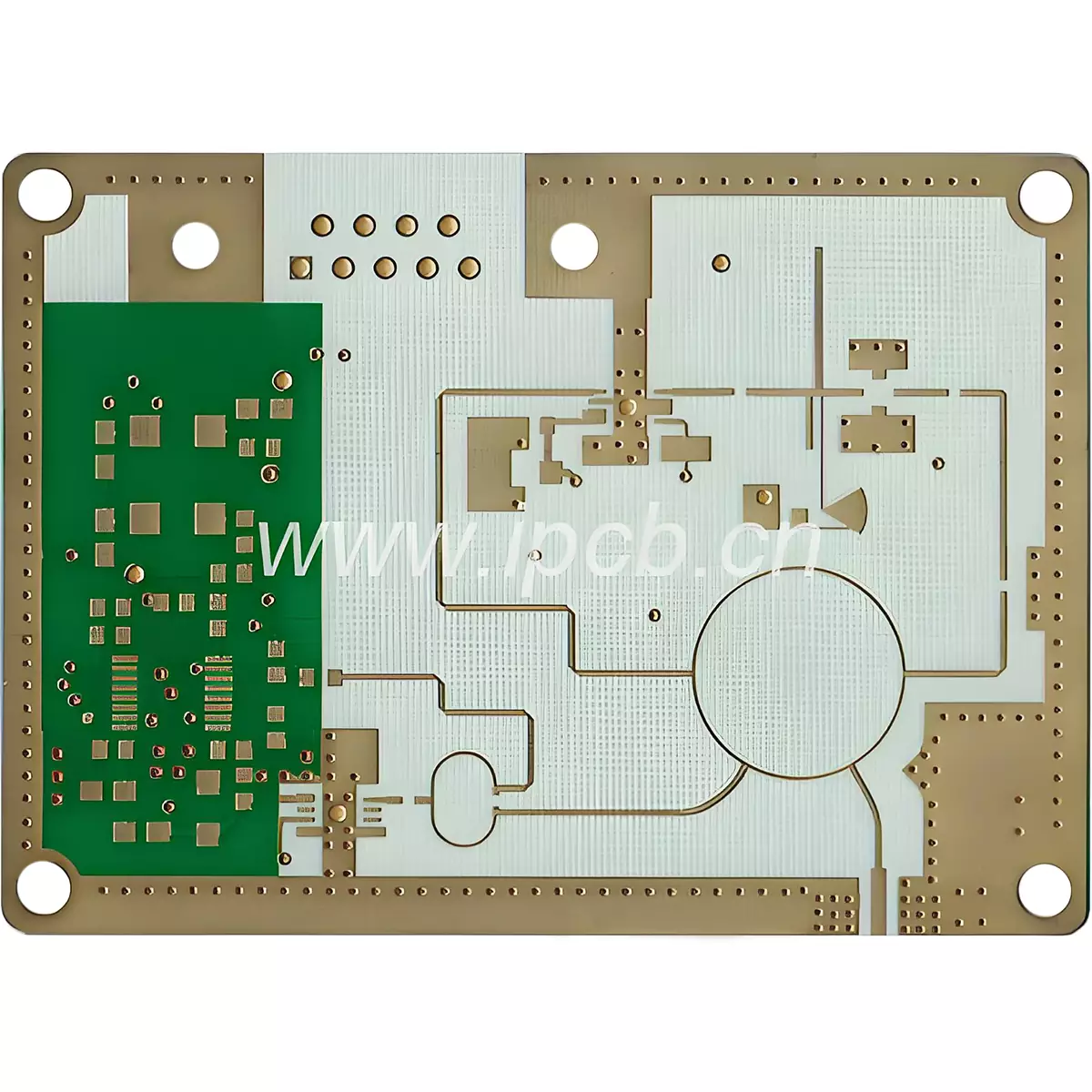

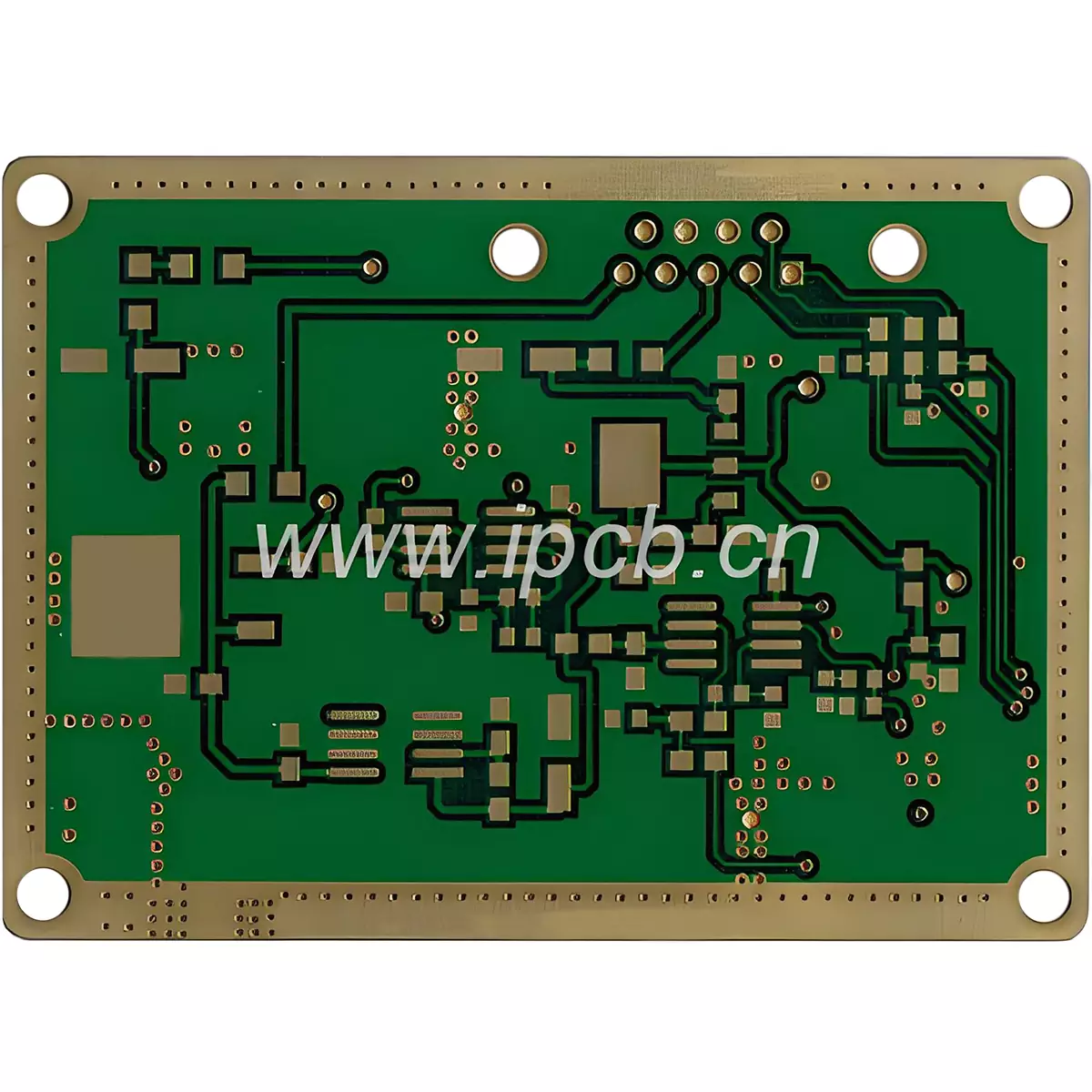

Product Name: RO4350B PCB + FR-4

Material: Rogers RO4350B

FR-4 Material: ITEQ IT180

Quality standard: IPC 6012

Rogers RO4350B Dk: 3.48

Rogers RO4350B Df: 0.0037

