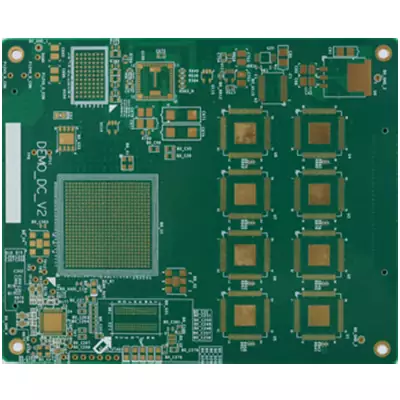

Product Name: FR-4 PCB

Material: FR-4 CCL

Quality standard: IPC 6012

Layers: 1L - Multilayer PCB

Thickness: 0.1mm-12mm

Copper thickness: 0.5-12oz

Surface technology: silver, gold, tin

Solder mask: green, red, blue, black, white

Screen printing: black, white

Application: Simple electronic products

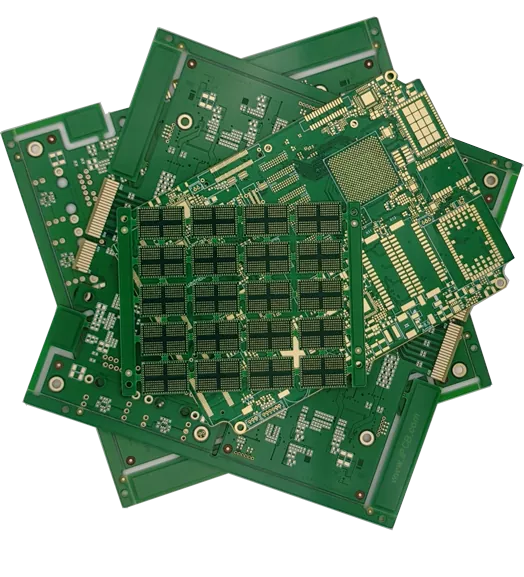

FR-4 PCB is the most commonly used circuit board in our daily lives. In fact, FR-4 is not a material name, but a material grade, which represents the flame resistance level of resin materials that must be able to self extinguish after combustion. Therefore, there are many types of FR-4 grade materials used in general circuit boards, but most of them are PCB materials made of Tera Function epoxy resin, fillers, and fiberglass.

FR-4 PCB circuit boards are generally referred to as FR-4 Epoxy Glass Cloth, insulation board, epoxy board, epoxy resin board, brominated epoxy resin board, FR-4, fiberglass board, fiberglass board, FR-4 reinforcement board, FPC reinforcement board, flexible circuit board reinforcement board, FR-4 epoxy resin board, flame-retardant insulation board, FR-4 laminated board, epoxy board, FR-4 light board, FR-4 fiberglass board, epoxy glass cloth board, epoxy glass cloth laminated board, and circuit board drilling pad according to their different uses in the industry.

The electrical insulation performance of FR-4 PCB is stable, with good flatness, smooth surface, no pits, and thickness tolerance standards. Therefore, FR4 PCB board is suitable for products with high-performance electronic insulation requirements, such as FPC reinforcement board, PCB drilling pad, fiberglass meson, potentiometer carbon film printed fiberglass board, precision planetary gear, precision testing board, electrical equipment insulation support partition, insulation pad, transformer insulation board, motor insulation parts, grinding gears, electronic switch insulation board, etc.

FR-4 epoxy fiberglass cloth substrate is a type of substrate that uses epoxy resin as the adhesive and electronic grade fiberglass cloth as the reinforcing material. Its adhesive sheet and inner core thin copper-clad laminate are important substrates for making printed circuit boards.

FR-4 PCB Board

Why do most PCB boards choose FR-4?

In the field of electronic manufacturing, FR-4 material has become the preferred choice for PCB manufacturing due to its excellent performance and wide range of applications. So why choose FR-4 PCB?

1. FR-4 PCB is a composite material made by mixing glass fiber and flame-retardant epoxy resin. It has become a leader in the electronics industry due to its excellent flame retardant performance and stable electrical characteristics. Among numerous A-level board brands, such as Shengyi, KB, ITEQ, etc.

2. Flame retardant performance is crucial in the safety design of electronic devices. FR-4 PCB contains special chemicals that can slow down the spread of fire and protect electronic devices from damage in the event of a fire. This flame retardancy makes FR-4 PCB the preferred material in electronic devices.

3. The mechanical and electrical characteristics of FR-4 PCB make FR-4 not only flame retardant, but also excellent in mechanical and electrical properties. Its tensile strength and compressive strength are as high as 65000 psi and 38000 psi, respectively, which makes FR-4 PCB perform well under mechanical pressure. At the same time, its electrical performance is also very stable, and it can maintain good insulation performance in both dry and humid environments.

4. The stability and durability of FR-4 PCB are one of the reasons why it is popular. It has extremely high dimensional stability and will not deform due to changes in temperature or humidity. In addition, FR-4 PCB also has the characteristics of radiation resistance, chemical corrosion resistance, and thermal shock resistance, which enables it to maintain performance in various harsh environments.

5. With the increasing awareness of environmental protection, the environmental characteristics of FR-4 PCB have also been valued. Its flame retardant rating reaches 94V-0, which means it produces almost no harmful gases when burned, making it more environmentally and human health friendly.

6. The widespread use of FR-4 PCB is one of the reasons for its popularity. Whether in the fields of consumer electronics, communication equipment, automotive electronics, or aerospace, FR-4 PCB can play its unique role. Its high dielectric strength, bending strength, impact strength, and tensile strength enable it to meet various complex circuit design requirements.

FR-4 PCB occupies an important position in the PCB field due to its excellent performance, stability, and environmental characteristics. It is not only a reliable assistant for electronic engineers, but also a guarantee for the safe and stable operation of modern electronic devices. Choosing FR-4 PCB means choosing a reliable, efficient, and environmentally friendly electronic material.

Product Name: FR-4 PCB

Material: FR-4 CCL

Quality standard: IPC 6012

Layers: 1L - Multilayer PCB

Thickness: 0.1mm-12mm

Copper thickness: 0.5-12oz

Surface technology: silver, gold, tin

Solder mask: green, red, blue, black, white

Screen printing: black, white

Application: Simple electronic products

iPCB Corporation provides support for PCB Prototype and Electronic Manufacturing. You can request consultation or quotation for PCB, PCBA and ODM here, please contact email: sales@ipcb.com

We will respond very quickly.