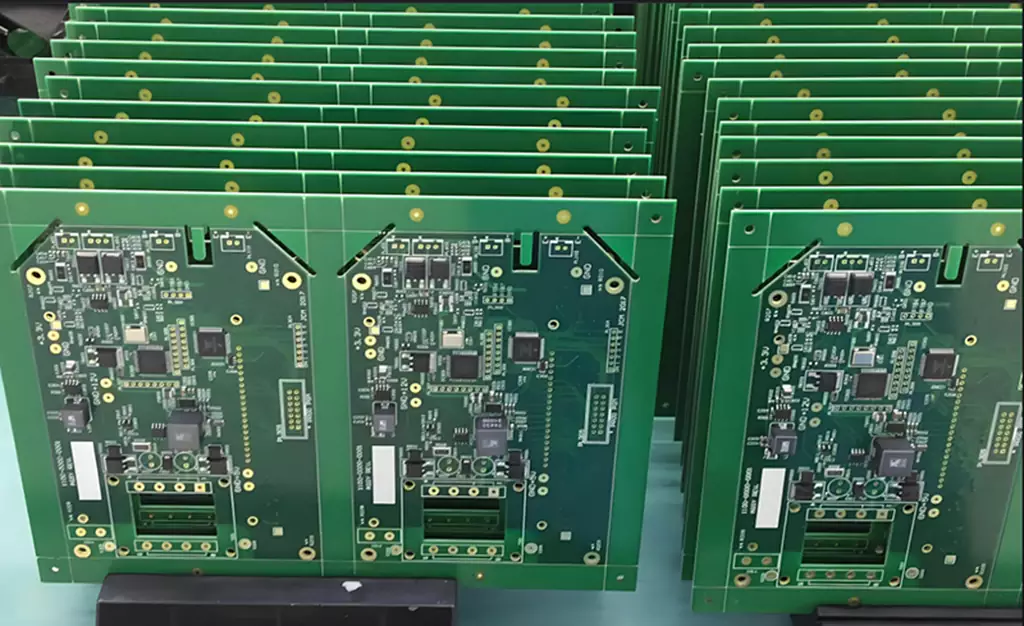

Product Name:Andriod PCBA

Material:FR4,PTFE

Thickness: 1.6mm

Copper thickness: 1/OZ

Surface technology: Enig/OSP

Solder mask: Red/Black

Silk screen: White

Minimum line width/spacing: 3mil

Minimum through-hole: 0.3mm

Application:Andriod

Android PCBA is a crucial component of an Android device, providing the electrical connections and support in the device.The merit of the PCBA has a direct impact on the performance and stability of the Android device, therefore, as Android smart devices become more popular, the technology and quality of production of PCBA is also improving.

The core structure of an Android PCBA consists of multiple parts, including the printed circuit board (PCB) and the electronic components soldered to it.The electronic components can include processors, memory chips, sensors,etc.,which work together to perform the various functions of the device.During the manufacturing process,the PCBA process needs to go through multiple processes such as layout design,soldering, testing, etc. to ensure the performance and reliability of the final product.

Characteristics of Android PCBA:

Reliability.

The reliability of Android PCBA is one of its most basic characteristic requirements.Highly reliable PCBAs are able to function properly in a variety of harsh environments,including high temperatures,humidity,and vibration conditions. In order to improve reliability,manufacturers usually choose high-quality materials and conduct strict quality control during the production process, including functional and aging tests,to ensure stability and durability in long-term use.

Low Power Consumption:

As the battery life requirements of smart devices continue to increase,Android PCBA must be characterised by low power consumption.This feature not only extends the life of the device,but also helps to reduce heat generation,thereby improving overall performance.Manufacturers often adopt energy-efficient design concepts and efficient power management schemes to optimise the power consumption of their circuits.

Highly Integrated:

The high level of integration in Android PCBA is key to meeting the size and functionality requirements of modern smart devices.Through fine layout design, more electronic components can be integrated in a limited space.High integration not only reduces the size of the device,but also improves the speed and stability of data transmission, which is especially important for high-performance applications.

Good thermal performance:

In high-performance applications,the heat generation problem of Android devices cannot be ignored.Therefore,Android PCBA need to have good thermal performance to prevent overheating that can lead to system failure.Manufacturers can optimise circuit design and select appropriate thermal materials to enhance heat dissipation and ensure that the system operates within the normal operating temperature range.

Compatibility:

Android PCBAs need to be compatible with various hardware and software platforms.Due to the openness of the Android system,device manufacturers usually need to test on different versions of Android to ensure the compatibility of the PCBA.Also,support for multiple communication interfaces (e.g.,USB,Bluetooth, Wi-Fi, etc.) is part of the compatibility to improve device connectivity.

Production Process:

The production process of Android PCBA (Printed Circuit Board Assembly) is a complex and systematic process involving multiple links, each of which has an important impact on the quality of the final product.

