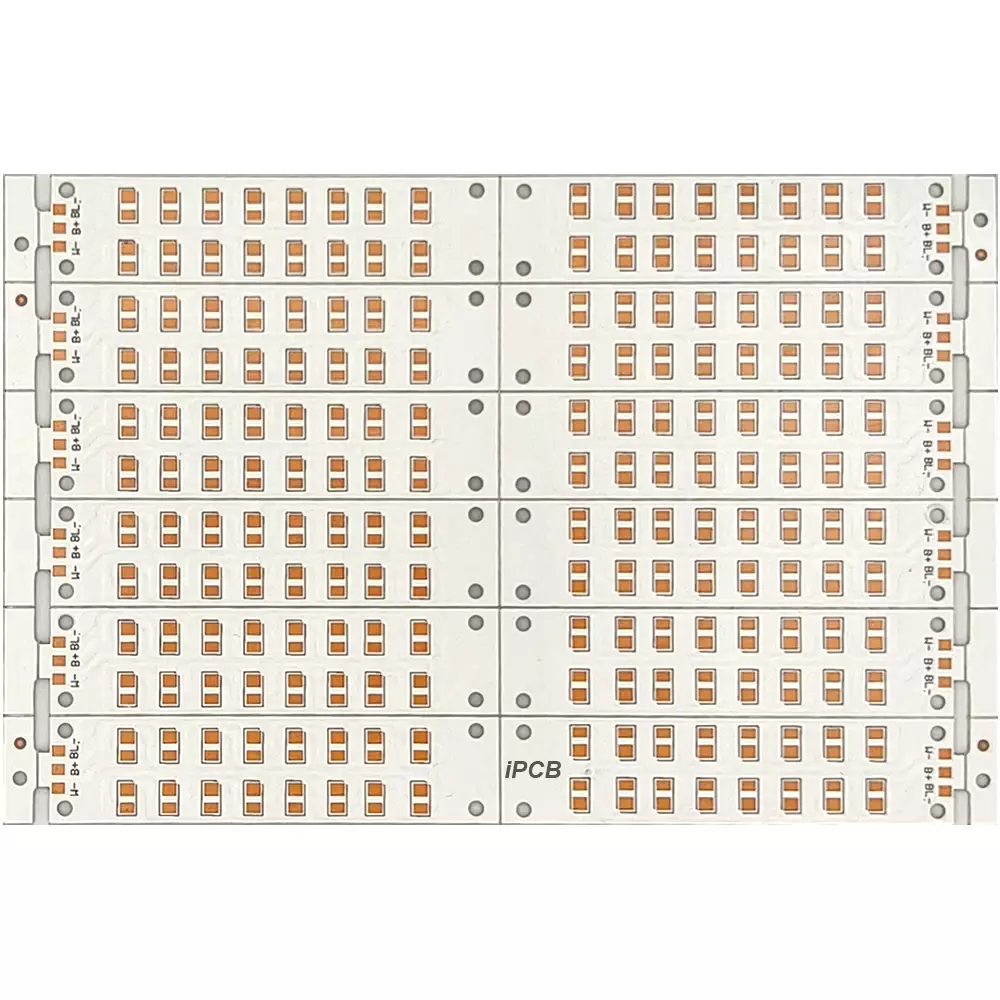

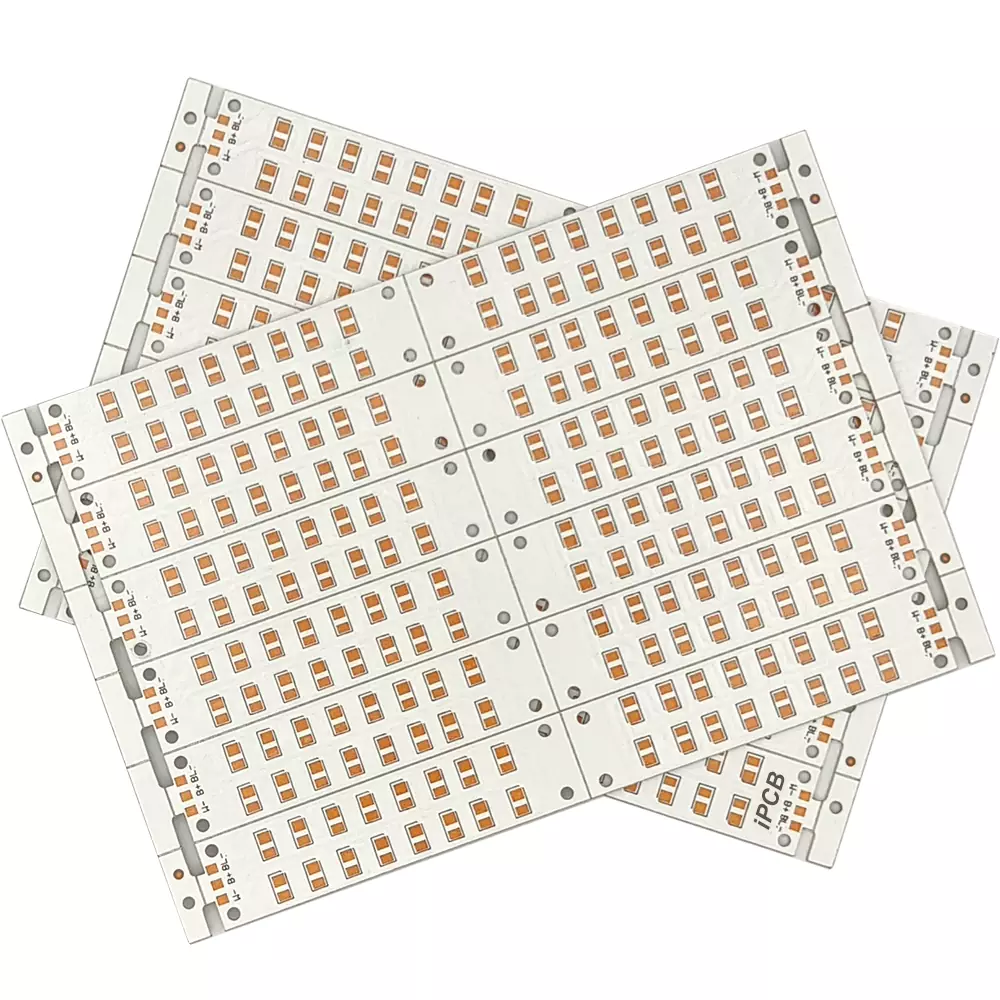

Product Name:Aluminum PCB

Material:aluminum base

Thickness: 1.0mm

Copper thickness: 1/OZ

Surface technology: Lead-Free Hasl

Solder mask: White/Black/

Silk screen: White

Minimum line width/spacing: 3mil

Minimum through-hole: 0.3mm

Application:LED lamp pcb

Aluminum PCB is a kind of PCB, which is a metal-based copper-clad plate with good heat dissipation function. It takes aluminium as the substrate, and forms one or several layers of metal copper foils on the surface through chemical plating or etching, which is a kind of commonly used metal substrate, widely used in electronics, LED and other industries. On the aluminium substrate substrate, crowned with a layer of high thermal conductivity, low resistivity metal copper foil, this copper foil and aluminium substrate contact is very good, its adhesive strength is very high, and excellent heat transfer performance.

Aluminium PCB working principle

Power devices are surface-mounted on the circuit layer, and the heat generated during device operation is quickly conducted to the metal base layer through the insulating layer, and then the metal base layer transfers the heat out to achieve heat dissipation for the device (please see Figure 2).Compared with traditional FR-4, aluminium substrate can reduce the thermal resistance to a minimum,which makes aluminium substrate has excellent thermal conductivity; compared with thick film ceramic circuits, it has extremely good mechanical properties.

Composition of aluminium pcb:

1.Line layer

The line layer (usually electrolytic copper foil) is etched to form a printed circuit for device assembly and connection. Compared with the traditional FR-4,with the same thickness and the same line width, aluminium substrate can carry higher current.

