cooling mode,the circuit board will activate the compressor through the R command, prompting the refrigerant to circulate in the system, thus lowering the indoor temperature.

2.Y: represents the air supply motor.When the air conditioner needs to perform the function of air supply,the circuit board will activate the air supply motor according to the Y instruction to drive the air flow and achieve the ventilation effect.

3.G: also represents the air supply device,specifically the fan. When the air conditioner needs to supply air,the G instruction will be issued by the circuit board to control the fan rotation and promote air circulation.

4.C: represents the negative power connection point,the C terminal is one of the power access points of the whole circuit board, responsible for providing stable negative power.

5.W: represents the electric heating element.When the air conditioner needs to make heat, the circuit board activates the electric heating device through the W command to heat the air.

6.B: stands for reverse controller.This controller is responsible for realising the switching of the air conditioner between cooling and heating modes.

7.O: stands for four-way valve control function. The four-way valve is used to regulate the flow of refrigerant between the inside and outside units of the air conditioner. The O command is issued by the circuit board to control the action of the four-way valve.

8.E: represents the outdoor unit. The outdoor unit is connected to the circuit board through the communication line identified by E, and is responsible for transmitting control commands, sensor information and communication.

9.F: Indoor unit. The indoor unit is also connected to the circuit board through the communication line identified by F, and is responsible for transmitting control commands, sensor signals and communication.

As the core component of the air-conditioning system, the air conditioner pcb achieves precise control of air-conditioning operation and temperature regulation by integrating sensors, microcontrollers, relays and other components. Its stable power management, co-operative work with sensors and fault detection function guarantee the normal operation of the air-conditioning system and the user's comfortable experience.

Product Name:Air Conditioner PCB

Material:FR-4、CEM-1、aluminium substrate

Thickness:1.6mm

Copper thickness:1.4OZ/1oz

Surface technology:Glod

Solder mask:Green,Black

Silk screen:White

Minimum line width/spacing:6/6mil

Minimum through-hole:0.3mm

Application: Domestic and commercial central air-conditioning, chiller and other large-scale equipment

iPCB Corporation provides support for PCB Prototype and Electronic Manufacturing. You can request consultation or quotation for PCB, PCBA and ODM here, please contact email: sales@ipcb.com

We will respond very quickly.