We will explain common PCB circuit board materials and their characteristics in detail here.

1. Silicon carbide material

1. High thermal conductivity: Silicon carbide material has high thermal conductivity, which can ensure excellent heat dissipation effect of circuit boards in high temperature environments, providing reliable guarantee for circuit board design in high temperature environments.

2. Excellent high-temperature resistance: Silicon carbide materials have excellent high-temperature resistance, making them useful in fields with extremely demanding temperature requirements such as automotive electronics and aerospace electronics.

3. Low energy consumption advantage: Even under high temperature conditions, silicon carbide materials can still maintain low energy consumption, contributing to the energy-saving operation of electronic equipment.

4. Processing difficulty and cost considerations: However, due to the high hardness of silicon carbide material, it is difficult to process, which also makes it relatively expensive.

2. FR-4 material

1. Wide range of applications: FR-4 material, as one of the most common PCB board materials, is widely used in many fields such as communication equipment, computers, consumer electronics, and automotive electronics.

2. Good insulation properties: FR-4 material has excellent electrical insulation properties, which can effectively isolate the conductive layer and ensure the stable operation of the circuit.

3. High mechanical strength: It has high mechanical strength, can withstand certain mechanical stress, and provides reliable physical support for the circuit board.

4. Good thermal stability: FR-4 material can work stably in high temperature environments and can withstand multiple repeated heat and cold cycles, showing strong environmental adaptability.

5. Better flame retardant properties: Although FR-4 materials have certain flame retardant properties, in some special environments, additional processing may be required to ensure safety.

6. Moderate dielectric constant: The dielectric constant of FR-4 material is about 4.5 - 5.5, which is suitable for general circuit board design and can meet the needs of most electronic devices.

3. Metal materials

1. Excellent electrical conductivity: Metal materials such as aluminum, copper, tungsten, etc. have good electrical conductivity, which can effectively improve the conductivity of the PCB board and ensure rapid signal transmission.

2. Excellent thermal conductivity: Metal materials have excellent thermal conductivity and perform well in high-power electronic devices and applications with high heat dissipation requirements.

3. Remarkable electromagnetic shielding effect: Metal materials can effectively shield electromagnetic fields, reduce electromagnetic interference, and create a good electromagnetic environment for the stable operation of electronic equipment.

4. Cost and shielding treatment: However, the cost of metal materials is higher, which increases the overall manufacturing cost of the PCB board. At the same time, because metal materials easily generate electromagnetic fields, they need to be shielded to prevent interference.

4. Polytetrafluoroethylene (PTFE) material

1. Excellent chemical resistance: PTFE material has good chemical resistance, can resist the erosion of various chemical substances, and can still maintain stable performance in harsh chemical environments.

2. High temperature resistance: PTFE material can work stably in high temperature environments, is suitable for applications in high frequency and high temperature environments, and provides a reliable foundation for high-performance electronic equipment.

3. Advantages of low dielectric constant: PTFE material has a low dielectric constant (about 2.1), which is very suitable for high-speed transmission circuit board design and can meet the needs of high-speed data transmission.

4. Cost considerations: The cost of PTFE materials is relatively high, which also increases the manufacturing cost of PCB boards. The balance between cost and performance needs to be considered during design.

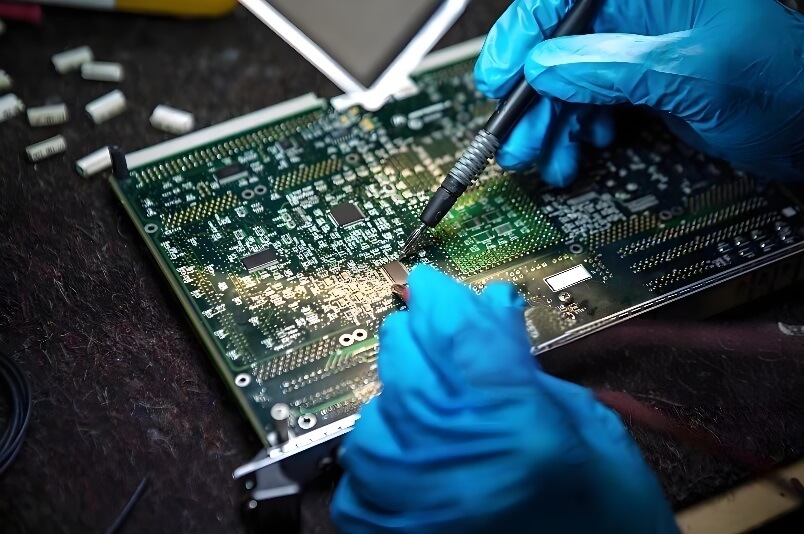

PCB Circuit Board

5. Ceramic substrate

1. Excellent high-temperature resistance: Ceramic substrates have good high-temperature resistance, are particularly suitable for high-frequency and high-power circuits, and can maintain stable electrical performance in high-temperature environments.

2. Low dielectric constant: The ceramic substrate has a low dielectric constant, which is conducive to high-speed signal transmission and provides an ideal solution for high-speed electronic equipment.

3. High mechanical strength: Ceramic substrates have high mechanical strength and can withstand large mechanical stress, ensuring the reliability of electronic equipment.

4. Fragility challenges: However, ceramic substrates are brittle and prone to cracking under mechanical stress, which also brings certain challenges to their application and requires attention during design and use.

6. Phenolic resin

1. Low-cost advantage: Phenolic resin is a low-cost PCB substrate suitable for cost-sensitive applications, providing an affordable option for projects with limited budgets.

2. Good electrical insulation properties: Phenolic resin has good electrical insulation properties, which can effectively isolate the conductive layer and ensure the safe operation of the circuit.

3. Moderate mechanical strength: Phenolic resin has moderate mechanical strength and can withstand certain mechanical stress to meet the needs of general electronic equipment.

4. Poor heat resistance: However, phenolic resin has poor heat resistance and is not suitable for high temperature environments. The specific application scenario needs to be considered when selecting.

7. Glass fiber cloth base material

1. Good thermal stability: The fiberglass cloth substrate has good thermal stability and can work stably in high temperature environments, ensuring the reliability of electronic equipment.

2. Excellent high-frequency performance: The glass fiber cloth substrate has excellent high-frequency performance, is suitable for high-frequency applications, and can meet the needs of high-speed data transmission.

3. High mechanical strength: The fiberglass cloth base material has high mechanical strength and can withstand large mechanical stress, providing support for the stability of electronic equipment.

8. Composite base (CEM series)

1. Excellent comprehensive performance: CEM series materials combine the advantages of different base materials, have excellent comprehensive performance, and can meet the needs of various complex electronic equipment.

2. Diversified choices: The CEM series has a wide variety of materials, and the appropriate model can be selected according to specific needs, providing designers with more room for choice.

3. Moderate cost: CEM series materials are moderately cost-effective, not too expensive, yet provide good performance and are suitable for most PCB board designs.

To sum up, PCB circuit boards are made of a wide variety of materials, and each material has its own unique characteristics and application scenarios. When choosing a PCB material, you need to consider it based on your specific application needs, cost budget, and performance requirements. Only by choosing the appropriate PCB material can the performance, reliability and service life of the circuit board be effectively improved to meet the needs of different electronic devices.