Product Name: RF Microwave PCB

Material: RF circuit materials

Quality standard: IPC 6012

Rogers PCB material Dk: 2.2-16

Material composition: Ceramic, Teflon,

Layer: 1L - 2L - multilayer PCB

Thickness: 0.1mm - 12mm

Copper thickness: 0.5oz - 6oz

Surface technology: Silver, Gold,

Application: RF microwave application

The operating frequency of RF microwave PCB ranges from 30 kHz to 100 GHz, and it is an important component of wireless communication, radar, broadcasting systems, and other high-frequency circuits. RF microwave circuit boards have special requirements in material selection, design layout, and manufacturing processes to ensure efficient signal transmission and reduce signal loss and interference.

RF microwave PCB material selection: High frequency microwave circuit boards typically use materials with low loss, low dielectric constant (Dk), and low dielectric loss factor (Df), such as high-performance materials like PTFE (polytetrafluoroethylene) and Rogers PCB. These materials can effectively reduce energy loss and delay during signal transmission, ensuring signal integrity.

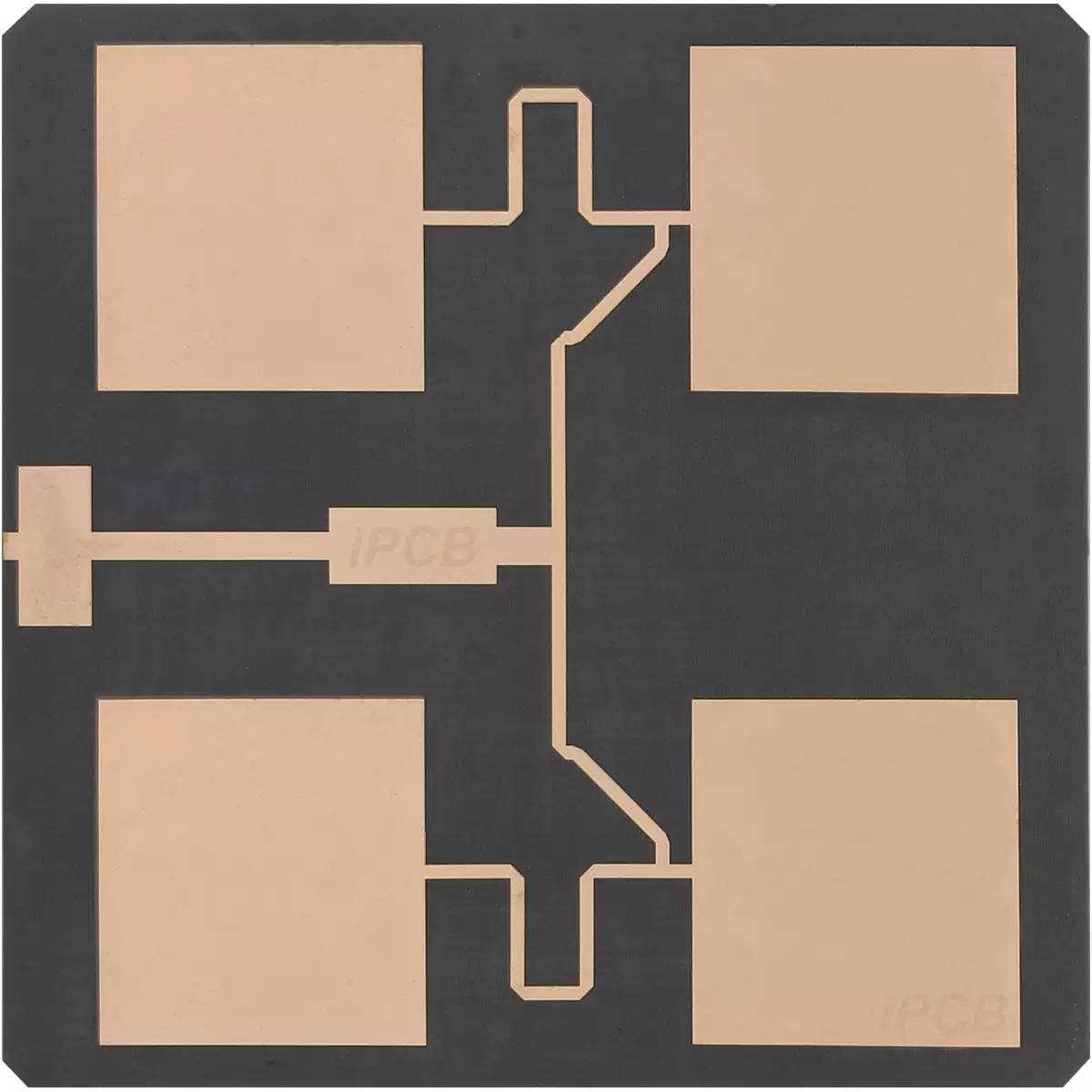

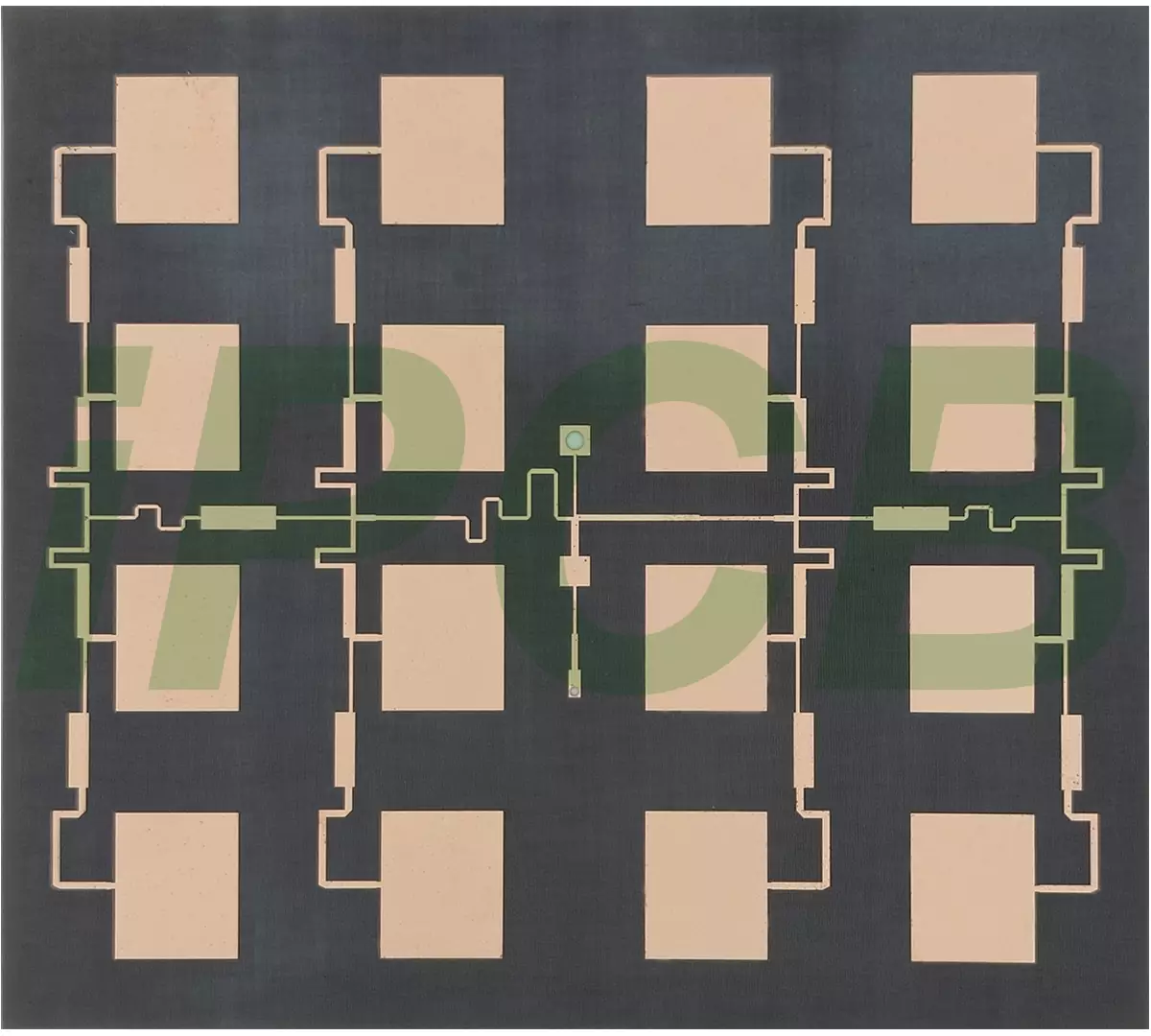

RF microwave circuit layout: At high frequencies, the mutual influence (crosstalk) between signal lines and electromagnetic radiation become key challenges in design. Therefore, the design of high-frequency microwave circuit boards requires strict control of line width, line spacing, number and position of vias, and the use of specific transmission line technologies (such as microstrip lines and strip lines) to control impedance matching and reduce reflection and distortion.

