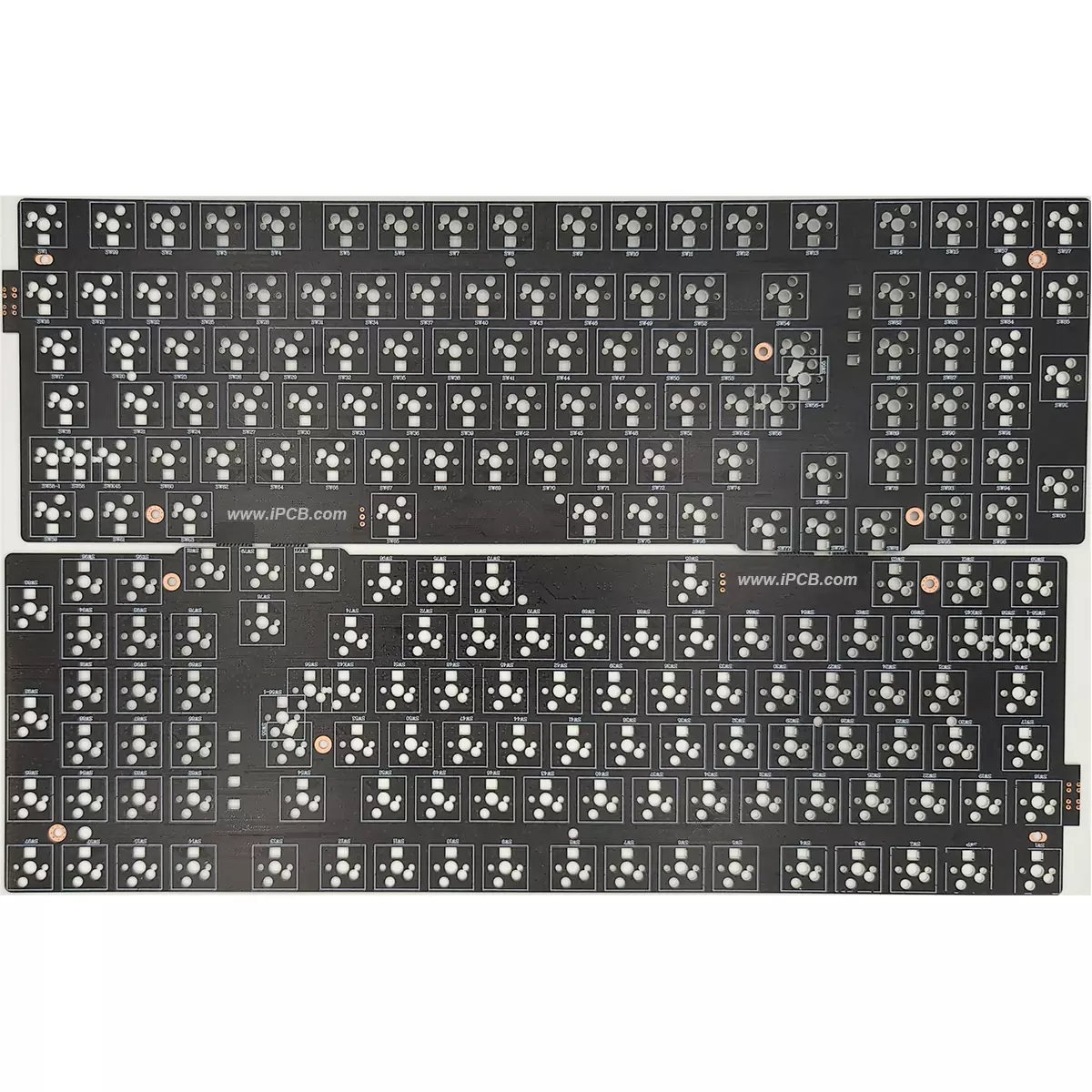

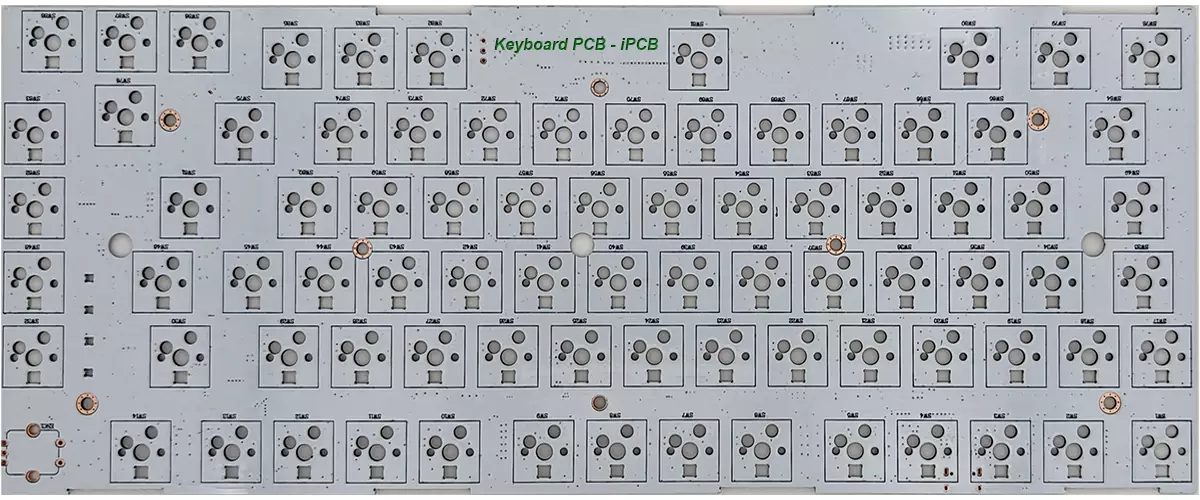

Product Name: Keyboard PCB

Material: FR-4 TG135

Layers: 2L

Thickness: 1.2mm

Copper thickness: 1oz

Surface technology: osp

Solder mask: black, white

Screen printing: white

Minimum line width/spacing: 6/6mil

Minimum through-hole: 0.3mm

Application: Keyboard

Behind every keystroke, there is a keyboard PCB that silently ensures the stable operation of the keyboard.