2.Insulation Layer

Insulation layer is the core technology of aluminium pcb,mainly plays the function of bonding, insulation and thermal conductivity.Aluminium PCB insulation layer is the largest thermal barrier in the power module structure. The better the thermal conductivity of the insulating layer, the more conducive to the diffusion of heat generated by the device operation, but also the more conducive to reducing the operating temperature of the device, thereby improving the power load of the module, reducing the volume, extending the life, and improve power output and other purposes.

3.Metal base

What kind of metal is used for the insulating metal substrate depends on the comprehensive consideration of the coefficient of thermal expansion, thermal conductivity, strength, hardness, weight, surface condition and cost of the metal substrate.

Classification of Aluminium PCB:

Classification according to substrate material

Pure Aluminium PCB

Pure aluminium substrates are the most popular type of aluminium substrate and consist of a pure aluminium sheet with an insulating layer. Pure aluminium substrates have excellent thermal conductivity and mechanical strength, while the insulating layer ensures the safe and secure operation of circuits.Pure aluminium pcb is widely used in a variety of electronic products, especially in those applications where high thermal performance is required.

Copper-Aluminium Hybrid Substrates

Copper-aluminium hybrid substrates are made of two metals, copper and aluminium,through a composite process.Copper is known for its excellent electrical and thermal conductivity,while aluminium is known for its lightness and corrosion resistance.Copper-aluminium hybrid substrates combine the advantages of these two metals and exhibit excellent thermal and electrical performance,making them particularly suitable for high-performance electronic products.

Stainless Steel over Aluminium PCB

Stainless steel over aluminium pcb uses stainless steel as the base material, which is covered with a layer of aluminium, and the two are tightly combined through a special process. Stainless steel clad aluminium substrate not only has high mechanical strength and excellent corrosion resistance, but also retains the original good heat dissipation properties of aluminium substrate. This type of substrate is very suitable for electronic equipment operating in harsh environments.

According to the production process classification

Copper Plated Aluminium PCB

Copper clad aluminium pcb is substrates in which a thin film of copper is deposited on the surface of the aluminium plate by electroplating or chemical plating techniques. This copper film enhances the electrical conductivity and thermal efficiency of the aluminium substrate due to its excellent electrical and thermal conductivity. Copper coated aluminium substrates are particularly suitable for high frequency circuits and high precision circuits.

Insulation Coated Aluminium PCB

Insulation coated aluminium substrates are made by applying a layer of insulating material to the surface of an aluminium plate through a coating process. The coating process makes the surface of the substrate smoother, which improves the stability and reliability of the circuit. Insulation coated aluminium substrates are widely used in electronic products with general performance requirements.

Laminated Insulated Aluminium PCB

Laminated insulating aluminium pcb is made by combining aluminium sheets with insulating materials under high temperature and pressure. The lamination process not only enhances the structural robustness of the aluminium substrate, but also improves its electrical properties.Laminated insulating aluminium substrates are particularly suitable for electronic products that require high mechanical strength and electrical properties.

Classified according to use

High Power Aluminium Heat Sinks

High power aluminium based heat sinks are designed to withstand the harsh environments of high power electronic devices such as power supplies and motor drivers. These substrates are subjected to high currents and temperatures, and are therefore often made of thicker aluminium and high-quality insulating materials. High-power aluminium-based heat sinks provide excellent thermal and electrical performance, ensuring stable operation under high load conditions.

Aluminium-based conduction plates for high frequency applications

Aluminium-based conductive panels for high-frequency applications are mainly used in high-frequency circuits such as wireless communication equipment and radar systems. These substrates need to have excellent electrical and thermal conductivity to reduce signal loss and improve heat dissipation. Aluminium-based conduction plates for high-frequency applications are typically manufactured using highly conductive metals and high-performance insulating materials.

High Precision Aluminium Base Stabilizers

High-precision aluminium-based stabilised panels are designed for high-precision electronic devices, such as instrumentation and sensors. These substrates have extremely high requirements for dimensional accuracy, surface flatness and long-term stability. High Precision Aluminium Base Stabilized Plates are manufactured using high precision production processes and high quality raw materials to ensure excellent performance and reliability of the equipment.

