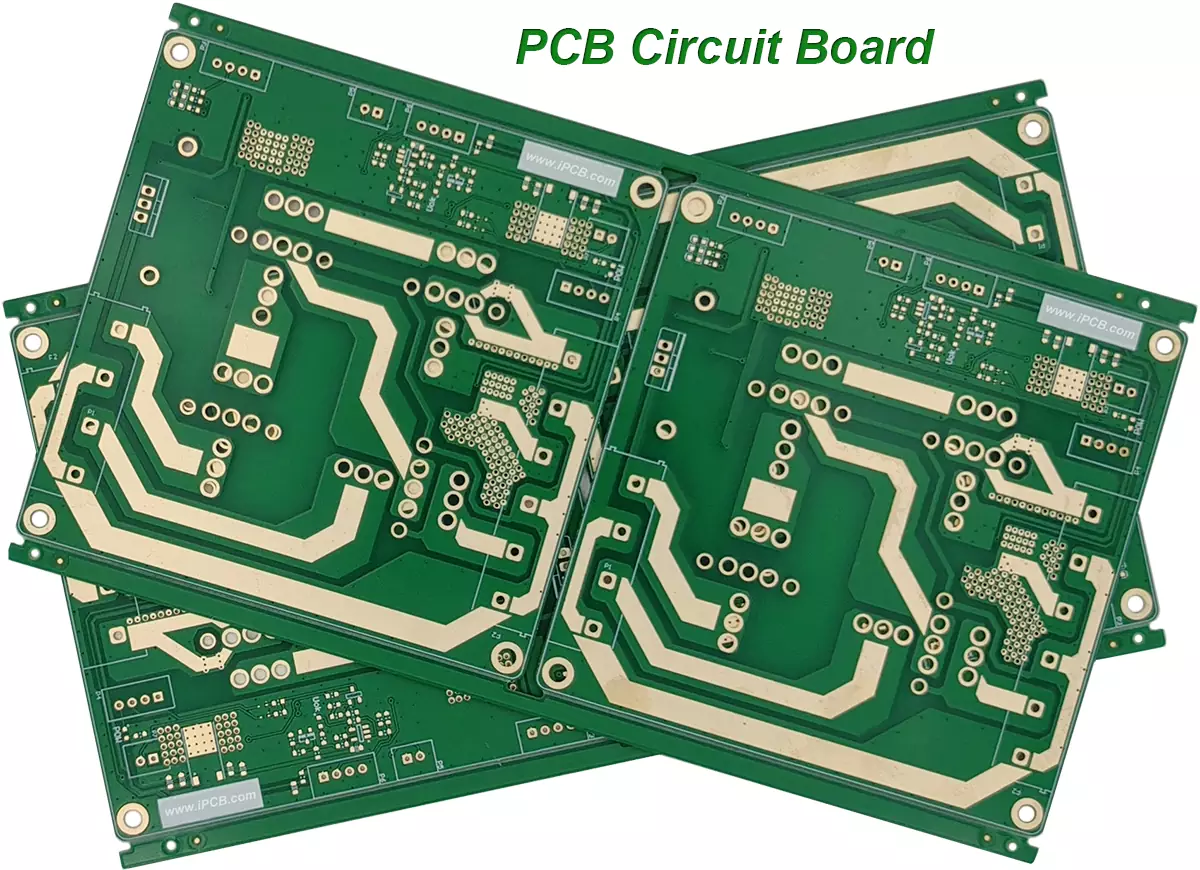

What is PCB Circuit Board? PCB board refers to printed circuit board, also known as circuit board or blank PCB. Currently, almost all electrical products in the world use PCB as the substrate for electronic components. The commonly used conductive material for PCB is copper foil, which covers the surface of insulating material and forms circuit patterns through chemical corrosion or mechanical processing. Wires, solder pads, and mounting holes for electronic components are all laid out on the PCB board.

PCB is mainly composed of Copper Cladd laminates (CCL), Pregpre (PP), Copper Foil, Solder Mask, Surface treatment and Silk Screen composition. Nowadays, most PCBs are manufactured using printing technology, so PCB board is also known as printed circuit board.

The function of PCB

Before the emergence of PCB, circuits were composed of point-to-point wiring. The reliability of this method is very low because as the circuit ages, the rupture of the line can lead to the disconnection or short circuit of the line nodes.

Winding technology is a major advancement in circuit technology, which improves the durability and replaceability of the circuit by winding small-diameter wires around the pillars at the connection points.

As the electronics industry develops from vacuum tubes and relays to silicon semiconductors and integrated circuits, the size and price of electronic components are also decreasing. The increasing frequency of electronic products appearing in the consumer sector has prompted manufacturers to seek smaller and more cost-effective solutions. So, PCB was born.

