In an era dominated by the miniaturization and multifunctionality of electronic devices, such as smartphones, tablets, and wearables, High-Density Interconnection Printed Circuit Boards have become central to technological advancement. However, as the demand for smaller, lighter, and more capable devices grows, so too do the challenges facing PCB manufacturers.

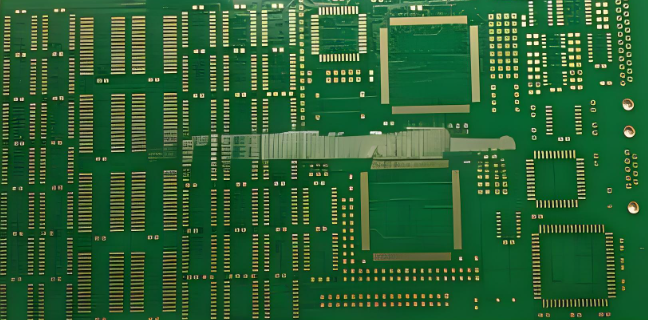

HDI PCB

The Drive for Miniaturization and Enhanced Performance:

The push towards miniaturization has resulted in ever-thinner conductor and insulating layers. Manufacturers are now producing PCBs where the insulation thickness dips below the critical threshold of 50 µm. This reduction results in several challenges: achieving dimensional stability and maintaining electrical performance, especially concerning signal impedance and insulation resistance, become increasingly difficult as trace density and width are pushed to the limits, often falling below 40 µm.

Traditional subtractive processes struggle to produce these fine traces, highlighting a pivotal shift towards additive manufacturing techniques. Although additive methods enable the creation of intricate circuit patterns, they come with their own set of challenges; primarily higher costs and limitations in production scale.

The Challenges of Layering and Cost-Effectiveness:

As the PCB industry continues to enhance layer counts to accommodate more components within compact designs, cost-effectiveness and process capabilities become critical points of contention. Advanced methods such as any-layer interconnection high-density (ALV HDI) designs are being implemented, but they are met with limitations in both performance scalability and increased manufacturing costs.

The challenge is further amplified in a competitive market where meeting consumer demand without escalating production expenses is paramount. Improved materials and processes must not only keep pace with shrinking technology but also optimize cost structures to remain viable.

5G Technology: A Game Changer for HDI PCBs:

The advent of 5G technology represents a transformative force across industries, promising to enhance the efficiency of technologies such as the Internet of Things (IoT), cloud computing, big data, and artificial intelligence. Officially promoted as a crucial initiative in 2019, the deployment of 5G infrastructure is expected to push the boundaries of HDI PCB technology.

The transition from concept to reality brings with it a host of challenges, but also opportunities for innovation within the PCB manufacturing sector. Manufacturers must prepare for 5G-related demands such as higher bandwidth, reduced latency, and improved power efficiency all of which are heavily reliant on advancements in HDI technology.

Innovations in Electroplating and Copper Foil Technology:

Recent innovations in manufacturing processes have emerged as potential solutions for some of the challenges in HDI PCB production. For instance, the carbon series direct electroplating system has gained traction among electronics manufacturers. This system not only simplifies and reduces costs associated with traditional electroless copper processes but also promotes sustainability by minimizing water consumption and wastewater generation, along with boosting energy efficiency.

Moreover, the latest smart devices demand ultra-thin copper foil, which serves as the foundation for the HDI circuitry. Achieving precise etching accuracy in forming copper interconnects is crucial; advancements such as the application of black hole technology in semi-additive processes for 3-micron copper foil are paving the way for high-quality HDI production.

Conclusion: Embracing Change and Facing Future Challenges:

As we continue to traverse the exciting yet challenging landscape of HDI PCB production, staying ahead demands adaptability and innovation. From enhancing material performance to adopting advanced manufacturing techniques, the industry must rise to meet the evolving needs of the electronics market, particularly as 5G technology reshapes expectations.

By addressing these challenges head-on and embracing new technologies, manufacturers can confidently navigate toward a future where HDI PCBs meet the needs of increasingly sophisticated electronic devices.