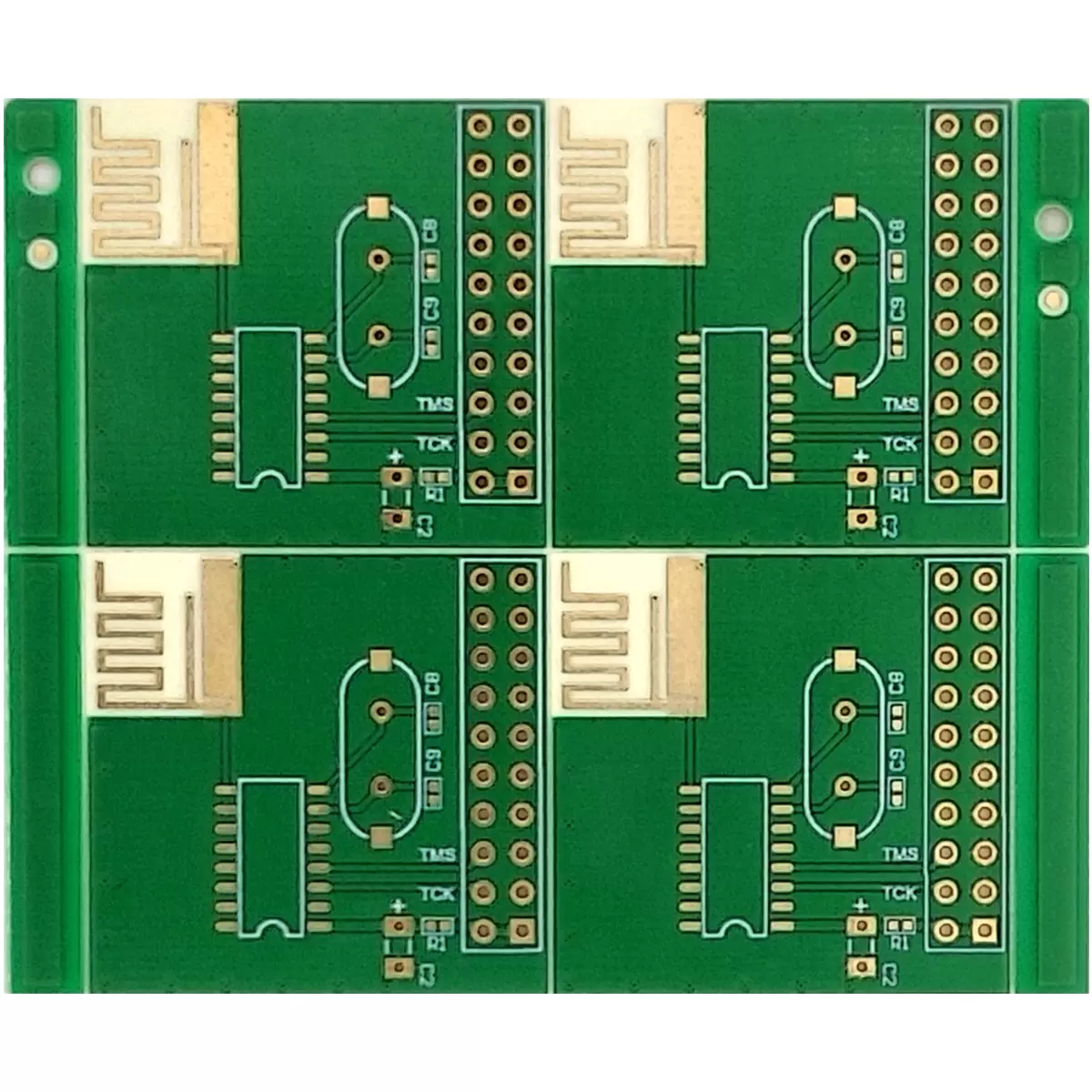

Product Name: FR4 + RO4003C PCB

Material: Rogers RO4003C

Quality standard: IPC 6012

Rogers RO4003C Dk: 3.38

Rogers RO4003C Df: 0.0027

Material composition: Ceramics+Hydrocarbons

Layer: 1L - multilayer PCB

Thickness: 8mil - 60mil

Copper thickness: 1oz

Surface technology: Silver, Gold

Application: Communication, Instruments

Rogers RO4003C PCB is a proprietary hydrocarbon composite material reinforced with glass cloth and filled with ceramics, which combines the electrical properties of PTFE/glass cloth with the processability of epoxy resin/glass.

The RO4003C PCB has two different configurations, using 1080 and 1674 different glass cloths. All configurations have the same electrical performance specifications. The RO4003C PCB has undergone strict process control, and the material has a stable and consistent dielectric constant (Dk) and low loss characteristics. The unique mechanical properties of RO4003C make it the same as standard epoxy resin/glass processing technology, while the cost is much lower than traditional microwave laminates. Unlike PTFE microwave materials, RO4003C does not require special through-hole treatment or operating procedures.

RO4003C PCB has not been brominated and does not comply with UL 94 V-0 standard. For applications or designs that require UL 94 V-0 flame retardant rating, the RO4835 PCB and RO4350B PCB can meet this requirement.

