Flexible printed circuits (FPC) are widely used in modern electronic devices due to their unique flexibility, light weight and high density. According to the number of layers, FPC can be divided into single-layer, double-layer and multi-layer, and each type is different in structure, performance and application. This article introduces the differences between single-layer, double-layer and multi-layer FPC in detail.

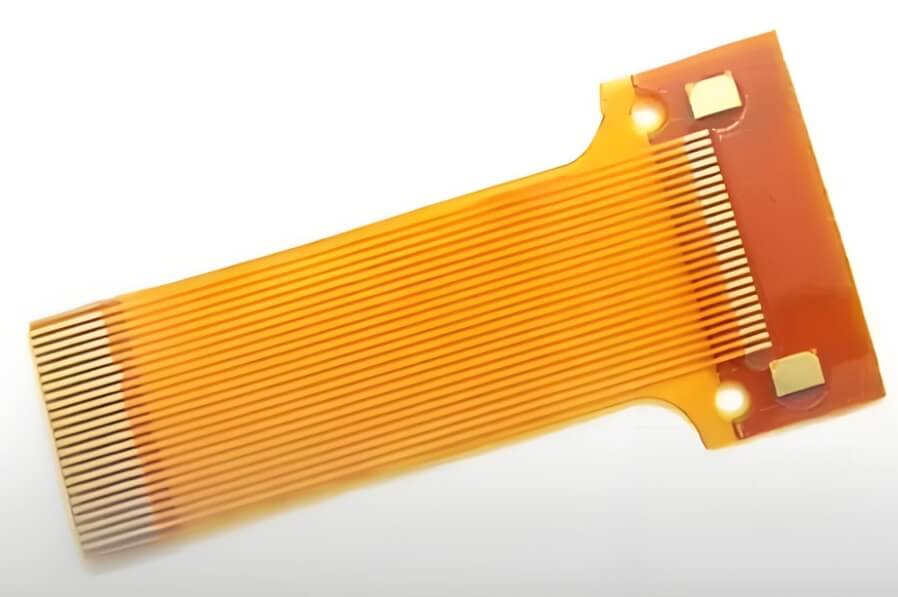

Single-layer FPC

Single-layer FPC is the simplest type of flexible circuit board, consisting of a layer of conductive copper foil and a substrate. The copper foil is engraved with a circuit pattern and the surface is covered with a protective film.

Structure:

Substrate (such as polyimide or PET)

Copper foil

Cover layer (protective conductive copper foil)

Features:

Simple structure: There is only one conductive layer, the manufacturing process is relatively simple, and the production cost is low.

Good flexibility: The single-layer structure provides excellent flexibility and can meet complex bending and folding requirements.

High reliability: Due to the simple structure, the failure rate is low and it is suitable for simple circuit connections.

Application:

It is very suitable for applications that require simple connections and high flexibility, such as printers, scanners, and simple display connections.

Single Layer FPC

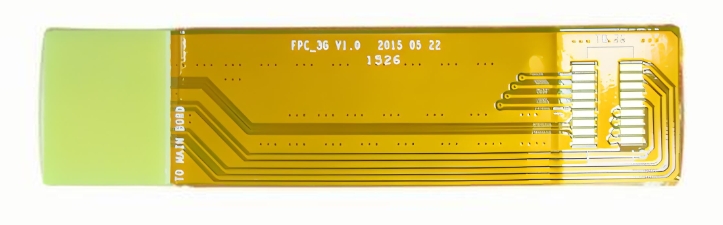

Double-layer FPC

Double-layer FPC contains two layers of conductive copper foil separated by a substrate. The two layers of copper foil are electrically connected through plated through holes.

Structure:

Cover layer

Top copper foil

Substrate

Bottom copper foil

Cover layer

Features:

More complex circuit design: The double-layer structure allows circuit patterns to be etched on two layers of copper foil and electrical connections to be made between layers through vias.

Increase circuit density: Compared with single-layer FPC, double-layer FPC can accommodate more circuits, increasing circuit density and complexity.

Improve reliability: The double-layer structure better meets the needs of applications with higher circuit reliability requirements.

Application:

Widely used in devices that require more complex circuit designs, such as mobile phones, digital cameras, and medical devices.

Double Layer FPC

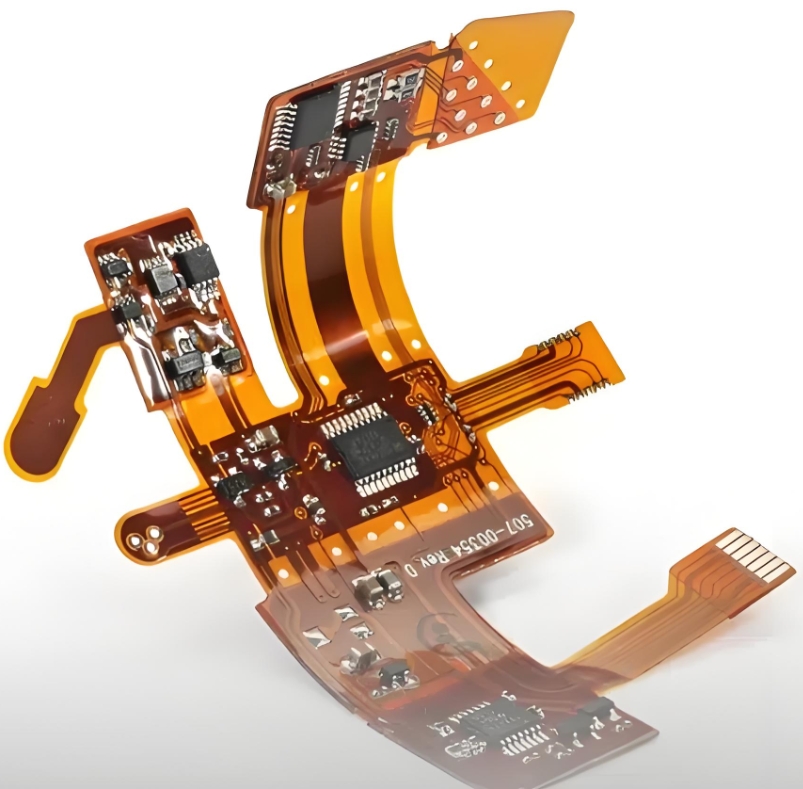

Multilayer FPC

Multilayer FPC is made of multiple layers of conductive copper foil and substrate stacked and connected by adhesive layers, and each layer is connected together by vias.

Structure:

Cover layer

Top copper foil

Substrate

(Adhesive + copper foil + substrate) × N (repeated multilayer structure)

Bottom copper foil

Cover layer

Features:

High-density circuit design: Multilayer structure enables more complex and high-density circuit design, suitable for demanding application scenarios.

Greater design flexibility: The circuit can be divided into multiple layers according to design requirements, making full use of space and optimizing circuit layout.

Improved signal integrity: Multilayer design can better manage signal paths, reduce electromagnetic interference and improve signal integrity.

Application:

Mainly used in high-end electronic devices such as modern smartphones, tablets, aerospace equipment and high-precision medical instruments.

Multi-Layer FPC

Single-layer, double-layer, and multi-layer FPCs each have unique advantages and application scenarios. Single-layer FPCs are suitable for simple circuit connections due to their simplicity and high flexibility. Double-layer FPCs have greater structural complexity and higher circuit density, while multi-layer FPCs are suitable for high-end and precision applications because they can support high-density and complex designs. Understanding these differences can help you choose the right FPC type based on your specific requirements and optimize the performance and reliability of your electronic devices.