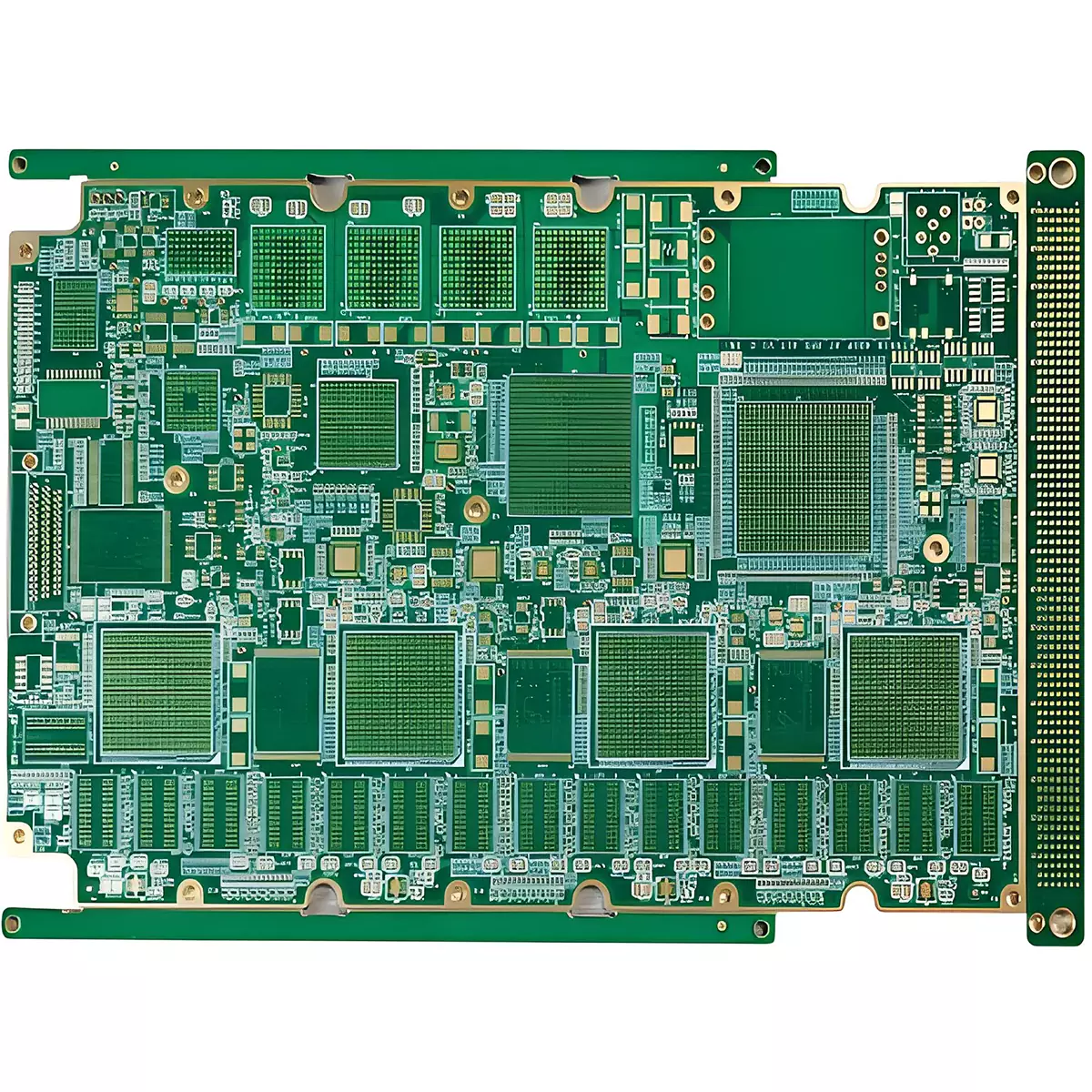

Product Name:Blank PCB

Material:FR-4,Ceramic,metal

Thickness: 1.6mm

Copper thickness: 1/1oz

Surface technology: Glod,ENIG,HASL

Solder mask: Green

Silk screen: White

Minimum line width/spacing: 6/6mil

Minimum through-hole: 0.2mm

Application: Communication, Computer, Industrial Control, Home Appliances and Automotive

A blank pcb is a type of circuit board that does not undergo circuit board control processing and printed circuit artwork,and it does not include any circuit components in its manufacturing process. Blank circuit boards usually have conductive tracks and enough pad space to allow users to freely design circuit layouts and assemble circuit components.

