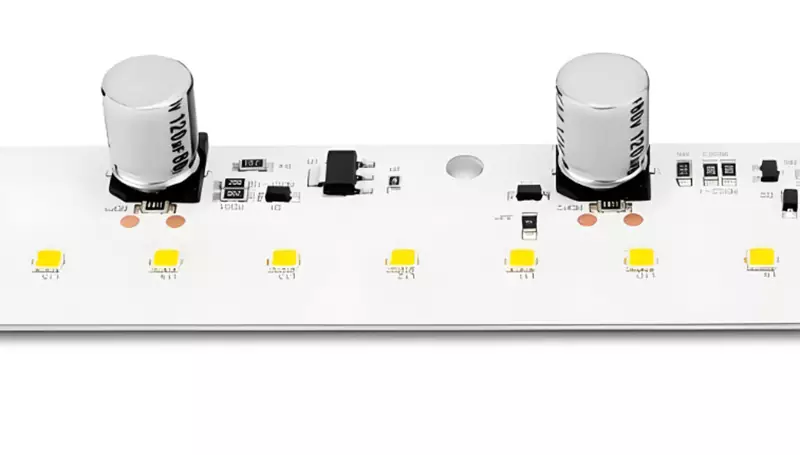

Product Name:Led Light PCB

Material:FR4,Copper PCB,Aluminum

Thickness: 1.0mm

Copper thickness: 1OZ

Surface technology: ENIG

Solder mask: White/Black/

Silk screen: White

Minimum line width/spacing: 3mil

Minimum through-hole: 0.3mm

Application:LED

LED light pcb is circuit board that use light emitting diodes (LEDs) as a light source. It is an important part of electronic devices, transmitting electronic signals and power supply through circuits and connectors for lighting functions.LED light boards are not only compact in appearance, but also highly integrated with multiple electronic components and circuits, making their design and manufacturing process more efficient.

The core part of the LED light circuit board is the LED, which is a semiconductor device that produces light through the flow of electric current.LEDs have the advantages of high brightness, low power consumption and long life, so they are widely used in the fields of lighting, display and decoration.

The basic principle of LED light circuit board is to direct the current to the LED through proper circuit design. Generally, LEDs require current limiting to prevent excessive current from damaging the LED. To achieve this, components such as resistors or current sources can be used to control the amount of current.

LED light pcb usually consist of a substrate, a circuit layer, a soldermask layer and a character layer. The substrate is the support structure of the board and is usually made of materials such as glass fibre reinforced epoxy resin (FR-4) or aluminium substrate. The circuit layer is the core part of the circuit board, which consists of copper foil and is used to transmit current and voltage. Soldermask is a layer of insulating material that covers the circuit layer and is used to prevent short-circuiting and oxidation of the circuit. The character layer is the text and symbols marked on the circuit board, used to identify the model and parameters of the circuit board.

The common materials of LED light pcb board mainly include substrate materials, conductive materials and packaging materials.These materials play an important role in the performance of the LED light pcb,heat dissipation effect and manufacturing process.

1.Substrate materials: LED light pcb substrate materials generally include FR-4, aluminium substrate, copper substrate and ceramics, etc. FR-4 is a common epoxy resin composite material, suitable for general LED applications, but poor heat dissipation performance. Aluminium substrates, on the other hand, are widely used for their excellent heat dissipation performance, especially in high-power LEDs. Copper substrate has better thermal conductivity, but the cost is relatively high, and it is suitable for occasions with very high requirements for heat dissipation. Ceramic substrate with its excellent thermal conductivity and insulation properties, suitable for high temperature environment and high power applications.

2.Conductive materials: in the LED light pcb, the conductive material is usually copper. This is because copper has good conductivity and processability.In order to improve the reliability of the line,sometimes also coated with a layer of nickel or gold on the copper layer to prevent oxidation and improve the quality of welding.

3.Encapsulation materials: LED encapsulation materials are usually used epoxy resin or silicone, these materials can not only protect the LED chip from the effects of the external environment, but also play a role in the optical through the role of ensuring that the light effect of play.

When designing the LED light circuit board,you also need to consider the choice of power supply and connection mode.LED lights are usually powered by DC power supply,you can choose to use batteries, adapters or power modules, etc..At the same time,the power supply needs to be connected to the LED light pcb,usually using socket connecting wires or welding and so on.

Features of LED light pcb board

1.High brightness: the led light circuit board is composed of LED light-emitting diodes with high brightness,which can achieve a brighter effect than traditional light bulbs.

2.Energy saving: compared with traditional light bulbs, led light circuit board is more energy efficient, can achieve a high energy efficiency ratio, reduce energy waste.

3.Durable: led light circuit boards have a long life, can reach tens of thousands of hours or more, greatly reducing the replacement cost.

4.Environmental protection: led light pcb does not contain mercury and other harmful substances, more friendly to the environment.

5.Diversification:led light pcb can be customized according to different needs, shape, size, colour and so on can be freely selected.

With its excellent performance and wide range of application prospects, LED light circuit board is leading the lighting industry to new heights. With the continuous progress of technology, LED light pcb will continue to innovate and bring more light and possibilities to our life.

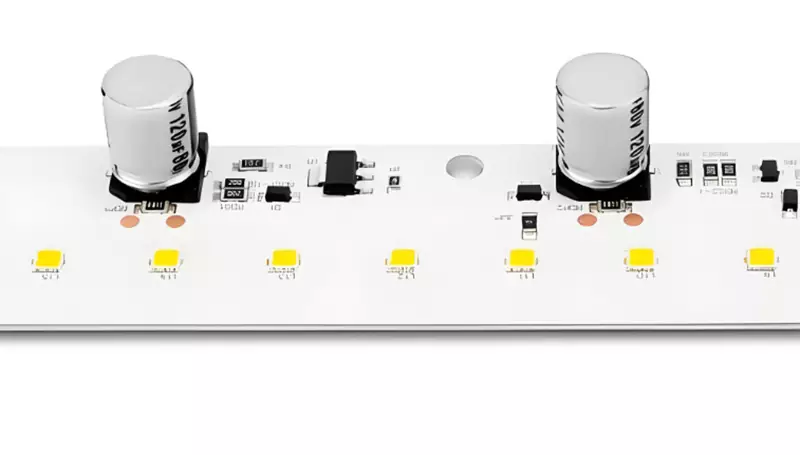

Product Name:Led Light PCB

Material:FR4,Copper PCB,Aluminum

Thickness: 1.0mm

Copper thickness: 1OZ

Surface technology: ENIG

Solder mask: White/Black/

Silk screen: White

Minimum line width/spacing: 3mil

Minimum through-hole: 0.3mm

Application:LED

iPCB Corporation provides support for PCB Prototype and Electronic Manufacturing. You can request consultation or quotation for PCB, PCBA and ODM here, please contact email: sales@ipcb.com

We will respond very quickly.