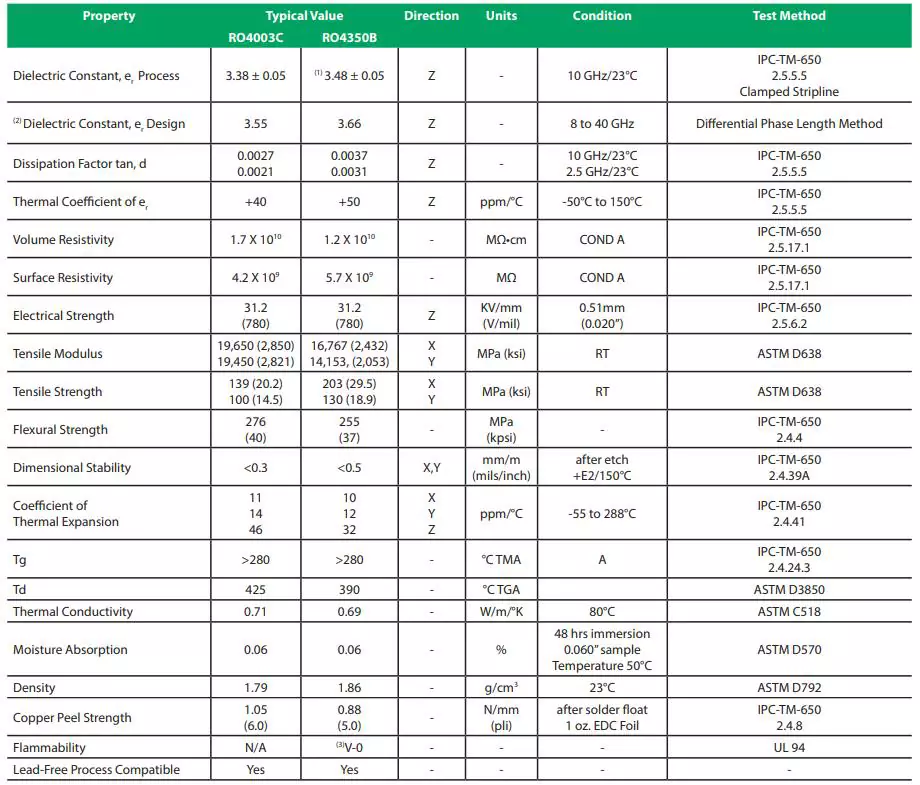

Rogers RO4003C PCB features: Dielectric constant (DK): 3.38 ± 0.05, Loss factor (DF): 0.0027, Z-axis thermal expansion coefficient 46 ppm/° C

Rogers RO4003C PCB thickness: 0.203mm, 0.305mm, 0.406mm, 0.508mm, 0.813mm, 1.524mm

Rogers RO4003C PCB size: 12*18inch(305*457mm), 18*24inch(457*610mm), 24*36inch(610*915mm), 36*48(915*1219mm)

Advantages of Rogers RO4003C PCB

Very suitable for multi-layer board (MLB) structure

Processing technology similar to FR-4, with lower cost

Designed for performance sensitive high-capacity applications

High cost-effectiveness

Rogers RO4003C PCB

1. Excellent electrical performance: The electrical performance of RO4003C high-frequency PCB is very close to that of PTFE/glass cloth material, with stable dielectric constant and low dielectric loss, which has significant advantages in high-frequency applications. Its dielectric constant fluctuates with temperature almost the lowest among similar materials, and it is also quite stable over a wide frequency range.

2. Excellent processing performance: The processability of the RO4003C high-frequency PCB is similar to that of epoxy resin/glass cloth materials, and standard processing techniques for epoxy resin/glass cloth can be used, allowing RF engineers to easily design circuits such as network matching and impedance control of transmission lines.

3. High cost-effectiveness: The price of RO4003C high-frequency PCB is much lower than that of traditional microwave materials, and there is no need for special through-hole pre-treatment or operation procedures, so it has strong price competitiveness.

4. Stable mechanical performance: The RO4003C high-frequency PCB has excellent mechanical performance, with a thermal expansion coefficient similar to copper, providing excellent dimensional stability, which is particularly important for multi-layer circuit design. Even in strict thermal shock applications, the RO4003C PCB can ensure the quality of the through holes inside the board.

Rogers RO4003C PCB Application

RO4003C PCB is suitable for high reliability applications such as aerospace, high-speed PCB, microwave PCB, RF circuit board, etc. In addition, due to its unique mechanical properties, it can be processed using standard epoxy resin/glass cloth processing techniques at a much lower cost than traditional microwave laminates.

RO4003C PCB is a widely used board in the microwave field, with X/Y/Z axial thermal expansion coefficients of 11/14/46 (ppm/℃), which are similar to alumina ceramics. After bonding, the two have good mechanical strength. RO4003C has a low dielectric loss (tan δ of about 0.0024), a dielectric constant that does not vary significantly with temperature and frequency, and a water absorption rate of only 0.04%. These properties ensure that it can be applied to the millimeter wave frequency band.

The RO4003C PCB can be used for designs at frequencies of 26GHz or even higher. Based on a 20mil thickness, ED copper foil, and RO4003C PCB, a 50ohm microstrip line without any surface treatment has a loss characteristic of 0.55dB/inchat 26GHz. Of course, if better performance materials are needed, on the one hand, we can consider using LOPRO copper RO4003C LoPro, and on the other hand, we can also consider using other materials such as RO3035 material and TC350 material, whose Dk is around 3.5.

Product Name: FR4 + RO4003C PCB

Material: Rogers RO4003C

Quality standard: IPC 6012

Rogers RO4003C Dk: 3.38

Rogers RO4003C Df: 0.0027

Material composition: Ceramics+Hydrocarbons

Layer: 1L - multilayer PCB

Thickness: 8mil - 60mil

Copper thickness: 1oz

Surface technology: Silver, Gold

Application: Communication, Instruments

iPCB Corporation provides support for PCB Prototype and Electronic Manufacturing. You can request consultation or quotation for PCB, PCBA and ODM here, please contact email: sales@ipcb.com

We will respond very quickly.