PCB can provide mechanical support for fixing and assembling various electronic components such as integrated circuits, complete wiring and electrical connections or insulation between integrated circuits and other electronic components, provide the required electrical characteristics, provide solder mask patterns for automatic soldering, and provide recognition characters and patterns for component insertion, inspection, and maintenance.

PCB can replace complex wiring and achieve electrical connections between various components in the circuit. It not only simplifies the assembly and soldering work of electronic products, reduces the wiring workload under traditional methods, but also greatly reduces the labor intensity of workers. Moreover, it reduces the overall size of the machine, lowers product costs, and improves the quality and reliability of electronic devices. PCB circuit board have good product consistency and can adopt standardized design, which is beneficial for achieving mechanization and automation in the production process. At the same time, the entire PCB that has been assembled and debugged can be used as an independent spare part, facilitating the exchange and maintenance of the entire product.

At present, PCB have been widely used in the production and manufacturing of electronic products. Almost every electronic device, including headphones, batteries, calculators, communication devices, airplanes, and satellites, requires the use of PCB circuit board for electrical interconnection between integrated circuits and other electronic components.

PCB Printed Circuit Board

PCB design

PCB design is an important part of electronic engineering, which is based on circuit schematics to achieve the functions required by circuit designers. PCB circuit board design mainly refers to layout design, which needs to consider the circuit layout of external connections. Various factors such as optimized layout of internal electronic components, optimized layout of metal connections and vias, electromagnetic protection, and thermal dissipation. Excellent PCB board design can save production costs and achieve good circuit and heat dissipation performance. Simple PCB design can be achieved manually, while complex PCB design requires the use of computer-aided design (CAD).

Common PCB design software includes Protel, Protel DXP, Altium Designer, Cadence SPB, Mentor EE, and EAGLE. These software have their own characteristics and are suitable for different design requirements and complexities. Beginners can choose more user-friendly software such as Cadence SPB to get started.

The PCB design process typically includes steps such as schematic design, electronic component configuration, layout, and wiring. Each step needs to be carefully planned and adjusted to ensure the performance and PCB quality of the final PCB product.

PCB layout refers to placing electronic components in appropriate positions on a circuit board, while wiring connects these components through wires. This process requires consideration of signal integrity and electromagnetic compatibility to avoid interference and malfunctions.

In the PCB design process, a series of design rules need to be followed, including component spacing, wire width, via size, etc., to ensure DFM manufacturability and PCB reliability.

The current high-density PCB design is no longer suitable for through holes, which waste many valuable wiring channels. To solve this contradiction, blind hole and buried hole technologies have emerged. They not only fulfill the role of conductive holes, but also save many wiring channels, making the wiring process more convenient, smooth, and complete. The PCB board design process is a complex process.

In PCB design, PCB layout is an important step in completing product design. It can be said that all the preparatory work is done for it. In the entire PCB design process, the PCB layout design process has the highest limit, the finest skills, and the largest workload.

After the PCB design engineer completes the PCB design, the next step is to make the PCB. How to make PCB? PCB manufacturing is a complex job that consists of many processes.

1. PCB materials: Purchase PCB materials such as PCB copper-clad laminates, copper foils, solder mask ink, screen printing ink, etc. Usually, PCB customers order materials for PCB production, but the PCB Circuit board manufacturer's warehouse does not have this material, so it is necessary to purchase PCB materials, such as some unpopular RF PCB or ceramic PCB materials.

2. PCB copper-clad board cutting: Cut the material provided by the PCB copper-clad board supplier into PNL work boards to facilitate subsequent PCB process operations.

3. Inner layer lamination: The inner layer of circuit board is manufactured by printing copper foil and dielectric layer. In this step, the copper foil layer and the dielectric layer are bonded together through high temperature and pressure to form an inner layer.

4. Inner circuit: Using chemical methods to remove unwanted copper foil through etching, while retaining the designed wires and circuits. This step generates the inner circuit layers of the PCB based on the design.

