What is PCBA?

PCBA meaning is an electronic control board assembled with blank PCB and PCBA components through SMT (Surface Mounted Technology) and DIP. PCBA stands for Printed Circuit Board Assembly, which refers to the entire process of SMT mounting or DIP insertion of a blank PCB board, abbreviated as PCBA. In some countries, the standard writing is PCB'A.

PCBA is composed of PCB printed circuit board, electronic components, and solder. The PCB provides support for electronic components, which realize the electrical functions of the PCBA. Solder is a solder alloy that connects electronic components to the PCB.

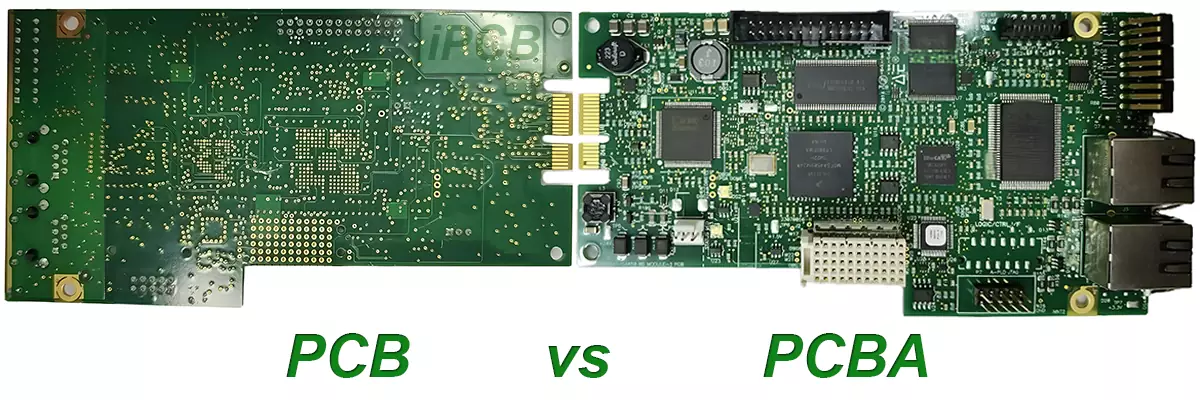

What is difference between PCB and PCBA?

In the electronic manufacturing industry, PCB and PCBA are two commonly mentioned terms. Although there is only a one character difference between them, there are significant differences in function and structure.

PCB is a printed circuit board, which supports electronic components and provides circuit connections for electronic components. It uses copper-clad laminates as the substrate, prints circuit patterns on the substrate through printing technology, and then forms conductive circuits through processes such as etching and electroplating.

PCB, as the carrier and connector of PCBA components, mainly plays a supporting and conductive role. It does not have any electronic functions itself, but only provides a stable working environment and electrical connection for PCBA components.

PCBA is the assembly of PCBA components onto a PCB through processes such as SMT (Surface Mount Technology) or DIP (Plug in Package Technology), forming a fully functional electronic module. Therefore, PCBA not only contains all the elements of PCB, but also includes additional PCBA components assembled on it.

PCBA is a fully functional electronic module. It not only includes all the functions of the PCB, but also achieves specific electronic functions through PCBA components assembled on the PCB. For example, a wireless charger PCBA includes key PCBA components such as processor, memory, and storage, as well as circuits that implement product functions.

Differences between PCB and PCBA

1. Assembly status: PCBA assembled, PCB not assembled

2. Function: PCBA has functionality, PCB is only a connection frame3. Complexity: PCBA is more complex

4. Cost: PCBA is more expensive

5. Purpose: PCBA is used for electronic devices, PCB is used for manufacturing PCBA

The short explanation is that PCBA is an assembled PCB, while PCB is a bare PCB board. Each stage of PCB and PCBA requires strict quality control to ensure the performance and reliability of the final product.

What is PCBA manufacturing? PCBA assembly manufacturing process

1. Blank PCB board loading (automatic board loading)

The first step in PCBA manufacturing is to arrange the blank PCB board neatly and place them on the material rack. The automatic loading machine will automatically feed the PCBA board piece by piece into the printing machine of the SMT assembly line through the docking station.

