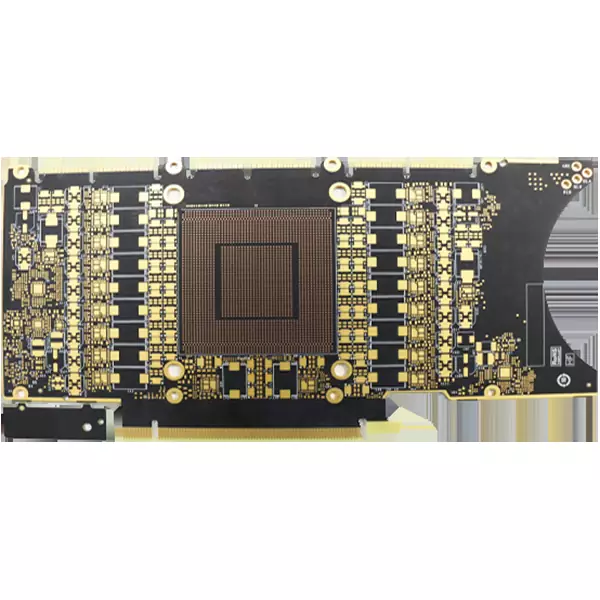

Product Name:High Speed PCB

Material:FR-4,Rogers,Arlon,Taconic

Thickness: 1.6mm

Copper thickness: 1/1oz

Surface technology: Glod

Solder mask: Red,Green

Silk screen: White

Minimum line width/spacing: 6/6mil

Minimum through-hole: 0.1mm

Application: Communications,computers,industry

High speed pcb, i.e., High speed printed circuit boards, are circuit boards designed for high speed electrical signals with transmission rates typically at 1 Gbps and above.In order to meet the high standards of high-speed differential signal transmission,precise matching of timing and electromagnetic compatibility, the manufacturing process of high speed circuit boards must use a series of specific process technology and materials.

High speed pcb is made of a wide variety of materials, including FR-4, Rogers, Arlon and Taconic, etc. FR-4, as a widely used traditional material, consists of a composite of glass fibre and epoxy resin, which has won the market's favour due to its excellent mechanical strength, heat resistance and good electrical characteristics. Rogers, Arlon and Taconic, on the other hand, belong to the category of high-performance materials, which show more excellent performance in terms of frequency response and signal transmission.

Advantages and disadvantages of different high speed pcb materials

FR-4 material

Advantage:FR-4 material is the preferred choice for many electronic devices due to its cost-effectiveness,excellent mechanical strength,stable heat resistance and ease of processing and moulding.

Disadvantage:However,FR-4 materials have a relatively poor frequency response and relatively high signal loss,which may limit their use in some high-performance applications.

Rogers

Strengths:Rogers materials are ideal for use in high-performance electronics due to their excellent frequency response, excellent signal transmission properties,and high degree of stability.

Disadvantage:Despite their outstanding performance, Rogers materials are costly and relatively complex to process, increasing manufacturing costs and time.

Arlon

Strengths:Arlon materials are also known for their high frequency response,excellent signal transmission and stability,making them ideal for electronics that demand the highest levels of performance.

Disadvantage:Similar to Rogers,Arlon is more costly and more difficult to process,which may limit its use in a wide range of applications.

Taconic

Strengths:Taconic materials also exhibit high frequency response, good signal transmission and stability, making them indispensable for high-performance electronic devices.

Disadvantage:Taconic materials are also costly and complicated to process, placing high demands on the technical level of manufacturers.

In high speed signal transmission, the interference and attenuation to which the signal is subject increases due to its elevated frequency. In order to ensure stable signal transmission, high speed PCB boards must use a series of special materials and processes. Common materials used for high speed PCBinclude FR-4, Rogers RO4003C,Isola DE305 and so on.These materials not only have a low dielectric constant (e.g., Rogers RO4003C has a dielectric constant of about 3.38), but also have very low loss (at 10GHz, Rogers RO4003C has a loss tangent of only 0.0027), which effectively reduces signal loss and distortion in the transmission process and ensures signal clarity and integrity.

When designing high speed PCB,engineers need to give full consideration to signal integrity and impedance matching.In the high-speed digital signal transmission process, any small signal distortion may lead to a significant decline in system performance.Therefore,designers need to reasonably plan the signal lines.