Aluminium Reinforced Plates for Special Applications

Aluminium reinforced panels for special applications are designed to meet the needs of special environments and specific applications such as aerospace and military. These substrates need to be extremely reliable, durable and environmentally adaptable. Aluminium reinforced panels for special applications are often manufactured using special materials and unique manufacturing processes to meet the requirements of extreme conditions.

Classification by structure

Single-ply structural aluminium composite panels

Aluminium composite panels with a single layer of aluminium and a layer of insulating material are simple and relatively low-cost. It is suitable for applications where costs are controlled and electrical performance is not required.

Aluminium Heat Sinks with Double Layer Construction

The double-layer construction of aluminium-based heat sinks consists of two layers of aluminium and one layer of insulating material stacked on top of each other, exhibiting good heat dissipation and mechanical strength. The double-layer design helps to reduce electromagnetic interference and enhance the stability of signal transmission. The dual-layer construction of aluminium-based heat sinks is ideal for electronic devices that require high electrical and thermal performance.

Multi-layer laminated aluminium-based high-performance boards

Multi-layer laminated aluminium-based high-performance boards are complex and costly structures consisting of alternating layers of aluminium and insulating materials. The laminated design further improves thermal and electrical performance while reducing electromagnetic interference. Multi-layer stacked aluminium high-performance panels are ideal for high-performance, high-precision electronic devices.

Aluminium PCB performance

1.Heat dissipation

At present,many double-sided boards, multilayer boards, high density, high power, heat dissipation is difficult. Conventional printed board substrates such as FR4, CEM3 are bad conductors of heat, interlayer insulation, heat emanation.The local heat of electronic equipment is not excluded, resulting in high temperature failure of electronic components, and aluminium substrate can solve this heat dissipation problem.

2.Thermal expansion

Thermal expansion and contraction is the common nature of matter, the coefficient of thermal expansion of different substances is different. Aluminium-based printed circuit boards can effectively solve the heat dissipation problem, thus alleviating the thermal expansion and contraction of different substances of the components on the printed circuit boards, and improving the durability and reliability of the whole machine and electronic equipment. Especially to solve the SMT (surface mount technology) thermal expansion and contraction problems.

3.Dimensional stability of aluminium-based printed circuit boards, obviously the size is much more stable than the insulating material printed circuit boards. Aluminium-based printed circuit boards, aluminium sandwich panels, heated from 30 ℃ to 140 ~ 150 ℃, the size change of 2.5 ~ 3.0%.

Aluminium PCB use

1.Audio equipment: input and output amplifiers, balanced amplifiers, audio amplifiers, preamplifiers, power amplifiers, etc.

2.Power supply equipment: switching regulator, DC/AC converter, SW regulator, etc.

3.Communication electronics equipment: high-frequency amplifiers, filtering appliances, and transmitter circuits.

4.Office automation equipment: motor driver, etc.

5.Automobile: Electronic regulator, ignition, power controller, etc.

6.Computer: CPU boards, floppy disk drives, power supply units, etc.

7.Power modules: converters, solid state relays, rectifier bridges, etc.

8.Lamps and lanterns: With the promotion of energy-saving lamps, the aluminium substrate applied to LED lamps has also begun to be applied on a large scale.

Aluminium PCB,as a high-performance metal substrate, has been widely used in the electronics and LED industry. Its excellent heat dissipation performance, good thermal expansion control and stable dimensional characteristics make it an indispensable part of many electronic devices. From audio equipment to power supply devices, from communication electronics to office automation, aluminium substrates provide reliable solutions for various application scenarios with their unique features and advantages.

Product Name:Aluminum PCB

Material:aluminum base

Thickness: 1.0mm

Copper thickness: 1/OZ

Surface technology: Lead-Free Hasl

Solder mask: White/Black/

Silk screen: White

Minimum line width/spacing: 3mil

Minimum through-hole: 0.3mm

Application:LED lamp pcb

iPCB Corporation provides support for PCB Prototype and Electronic Manufacturing. You can request consultation or quotation for PCB, PCBA and ODM here, please contact email: sales@ipcb.com

We will respond very quickly.