In the wave of the digital age, the keyboard, as an important tool for us to interact with computers, carries the key task of information input. The keyboard PCB is the core of the keyboard, responsible for signal transmission and stability. Keyboard PCB include single-layer PCB, double-layer PCB, multi-layer PCB, and flexible PCB, with complex manufacturing processes. High end keyboard PCB also integrate LED lighting effects, wireless technology, and IoT to enhance keyboard performance and intelligence.

Keyboard can be roughly divided into mechanical keyboard, membrane keyboard, and capacitive keyboard.

When a mechanical keyboard is pressed, it is similar to turning on a switch and connecting the connector. At this time, the switch is connected to the internal circuit board of the keyboard and sends an electrical signal to the computer through the wires in the USB or PS/2 cable connected to the keyboard. The computer receives this signal and interprets it according to the running program Here is a brief introduction to the complete closed-loop process of keyboard conduction sending commands to the computer receiving information for processing.

The membrane keyboard is an example of the membrane switch category, which refers to a membrane switch with a large number of keys arranged neatly and orderly. People are accustomed to calling it a membrane keyboard. Thin film keyboard is a type of keyboard that combines decoration and functionality that has become popular internationally in recent years. It consists of four parts: panel, upper circuit, isolation layer, and lower circuit. The membrane keyboard has a beautiful and innovative appearance, small size, light weight, and strong sealing. It has the characteristics of moisture resistance, dust prevention, oil pollution prevention, acid and alkali resistance, earthquake resistance, and long service life. Widely used in fields such as medical instruments, computer control, digital machine tools, electronic scales, postal and telecommunications, photocopiers, refrigerators, microwave ovens, electric fans, washing machines, remote controls, electronic game consoles, etc.

Capacitive keyboard are rare and expensive, and their feature is that when you open them, you will see a PCB circuit board. Capacitive keyboard have circuits, but there are no mechanical components soldered to the corresponding circuit board on the buttons. The tactile sensation is created using rubber, springs, and other materials. The opening and closing of the switch are determined by electrostatic capacitance induction, so it requires high technical expertise to achieve precise operation.

What is keyboard PCB?

Keyboard PCB is a printed circuit board used for keyboard. A keyboard PCB is a PCB board that integrates circuits and electronic components, responsible for receiving and transmitting signals from keys. The keyboard PCB is usually composed of double-layer FR4 PCB, including conductive paths, insulation layers, and necessary electronic components. These precise circuit designs ensure that every key on the keyboard can be accurately recognized and responded to without error.

The keyboard PCB is a switch connected to each key on the keyboard. When a key on the keyboard is pressed, the spring switch is activated. The switch is connected to the internal PCB board, which then sends a signal to the computer. The software converts keystrokes into actions.

keyboard PCB

Types of keyboard PCB

Single layer PCB: The most basic type of PCB, where all circuits are distributed on a flat surface, suitable for simple keyboard designs such as some thin film keyboard.

Multilayer PCB: A PCB that contains multiple circuit layers, providing more complex circuit designs and higher performance. It is commonly used in mechanical keyboard to support customization of more functions and key positions.

Flexible PCB: A PCB that can be bent, making keyboard design more flexible and suitable for ultra-thin or foldable keyboard.

Function of keyboard PCB

Signal transmission: The circuit on the PCB is responsible for converting button signals into electrical signals and transmitting them to the computer for processing.

Stability and Durability: High quality PCB design can improve the stability and durability of the keyboard, reducing the failure rate.

Customization and Functionality: For high-end mechanical keyboard, PCB design also allows users to customize key layout and programming macro commands, enhancing the user experience.

Manufacturing of keyboard PCB

The manufacturing of keyboard PCB involves complex process flows, including design, sampling, etching, drilling, copper plating, soldering, and other steps. Each step requires precise control to ensure the quality of the circuit board. With technological advancements, manufacturing processes are constantly being optimized to meet the market's demand for high-performance and high-precision keyboard.

With the development of technology, keyboard PCB are also constantly evolving. For example, adding LED lighting effects to the keyboard PCB not only enhances its appearance, but also achieves dynamic lighting effects through special circuit design. In addition, the integration of wireless technology makes keyboard more portable, while the convergence of IoT opens the door to intelligent keyboard.

Although the keyboard PCB is small, it is the key to keyboard performance and stability. In this digital age, behind every keystroke is the silent contribution of the keyboard PCB. Next time you type on the keyboard, imagine how those sophisticated PCB circuits and PCBA components work together to support our digital lives.

Product Name: Keyboard PCB

Material: FR-4 TG135

Layers: 2L

Thickness: 1.2mm

Copper thickness: 1oz

Surface technology: osp

Solder mask: black, white

Screen printing: white

Minimum line width/spacing: 6/6mil

Minimum through-hole: 0.3mm

Application: Keyboard

iPCB Corporation provides support for PCB Prototype and Electronic Manufacturing. You can request consultation or quotation for PCB, PCBA and ODM here, please contact email: sales@ipcb.com

We will respond very quickly.