Ground and power line layout,try to shorten the signal transmission path,reduce path crossings,so as to avoid the signal backflow and crosstalk phenomenon.For example,in the layout process, you can use the ‘daisy chain’ type wiring, so that the signal lines are connected sequentially in a certain order to reduce the mutual interference between the signals.At the same time, through the precise control of line width.Line spacing and layer spacing and other parameters, such as the line width control in 0.1mm to 0.3mm between the line spacing to maintain more than 0.2mm,and reasonable set layer spacing to ensure that the signal line impedance matching.This fine regulation can not only enhance the stability and reliability of signal transmission,but also effectively reduce signal reflection and standing wave phenomenon,improve the overall performance of the system.

The manufacturing process of high speed PCB also requires the use of advanced processes and equipment.In order to meet the requirements of high-speed signal transmission, these boards often need to use such as blind buried holes.Impedance control lines. Gold fingers and other special processes.Blind vias enable precise connection of internal circuits in multilayer PCBs while reducing interference in the signal transmission path.Impedance control circuits ensure that signals maintain a stable impedance value during transmission, reducing signal reflections and distortion. Gold fingers are gold-plated connectors used to provide reliable connections between PCBs and other electronic devices. During the manufacturing process, manufacturers need to strictly control such as line width and line spacing tolerances (usually within ±0.05mm). Interlayer thickness tolerance (controlled within ± 0.025mm) and surface finish and other process parameters. These strict controls not only ensure the quality and stability of the PCB board, but also improve productivity and reduce manufacturing costs.

Application areas of high speed pcb:

1.Communications industry: In this era of information explosion,high speed printed circuit board in the communications industry is called the application of the ‘mainstay’. They not only help 5G base stations to achieve high efficiency. They not only help 5G base stations to achieve efficient and stable signal transmission, so that the ‘Internet of Everything’ has become possible, but also widely used in optical communication equipment, making optical fibre transmission speed faster. Lower loss. In the field of satellite communications, high speed pcb is indispensable to ensure the clear transmission of satellite signals over long distances, allowing global communications without dead ends. In addition, radio communication equipment is also inseparable from the support of high-speed circuit boards, whether it is military communications. Nautical communications or civilian communications, high-speed circuit boards with its excellent performance and stability, for the normal operation of communications equipment to provide a solid guarantee.

2.Computer science and technology: In the field of computer science and technology, high speed circuit boards are ‘indispensable’. To the server, for example, high speed pcb as one of the core components of the server, its performance directly affects the server's processing speed and concurrency. In the design and manufacture of motherboards, the application of high speed circuit boards to make the motherboard wiring more delicate. Signal transmission is more rapid, thus enhancing the overall performance of the computer. In addition, the upgrading of graphics cards is also inseparable from the support of high speed pcb,it not only improve the transmission speed of the graphics card, but also enhance the stability and compatibility of the graphics card. In the field of solid state drives (SSD), the application of high-speed circuit boards is to allow data storage speed to achieve a qualitative leap, thus meeting the urgent needs of modern computers for high-speed data storage.

3.Industrial automation: In the field of industrial automation, the application of high speed pcb is also extensive and in-depth.They are widely used in programmable logic controllers (PLC), making the PLC can be faster.More accurate processing of various control instructions,thereby improving the operational efficiency and stability of industrial equipment.In addition,industrial switches,as one of the core devices of industrial automation networks,can not be separated from the support of high speed circuit boards.They not only achieve efficient communication between industrial equipment,but also enhance the reliability and safety of industrial automation networks. In the field of industrial controllers, the application of high speed pcb is to make the performance of industrial controllers has been comprehensively improved to meet the modern industry for high precision.High efficiency.High stability of the urgent needs of modern industry.

Product Name:High Speed PCB

Material:FR-4,Rogers,Arlon,Taconic

Thickness: 1.6mm

Copper thickness: 1/1oz

Surface technology: Glod

Solder mask: Red,Green

Silk screen: White

Minimum line width/spacing: 6/6mil

Minimum through-hole: 0.1mm

Application: Communications,computers,industry

iPCB Corporation provides support for PCB Prototype and Electronic Manufacturing. You can request consultation or quotation for PCB, PCBA and ODM here, please contact email: sales@ipcb.com

We will respond very quickly.