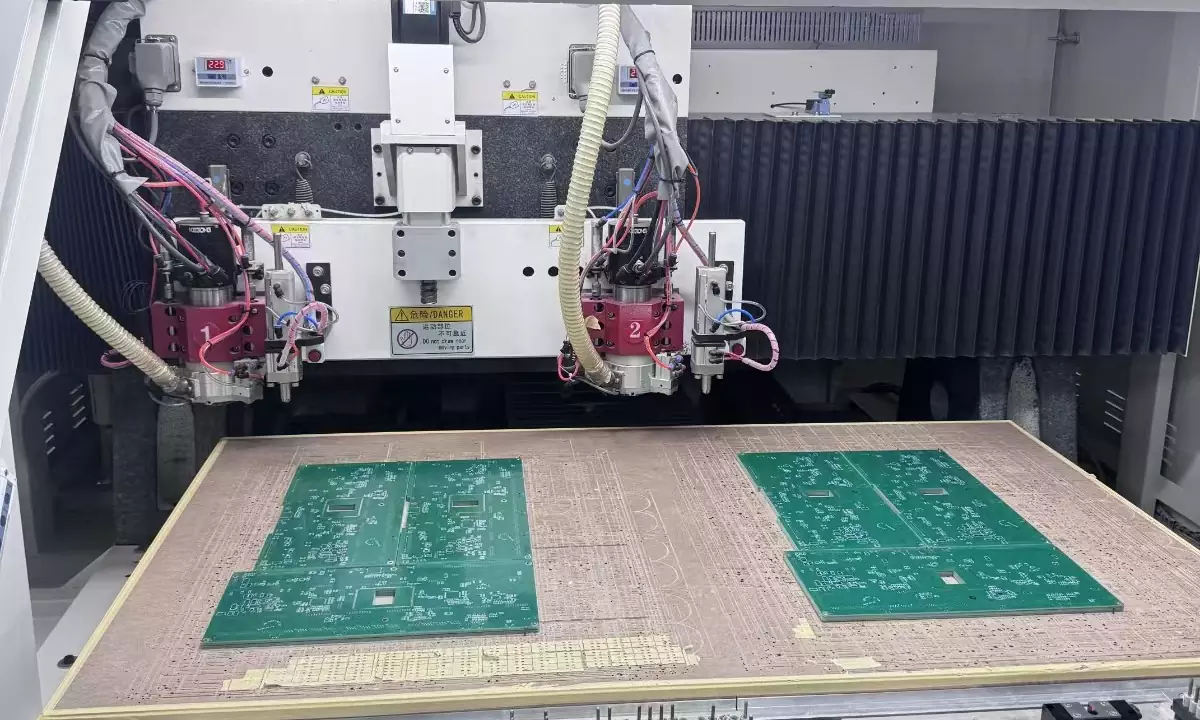

5. PCB drilling: Inter layer connections are usually made by drilling holes at the required locations, which are commonly referred to as through holes. With the increasing precision of circuits, HDI PCB board require the production of PCB buried holes and PCB blind holes.

6. PCB hole metallization: After drilling the PCB, the holes inside the PCB are copper free holes (NPTH). The PNL working board needs to be plated with copper through deposition to lay the copper flat, and then the PCB holes are thickened through PCB electroplating process.

7. Outer circuit: The outer layer of the PCB circuit board is subjected to a graphic treatment similar to the inner layer, and excess copper foil is removed by etching to form the final PCB wire pattern.

8. Solder mask and silk screen printing: Cover the PCB surface with a layer of solder mask ink, and then form the required solder mask area through graphic processing. The silk screen layer is used for printing marks and text.

9. PCB surface treatment: In order to prevent PCB surface oxidation and improve soldering performance, PCB surfaces are usually treated, such as gold plating, tin, ENIG, OSP, immersion silver, immersion gold etc.

10. PCB Cutting: Use a CNC lathe or mold to punch the PNL work board into PCB sizes for delivery to customers, such as 1 pcs of PCB.

11. PCB testing: PCB sample is usually tested for open and short circuits using a flying pin tester. For mass-produced PCB board, specialized PCB testing racks are usually required to achieve higher testing efficiency.

12. FQC quality inspection: After the testing is completed, QC quality personnel conduct visual inspection of the PCB according to IPC quality standards, or use AVI appearance inspection machine for stricter quality inspection. The PCB circuit board can only be packaged if it meets the customer's requirements.

13. Packaging and shipping: Circuit boards are usually sealed and packaged using a PCB vacuum packaging machine before being shipped.

PCB manufacturing

Is there a difference between PCB vs PCBA?

PCB is a Blank PCB or Bare PCB. The PCB board only provides support and electrical connections for electronic components. PCBA includes PCB and its components. PCBA refers to a PCB processing flow, which can also be understood as a finished circuit board. It can only be considered PCBA after all the processes on the PCB board have been completed.

The simple understanding is that PCBA is a finished PCB board, and PCB is a bare PCB board. Let me explain again, what is PCB?

If you have completed the PCB design, you now need PCB manufacturing. How to customize PCB?

iPCB is a professional PCB manufacturer. We have ceramic PCB, aluminum oxide ceramic PCB(AIN PCB), aluminum nitride ceramic PCB, PWB, PCB board, aluminum PCB, copper PCB, high-frequency circuit board, thick copper PCB, impedance PCB board, ultra-thin PCB, FPC, flexible PCB, rigid-flexible PCB, HDI PCB, etc. iPCB has PCB research and development capabilities and can cooperate with customers to develop PCB.

Please send Gerber files and PCB production requirements files to the iPCB email, We will reply to your PCB quotation soon.