1.Design Phase

Before the production of Android PCBA,the first thing you need to do is to design the circuit board.Design engineers use professional PCB design software to convert the circuit design into a PCB layout. At this stage, key design parameters include circuit layout,component selection and connection relationships.After the design is completed,the engineer will conduct a design review to ensure that the function of the circuit can be achieved and meet the specifications.

2.Production of circuit boards

After the design is confirmed,the circuit board production stage.The production process includes the following steps:

Material Preparation:Prepare PCB raw materials according to the design drawings,usually multi-layer insulated substrates.

Etching:On the substrate through photolithography and chemical etching methods,to remove unnecessary copper layer, the formation of the desired circuit pattern.

Drilling:Drill holes in the circuit board for subsequent insertion and electrical connection of components.

3.Component Mounting

After completing the PCB fabrication,the components will be mounted.This process is generally automated using a SMD machine (SMT),the specific steps include:

Printing solder paste:In the mounting area coated with solder paste,for subsequent components to provide the basis for soldering.

Placement of components:The components are accurately placed onto the solder paste by the placement machine.

Reflow Soldering:The board is heated in a reflow oven so that the solder paste melts and connects to the component feet to form a stable solder joint.

4.Insertion of components

For components that need to be manually assembled (e.g., high-power components, interfaces, etc.),the plug-in method is used. Specific steps include:

Component insertion:Insert the manually assembled components into the preset jacks of the board.

Wave soldering:The inserted components are soldered to the circuit board by wave soldering technology to form an electrical connection.

5.Quality Inspection

After completing the soldering,various quality tests are performed to ensure that the PCBA meets the design specifications. Common inspection methods include:

Visual inspection:Visual inspection of the PCB to see the solder joints and components assembly.

Function test: Through special test equipment,the Andriod PCBA function of the test to ensure that it works properly.

Aging test: The PCBA will be placed in a specific environment for aging, in order to detect its long-term stability and durability.

6.Final Assembly

After the inspection of qualified Andriod PCBA will enter the final assembly stage,the final product shell,screen and other accessories will be assembled at this time.After assembly, the device will undergo a final function test to ensure that the overall work properly.

7.Packaging and Delivery

Finally, the product will be packaged and ready for delivery to the customer.The packaging should ensure that the product will not be damaged during transport.

As a core component of Android devices,the design,manufacturing and quality control of Android PCBA is crucial.Through continuous technological innovation and process optimisation, the performance and reliability of Android PCBA has been continuously improved,providing a solid foundation for the development of modern smart devices.

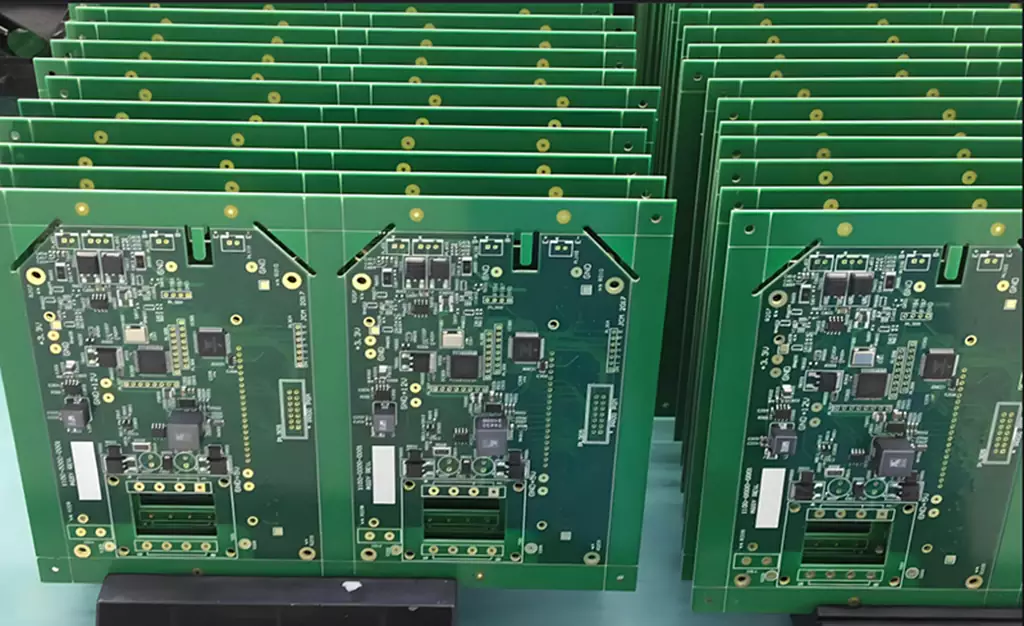

Product Name:Andriod PCBA

Material:FR4,PTFE

Thickness: 1.6mm

Copper thickness: 1/OZ

Surface technology: Enig/OSP

Solder mask: Red/Black

Silk screen: White

Minimum line width/spacing: 3mil

Minimum through-hole: 0.3mm

Application:Andriod

iPCB Corporation provides support for PCB Prototype and Electronic Manufacturing. You can request consultation or quotation for PCB, PCBA and ODM here, please contact email: sales@ipcb.com

We will respond very quickly.