Grounding and shielding of RF microwave circuits: Good grounding design and electromagnetic shielding are key to ensuring the purity of high-frequency signals. High frequency microwave circuit boards often adopt measures such as multi-layer grounding layers and grounding shielding covers to isolate external interference and provide signal return paths, ensuring signal quality.

Manufacturing of RF microwave PCB: The manufacturing of high-frequency microwave circuit board requires extremely high precision, including fine line etching, strict tolerance control, and special coating treatment to meet the needs of high-frequency signal transmission.

The function of RF microwave PCB

Communication system: In the fields of satellite communication, 5G/6G mobile communication, radar systems, etc., high-frequency microwave circuit boards are the core components for achieving high-speed data transmission and precise signal processing.

Aerospace: In the navigation, communication, and radar detection systems of aerospace vehicles, high-frequency microwave circuit boards have become an indispensable part due to their excellent performance.

Medical equipment: In high-end medical imaging devices such as MRI and CT scanners, high-frequency microwave technology is used to generate high-resolution images, which is crucial for diagnostic accuracy.

Military equipment: High frequency microwave circuit boards are widely used in various electronic countermeasures, intelligence gathering, and weapon guidance systems.

Radar technology: High frequency microwave circuit boards and substrates are widely used in signal processing units, transmission and reception modules in radar systems. By optimizing the design of circuit boards and substrates, the sensitivity and resolution of radar systems can be improved, achieving more accurate target detection.

Microwave antenna: High frequency microwave substrate is a key component in building microwave antenna systems. They can achieve the transmission, demodulation, and radiation of microwave signals, improving the receiving and transmitting performance of antenna systems.

