The selection of the bottom fill material for chip package is a complex and critical process, which directly affects the reliability and performance of chip package. The main function of the bottom fill material is to provide additional mechanical support and thermal stress buffer between the chip and the substrate to deal with the stress problems caused by the difference in the coefficient of thermal expansion (CTE) of different materials. The following are some important considerations for the selection of the bottom fill material for chip package:

1. Characteristics of bottom fill materials

High temperature resistance:

The bottom fill material needs to be able to remain stable in a high temperature environment to cope with high temperature processing during the packaging process.

Common high temperature resistant materials include organic silicone, epoxy resin, and new high temperature resistant chip UV glue.

Electrical insulation:

Th bottom fill material must have good electrical insulation to prevent the bottom of the chip from making electrical contact with other components or bases.

This is essential to ensure the normal operation of the circuit and prevent short circuits.

Adhesion:

The bottom fill material needs to be able to adhere firmly between the chip and the substrate to provide stable mechanical support and protection.

Flow ability:

The flow ability of the material is critical to the filling effect. High viscosity materials can ensure that they will not flow or penetrate into the chip during the filling process, but they also need sufficient flow ability to fully fill the gap between the chip and the substrate.

Coefficient of thermal expansion (CTE):

The CTE value of the bottom fill material should match the CTE value of the chip and the substrate to reduce the thermal stress caused by the difference in thermal expansion coefficient.

Curing speed and conditions: The curing speed and required temperature will affect production efficiency and cost. Fast curing can improve yields but may require higher temperatures, which may cause damage to some sensitive components.

Mechanical strength: Materials with high strength provide better protection and reduce the risk of chip damage when subjected to external shock or pressure.

Chemical stability: The bottom fill material should have good chemical stability and be able to resist chemicals that may be encountered in the packaging environment, such as detergents or solvents

2. Application scenarios of bottom filling materials

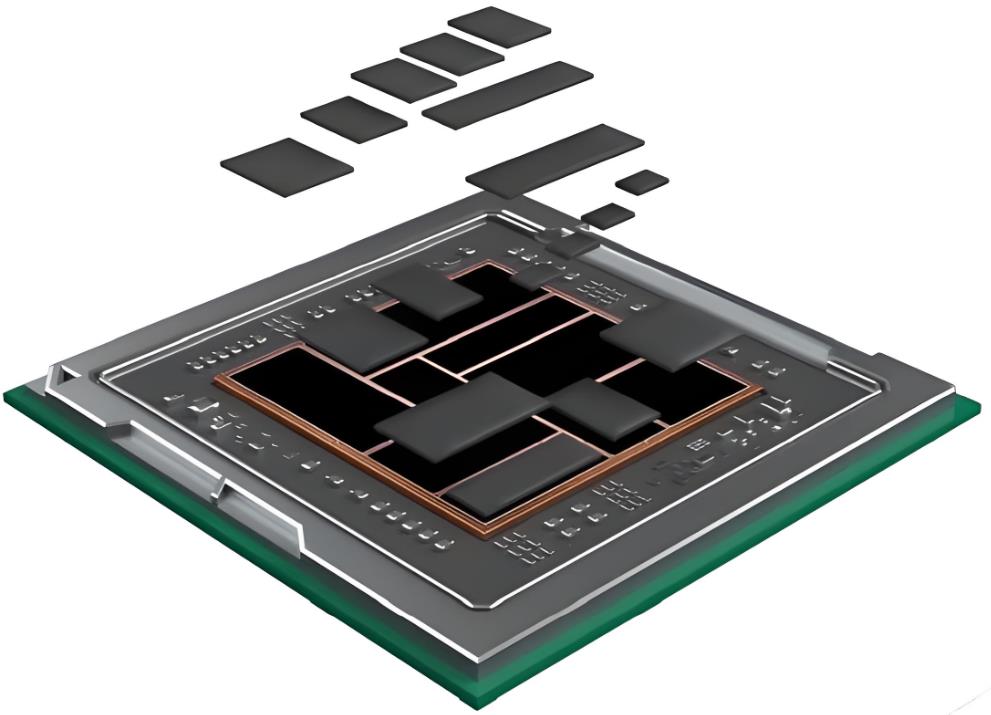

Flip-Chip Underfill:

It is used to fill the gap between the interconnection bumps of the chip and the package substrate, and the precision requirement is extremely high (micrometer level).

It is necessary to select high-purity, low-viscosity, and fast-curing materials to ensure the filling effect and process efficiency.

Ball Grid Array Underfill:

It is used to fill the solder balls interconnected between the package substrate and the PCB printed circuit board, and the precision requirement is relatively low (millimeter level). You can choose materials with good fluidity and mechanical protection properties.

3. Specific materials

Epoxy resin:

Epoxy resin is a common choice for bottom filling materials because it has good adhesion, insulation and high temperature resistance.

By adding toughening modifiers to the resin, the weakness of epoxy resin's insufficient flexibility can be overcome and the performance of the bottom filling glue can be improved.

Silicone:

Silicone also has good high temperature resistance and electrical insulation, and is suitable for packaging scenarios with high temperature requirements.

New high-temperature-resistant chip UV glue:

This type of material has the characteristics of fast curing, high temperature resistance and good adhesion, and is suitable for packaging scenarios with high requirements for process efficiency.

4. Other considerations

Cost:

The cost of the bottom filling material is also one of the factors to be considered when selecting. Under the premise of ensuring performance, materials with reasonable cost should be selected.

Environmental protection:

With the improvement of environmental awareness, the environmental protection of the bottom filling material has also become an important consideration. Non-toxic, harmless and recyclable materials should be given priority.

Process compatibility:

The bottom filling material should be compatible with the existing packaging process to ensure the stability and reliability of the process.

Process adaptability: The bottom filling material should be suitable for the filling method used, such as capillary flow, jet dispensing or preforms.

Chip Package

In summary, the selection of chip packaging bottom filling materials needs to be comprehensively considered based on specific application scenarios, material properties and cost factors. In the selection process, the advantages and disadvantages of various materials and their scope of application should be fully understood to ensure that the selected materials can meet the packaging process and performance requirements.