2. Printing solder paste (solder paste printing machine)

The first step in the SMT PCBA process for PCB is to print solder paste, which will be printed on the solder pads of the components to be soldered on the PCB. These solder pastes will melt and solder electronic components onto the circuit board during high-temperature reflow soldering.

3. Solder Paste Inspection Machine (SPI)

The quality of solder paste printing (such as excessive or insufficient solder, and whether the solder paste is viscous) is related to the quality of the subsequent component soldering. Therefore, some PCBA line will first use optical instruments to check the quality of solder paste printing after solder paste printing in order to ensure stable quality. If there are poorly printed PCBA boards, they will be removed and the solder paste on top will be washed off before reprinting, or excess solder paste will be removed by repair.

4. High speed SMT machine

High speed SMT machines first attach some smaller electronic components (such as small resistors, capacitors, inductors) 0201, 0402 and other components to the circuit board. These parts will be slightly stuck by the solder paste just printed on the circuit board, so the SMT speed is very fast and the components on the PCBA board will not scatter. However, large electronic components are not suitable for high-speed machine pasting, as it will drag down the speed of pasting small parts that are too fast.

5. Multi functional SMT machine

Multi functional surface mount machines manufacture electronic components with relatively large volumes, such as BGA, IC, connectors, SOP, etc. These components require accurate positioning, and alignment is very important. Before surface mounting, a camera is used to confirm the position of the parts, so the speed is relatively slow. Due to their size, components may not necessarily have tape packaging, and some may be packaged in trays or tubes. If SMT machines are to eat trays or tubular packaging materials, an additional machine must be configured. So the top of these electronic components must have a flat surface left for the suction nozzle of the cutting machine to suck up the parts. However, some electronic components do not have a flat surface left for these machines. In this case, special suction nozzles need to be customized for these irregular parts, or a layer of flat tape needs to be added to the parts, or flat caps need to be worn.

6. Reflow soldering

Reflow soldering melts solder paste and places it on the pins of the component and the circuit board. The curve of temperature rise and fall affects the quality of the entire circuit board soldering. Generally, reflow ovens set preheating zones, wetting zones, reflow zones, and cooling zones to achieve the best soldering effect. The maximum temperature in the reflow oven should not exceed 250 ℃, otherwise many parts may deform or melt due to the inability to withstand such high temperatures.

7. PCBA inspection - AOI

Not every PCBA factory necessarily has an optical inspection machine (AOI). The purpose of AOI is to inspect parts for tombstones, side standing, missing parts, displacement, bridging, empty soldering, etc. However, the solder under the components cannot determine whether there is false soldering, BGA solderability, resistance value, capacitance value, inductance value and other part quality. Therefore, it has not been able to completely replace ICT so far. So if only AOI is used to replace ICT, there are still some risks in terms of quality.

8. Visual inspection of finished products

Regardless of whether an AOI process is established or not, a general PCBA manufacturing production line still sets up a visual inspection area to check for any defects after the circuit board assembly is completed. If there is an AOI, it can reduce the number of visual inspection personnel because it still needs to inspect some areas that cannot be detected by AOI.

9. What is PCBA test?

The main purpose of using ICT settings for PCBA testing is to test whether there are open or short circuits in the components and circuits on the circuit board. In addition, it can also measure the basic characteristics of most components, such as resistance, capacitance, and inductance values, to determine whether these components have been damaged, faulty, or missing after passing through a high-temperature reflow oven.

10. PCBA sub board

Generally, circuit board is assembled to increase the efficiency of PCBA manufacturing. There are usually assam PCBA, and after all PCBA manufacturing is completed, they need to be cut into PCBA single board. Some circuit boards that only have single PCBA board also need to cut off some excess board edges.

PCBA manufacturing

How to order PCBA?

iPCB is a PCBA manufacturer in China, providing one-stop services from PCB design to PCBA manufacturing for global customers. iPCB relies on years of experience in PCB and PCBA manufacturing, with rigorous design management processes, quality control standards, and QA control systems. The services and products involve fields such as network communication, industrial control, medical, aerospace, servers, automotive electronics, consumer electronics, portable devices, and mobile phone design.

If you need a PCBA supplier to provide you with PCBA manufacturing services, please send the Gerber file and BOM to iPCB, We will reply to you with a PCBA quotation soon.