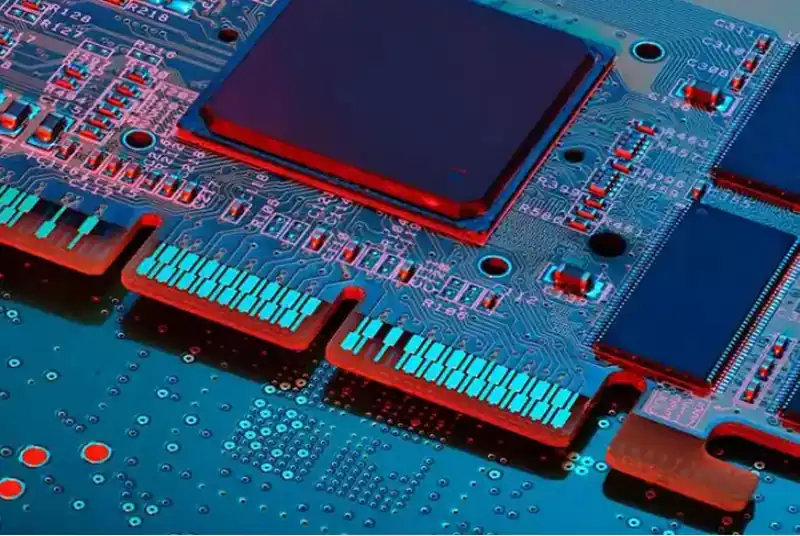

PCBA refers to printed circuit board assembly technology,which assembles components,integrated circuits and other assemblies onto completed printed circuit boards to form a complete circuit system.PCBA consists of two main parts:printed circuit boards and assembly components.Among them,the printed circuit board is a basic material used to connect and support various electronic components,while the assembly components include a variety of components that are soldered on the printed circuit board.

PCBA Manufacturing Process:

SMT Mounting:As the first and crucial part of PCBA manufacturing,the SMT mounting process involves the precise and accurate placement of various SMD (Surface Mount Device) components such as resistors,capacitors,diodes,transistors and integrated circuits on the printed circuit board.This step is highly dependent on automated production,which significantly improves productivity and product quality.

DIP Component Insertion:DIP (Dual In-line Package) component insertion refers to the process of manually installing components that need to be inserted into the circuit board through perforated holes, such as LEDs,buttons,and sockets.Compared to SMT mounting,DIP component insertion is relatively slow,as it relies more on manual operation.

AOI Inspection:AOI (Automated Optical Inspection) is an advanced automated inspection technology designed to check the quality of PCBA soldering and the accuracy of component placement.The application of AOI inspection greatly enhances the consistency and reliability of the product and ensures the quality of production.

Performance testing:Performance testing is the last hurdle in the PCBA manufacturing process,which is mainly used to verify whether the function of the PCBA circuit system meets the design requirements.In this stage,the need to use professional test equipment for PCBA comprehensive testing to ensure that product performance up to standard.

Product Packaging:As the PCBA manufacturing the final work,product packaging is critical.This step requires the selection of appropriate packaging materials, such as foam, cardboard boxes, plastic bags, etc., in order to properly protect the PCBA from damage,to ensure that the product is safe in the transport and storage process.

The core steps of PCBA processing flow:

Step 1:Solder paste application

A squeegee is used to push the solder paste on the surface of the stencil until the paste touches the aperture area of the stencil. At this point, the pressure exerted by the squeegee forces the paste through the stencil apertures and deposits it onto the board.

Step 2:Adhesive application (optional process)

For boards assembled on both sides,adhesives are used to hold the components in place in order to prevent the bottom components from falling off during wave soldering or the large IC components from melting and falling off during double sided reflow soldering.

Step 3:Placement of components

This step picks up the surface-mounted components from the feeder by means of an automated placement machine and places them precisely on the printed circuit board.

Step 4:Inspection before and after soldering

Before the components go into the reflow soldering,the placement condition and position of the components need to be carefully checked for any offset.

Step 5:Reflow Soldering

The component is placed on the solder and the reflow soldering process using thermal convection technology melts the solder on the pads to make the mechanical and electrical connection between the component leads and the pads.

Step 6:Insertion of through-hole components

For through-hole inserted components and some can not be placed by the machine surface mounted components (such as cartridge electrolytic capacitors,connectors, pushbutton switches and metal-terminated electrode components, etc.),need to be manually or automatically inserted.

Step 7:Wave soldering

Wave soldering is mainly used for soldering through hole cartridge components.

Step 8:Cleaning

Step 9:Repair work (off line process)

This step is designed to cost effectively repair defective solder joints or replace defective components.

Step 10:Electrical Performance Testing

Electrical performance testing covers in line testing and functional testing.

PCBA Application Scenario

Because PCBA has the advantages of small size,low power consumption,high reliability,etc.,it is widely used in electronic products.Here is an introduction to the main application of PCBA scenes.

1.Smart home smart home refers to a variety of intelligent devices and sensors to achieve home automation management system.In this system,PCBA plays a vital role, it can control the lights, temperature, access control and other various devices.

2.Industrial automation industrial automation refers to the system of industrial production automation through a variety of intelligent devices and sensors. In this system, PCBA can control robots, conveyor belts, cylinders and other various devices.

3.Security monitoring security monitoring refers to a variety of cameras and sensors to achieve security monitoring system.In this system, PCBA can control various devices such as cameras and alarms.

4.Medical EquipmentMedical equipment refers to a variety of devices used to diagnose and treat diseases. In these devices,PCBA can control various devices such as sphygmomanometers, electrocardiographs, ventilators, and so on.

PCBA technology with its unique advantages is widely used in smart home,industrial automation, security monitoring and medical equipment and other fields, become a key force to promote the development of modern technology,and continue to play an important role in the future of technological innovation.