Blank pcb can be divided into two main categories: copper-clad boards and metal-backed boards.Copper-clad boards,as the most commonly used type of blank circuit boards, are characterised by a structure in which both the top and bottom surfaces of the insulated substrate are covered with a layer of copper foil. Metal backed boards are constructed by covering the insulating material with a layer of copper foil on both the top and bottom surfaces of the insulating substrate. Aluminium. Tungsten and other metal layers to build conductive routes.

Blank circuit boards are often used to make printed circuit boards and other electronic components.A printed circuit board is a carrier for connecting electronic components and usually consists of a blank circuit board and a circuit design. In addition to this, blank pcb can also be used to make LED lights,smartphone,Tablet PCs.Automotive electronic devices and so on.

Advantages and disadvantages of blank pcb:

Advantages:

Flexible design: users are free to plan the circuit layout and assemble circuit components;

Efficient production: the production cost of blank pcb is relatively low, so the production efficiency is higher;

Convenient storage: no need to worry about component damage or deformation, easy to store;

Cost saving: compared with pre-fabricated boards, the cost of blank circuit boards is cheaper.

Disadvantages:

Skill requirements: blank pcb needs to be designed by themselves, so they need to have the corresponding design and assembly skills;

Low security: lack of component protection, vulnerable to malicious tampering.

Differences between blank circuit boardsand printed circuit boards

Differences in production processes

Blank pcb and printed circuit boards in the production process there are significant differences, mainly reflected in the following three points:

1.Blank pcb,as a new,not yet installed any components of the basic circuit board, through chemical etching and light painting and other complex processes to form the required lines and holes. This process is often used to create circuit boards with individual requirements.

2.Printed circuit boards are based on a blank circuit board,through the printed copper technology to deposit lines. There are various types of printed circuit boards, including single-sided boards, double-sided boards and multilayer boards. Double-sided boards and multilayer boards, these types are widely used in various types of electronic products.

3.The two are also different in material and performance. Blank circuit boards are mainly made of glass fibre plates, while printed circuit boards can be made of FR-4, FR-2, metal substrates and other materials according to actual needs.

Difference in Application Scenarios

Blank pcb and printed circuit boards have their own applications:

Blank circuit boards are often used to meet the needs of personalised circuit boards, such as DIY electronics enthusiasts. Prototyping. Small batch production.

Printed circuit boards are highly regarded for their wide range of applications, such as mobile phones. Computer. Home appliances. Automotive electronics and so on. They are capable of carrying a variety of integrated circuits and devices to achieve the diverse functions of electronic products.

Price Differences

In terms of price, there is also a certain gap between blank pcbs and printed circuit boards:

Blank pcb is usually more expensive than printed circuit boards due to their relatively high cost as they need to go through tedious processes such as chemical etching and photolithography.

In contrast, printed circuit boards are less expensive to produce. This is mainly due to its simple process of printing and laminating copper as well as the advantage of mass production.

Product Name:Blank PCB

Material:FR-4,Ceramic,metal

Thickness: 1.6mm

Copper thickness: 1/1oz

Surface technology: Glod,ENIG,HASL

Solder mask: Green

Silk screen: White

Minimum line width/spacing: 6/6mil

Minimum through-hole: 0.2mm

Application: Communication, Computer, Industrial Control, Home Appliances and Automotive

iPCB Corporation provides support for PCB Prototype and Electronic Manufacturing. You can request consultation or quotation for PCB, PCBA and ODM here, please contact email: sales@ipcb.com

We will respond very quickly.