Most of the electronics we use daily rely on printed circuit boards (PCBs) as the core hardware, connecting passive components and integrated circuits to form intricate circuitry. In this article, we explore the main distinctions between PCBA and PCB.

Introduction

This article explores the critical role of printed circuit boards (PCBs) and printed circuit board assemblies (PCBAs) in modern electronics. It highlights the importance of understanding their differences for

engineers, designers, and manufacturers to make informed decisions in product development. The article covers the definitions, functions, types, manufacturing processes, and key differences of both PCBs and PCBAs, emphasizing their applications and providing insights for optimizing electronic projects.

PCB: Printed Circuit Board

Definition and Function of PCB

A Printed Circuit Board (PCB) is a thin, insulating board, often made from fiberglass or epoxy resin, with copper pathways that connect electronic components like resistors and capacitors. The primary function of a PCB is to provide a stable platform for mounting and interconnecting these components, reducing wiring complexity, enhancing reliability, and aiding troubleshooting. PCBs also offer mechanical support, ensuring components stay aligned, especially in high-vibration environments. Performance factors include trace width, insulating material, and solder joint quality.

Types of PCBs

Single-sided PCBs: Simple, cost-effective, with traces on one side, used in low-complexity circuits.

Double-sided PCBs: Traces on both sides, offering more flexibility for higher complexity, used in automotive and industrial electronics.

Multilayer PCBs: Multiple layers for high-density, complex designs, used in high-performance electronics like computers and smartphones.

Design: The layout of the PCB is created using CAD software, including component placement and trace routing. This design is converted into manufacturing files.

Fabrication: A substrate (typically FR-4) is coated with copper, etched for traces, and drilled for connections. Layers are laminated for multilayer boards, and solder masks and silkscreen layers are applied.

Assembly: Components are mounted and soldered using through-hole or surface-mount technology (SMT). The board is tested for functionality before integration into the final product.

Each stage of the process requires precision to ensure the PCB's reliability and performance.

PCB

PCBA: Printed Circuit Board Assembly

Definition and Function of PCBA

A Printed Circuit Board Assembly (PCBA) refers to a PCB that has all the required electronic components mounted and soldered onto it, creating a fully functional circuit. The primary role of a PCBA is to enable the components to work together, providing electrical interconnection and routing signals between components. It ensures stable electrical performance through features like ground planes, voltage planes, and impedance control, making it essential in the production of electronic devices.

Types of PCBAs

Through-Hole Assembled PCBAs: Components with leads inserted into holes for strong mechanical connections. Ideal for older devices and power electronics, but less suitable for miniaturized designs.

Surface-Mount Assembled PCBAs: Components mounted directly on the PCB using reflow soldering, allowing for high component density and compact designs. Common in modern electronics like smartphones and IoT devices.

Mixed-Technology PCBAs: Combining both through-hole and surface-mount components, used in industrial, automotive, and medical applications where both component types are needed.

PCBA Manufacturing Process

PCB Fabrication: Creating the physical PCB based on design files, including etching copper traces, drilling holes, and applying solder mask and silkscreen layers.

Component Procurement: Sourcing components based on design requirements, including performance, cost, and form factor.

Assembly: Mounting and soldering components onto the PCB using techniques such as:

Stencil Printing: Applying solder paste for surface-mount components.

Component Placement: Automated machines place components onto the PCB.

Reflow Soldering: Heating the PCB in a reflow oven to create solder joints for surface-mount components.

Soldering for Through-Hole Components: Using wave or selective soldering.

Inspection and Testing: After assembly, the PCBA undergoes inspection for defects and testing for functionality using methods like visual inspection, automated optical inspection (AOI), X-ray, in-circuit testing (ICT), and functional testing.

Understanding the PCBA manufacturing stages helps engineers optimize performance, cost, and manufacturability, ensuring high-quality and reliable final electronic devices.