RF microwave PCB

Characteristics of RF Microwave PCB

1. DK should be small and stable enough, usually the smaller the better. A high DK may cause signal transmission delay

2. DF needs to be small, mainly affecting the quality of signal transmission. The smaller the direction finder, the smaller the signal, resulting in waste

3. The thermal expansion rate should be as similar as possible to the copper foil, as the difference can cause the copper foil to separate during cold and hot changes

4. The absorption rate of water must be low and high in humid environments, as the absorption rate of water can affect DK and DF

5. Good heat resistance, chemical resistance, impact resistance, and peel resistance are required

RF microwave PCB is an indispensable component in modern electronic devices, especially in fields such as communication, aerospace, military, and medical. With the advancement of technology, the application and impact of high-frequency PCBs will become more significant in the future. In the future PCB board and electronics industry, it will play a more critical role, and technological innovation and microwave PCB material research and development will be key factors driving the industry's development.

Product Name: RF Microwave PCB

Material: RF circuit materials

Quality standard: IPC 6012

Rogers PCB material Dk: 2.2-16

Material composition: Ceramic, Teflon,

Layer: 1L - 2L - multilayer PCB

Thickness: 0.1mm - 12mm

Copper thickness: 0.5oz - 6oz

Surface technology: Silver, Gold,

Application: RF microwave application

iPCB Corporation provides support for PCB Prototype and Electronic Manufacturing. You can request consultation or quotation for PCB, PCBA and ODM here, please contact email: sales@ipcb.com

We will respond very quickly.