Product Name:FPC connector

Material:PI,PET

Thickness: 1.2mm

Copper thickness: 11OZ

Surface technology: gold plating

Solder mask: White/Green/

Silk screen: White

Minimum line width/spacing: 3mil

Minimum through-hole: 0.3mm

Application:Various electronic product

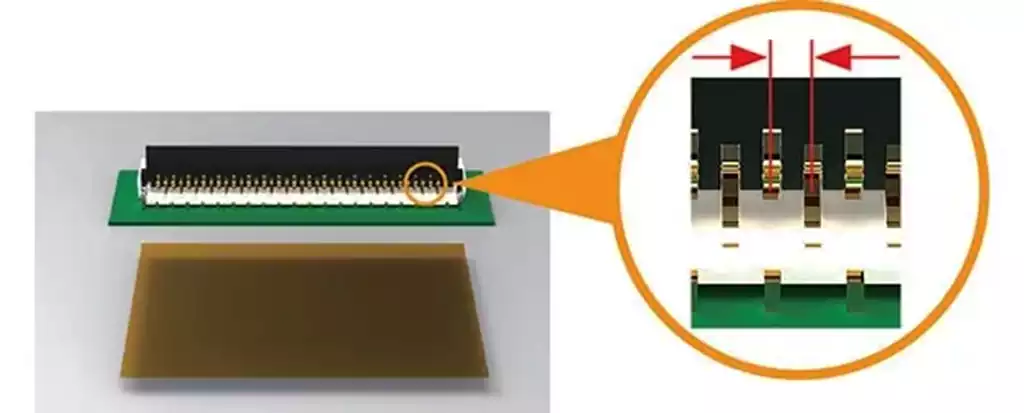

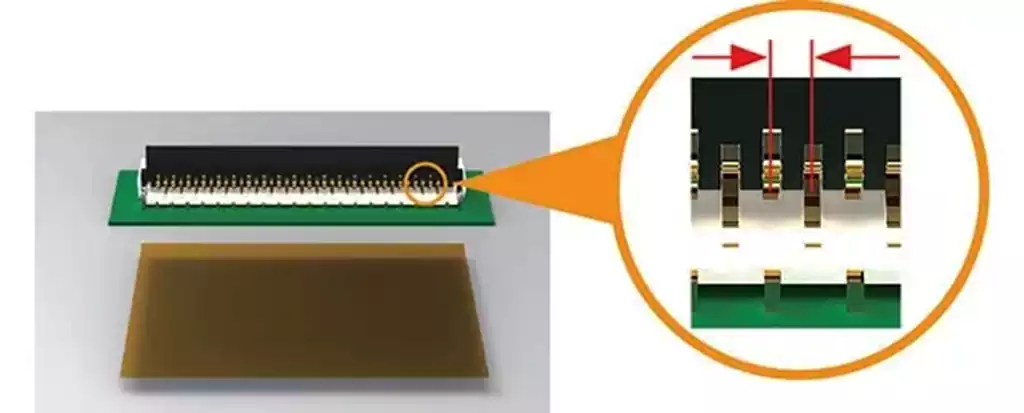

FPC connector is one of a variety of connectors,is often used in the PCB board to a connector,and in different PCB boards,it should be based on the corresponding electronic equipment requirements to select the corresponding size of the flexible connector.

FPC connector works through a series of contact points,by the terminals and the corresponding screw connection.One or more terminals,each terminal has a screw connection,one of the screws connected to the terminal, another screw connected to the corresponding print circuit board.When the two screws are connected together,a complete circuit is formed between the contacts on the circuit board on the terminal block, thus achieving the purpose of connecting the circuit board.

The main components of FPC connector

1.Rubber core:The main function of the rubber core is to protect the terminals, provide guidance when insulating the connection, and enhance the strength of the mechanism.It is usually manufactured using injection moulding process,the main material is PA9T.

2.Tongue:The tongue is used to crimp the cable insulation, provide guidance when connecting, and enhance the strength of the mechanism.The tongue is also manufactured by injection moulding process and the main materials are PA10T and PPS.

3.Terminals:Terminals are conductors of electronic signals and are responsible for transmitting electronic signals.The manufacturing process of terminals includes stamping and plating (gold-plated or tin-plated to improve solderability),the material is usually phosphor bronze C5191.

4.Solder lugs:Solder lugs are used to position, fix and add strength to components.The manufacturing process of the solder pad also includes stamping and plating, the material is bronze C2680.

FPC connectors, i.e. Flexible connectors, are widely used in many fields due to their flexible,lightweight and high precision features.The following are the main application areas of Flexible connectors:

1.Consumer electronics field: In smart phones, tablet PCs, laptops and other consumer electronics products,flexible connector is used to connect motherboards and modules such as displays,cameras, touch screens, etc., and play a role in transmitting signals and data. Its miniaturisation and thin design make it not occupy too much space in these devices.

2.Automotive electronics:FPC connectors are used in automotive electronic systems to connect instrument panels,navigation systems,audio systems and other equipment to transmit various signals and data.They are shock-resistant, high temperature-resistant,corrosion-resistant,etc.,which ensures the reliability and stability of the connection.

3.Medical device field: In medical devices,flexible circuit board connectors are used to connect various sensors,controllers,monitors and other devices to transmit various signals and data. Its flexibility and bendability allow it to be used in contact with human organs, improving the precision and portability of medical devices.

4.Industrial control field: flexible connector is used in industrial control equipment to connect various sensors,actuators and control units to ensure the accuracy and reliability of signal transmission.They play an important role in automated production lines and robotics.

5.Aerospace: In aerospace equipment,it is used to connect complex electronic systems such as navigation,communication and control systems.They are able to maintain performance in extreme environments and meet the high requirements of aerospace equipment.

6.Smart home field: With the development of smart home technology,flexible connector is used in smart home appliances,home security systems and smart lighting systems to provide flexible connection solutions.

7.Mobile device field:flexible connector is widely used in the field of mobile devices,such as smart phones and tablet PCs.They connect the screen,camera, battery,buttons and other components to ensure the normal operation of the device.

8.Other fields:flexible connector is also used in the military,communications,energy and multimedia equipment, etc.,to provide flexible and reliable connection solutions.The miniaturisation of FPC connectors,the ability of high-frequency signal transmission, and the adaptability of the SMT process make them more and more important in modern electronic equipment.As technology advances,the application areas of flexible connector is expected to continue to expand.

FPC connector,as a type of flexible pcb,is widely used in smartphones,tablet PCs,wearable devices, and other fields due to their thin, lightweight,and bendable characteristics.As the market for these smart devices continues to grow,the market demand for flexible connectors is also expanding.

In addition,with the promotion of 5G technology and the development of new energy vehicles,the application of FPC connectors in the field of communications and automotive electronics is also increasing,further boosting the growth of the market. However, the market competition is also becoming increasingly fierce.A research report on the competitive environment and brand market share of China's flexible connector industry shows that there are many companies in the industry and the competitive landscape is complex. Enterprises need to continuously innovate and improve product quality and technology in order to occupy a favourable position in the fierce market competition.

Product Name:FPC connector

Material:PI,PET

Thickness: 1.2mm

Copper thickness: 11OZ

Surface technology: gold plating

Solder mask: White/Green/

Silk screen: White

Minimum line width/spacing: 3mil

Minimum through-hole: 0.3mm

Application:Various electronic product

iPCB Corporation provides support for PCB Prototype and Electronic Manufacturing. You can request consultation or quotation for PCB, PCBA and ODM here, please contact email: sales@ipcb.com

We will respond very quickly.