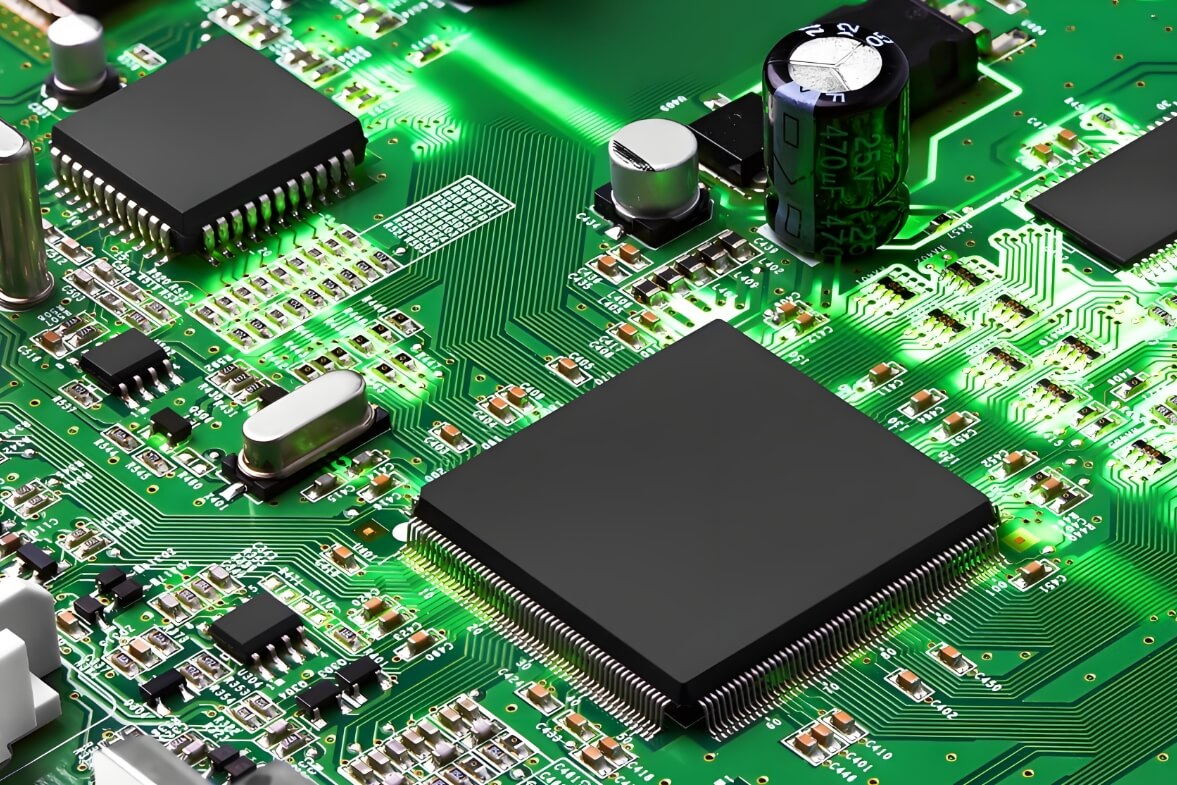

PCBA

Key Differences between PCB vs. PCBA

Manufacturing Process

PCB Manufacturing: Involves designing the layout, fabricating the physical board, and applying solder mask and silkscreen layers. The result is a bare PCB with conductive traces and holes, but without components.

PCBA Manufacturing: Builds upon PCB manufacturing by adding the assembly process, which includes component procurement, placement, soldering, and thorough inspection and testing to create a fully functional circuit.

Components and Complexity

PCB: Composed of an insulating substrate, conductive traces, and holes for components, with complexity determined by layout, layer count, and interconnection density. It does not contain any electronic components.

PCBA: Includes all necessary electronic components (e.g., resistors, capacitors, ICs) mounted and soldered onto the PCB, making it a complete, functional circuit. Its complexity is influenced by both the PCB design and component arrangement.

Cost and Time Considerations

PCB: Generally less expensive and faster to produce, as it involves fewer steps (fabrication only). Costs rise with design complexity and board layers.

PCBA: More expensive and time-consuming due to additional steps like component procurement, assembly, and testing. The overall cost is impacted by component type, quantity, and assembly techniques.

Key Differences in Summary:

| Feature | PCB | PCBA |

|---|---|---|

| Definition | A board with conductive layers but no components. | A PCB with all components mounted and soldered. |

| Functionality | Provides a platform for component mounting. | Offers a complete, functional circuit. |

| Manufacturing | Involves design, fabrication, and testing. | Includes component procurement, assembly, and testing. |

| Complexity | Determined by layout, layers, and interconnections. | Influenced by PCB design and component arrangement. |

| Cost & Time | Less expensive and quicker to produce. | More complex, costlier, and time-consuming. |

| Flexibility | Rigid, flexible, or rigid-flex designs. | Can be based on any type of PCB. |

| Assembly Techniques | Not applicable. | Involves through-hole soldering, SMT, BGA, etc. |

| Applications | Found in nearly all electronic devices. | Found in fully functional electronic devices. |

| Durability | Depends on material and design. | Influenced by PCB quality and component reliability. |

Choosing between PCB and PCBA depends on various factors, including cost, time, complexity, and the project’s functional requirements. Understanding these differences helps engineers and manufacturers make informed decisions that optimize performance, reliability, and cost-efficiency in the development of electronic devices.