Material composition: Ceramics+Hydrocarbons

Layer: 4Layers

Thickness: 1.2mm

Copper thickness: 1oz

Surface technology: ENIG

Application: Communication, Instruments

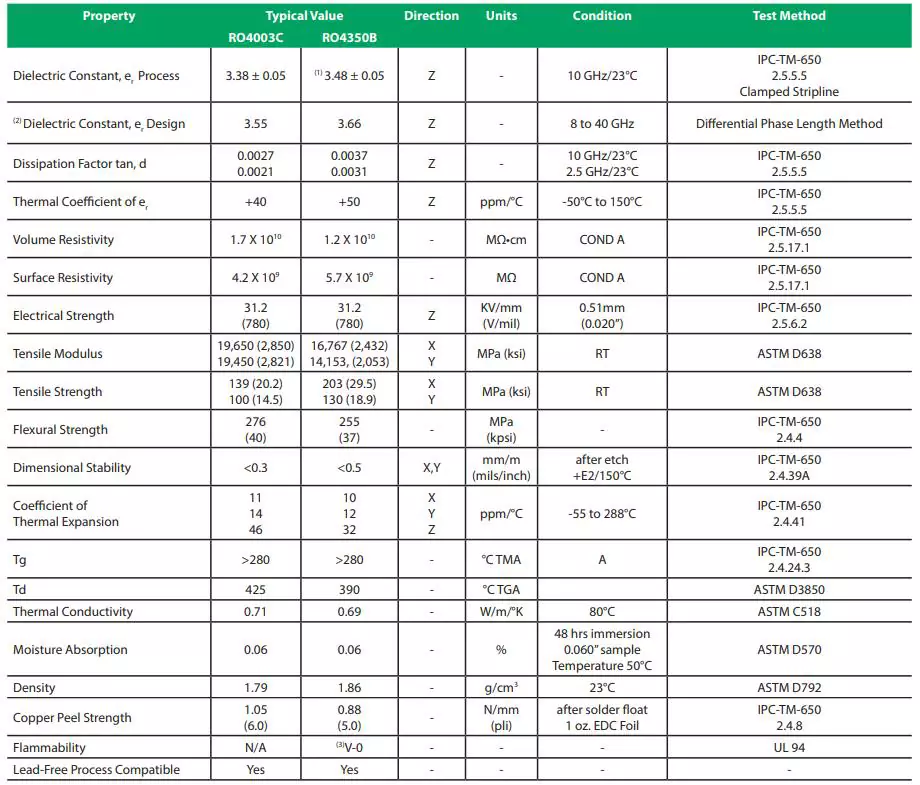

The dielectric constant (Dk) of RO4350B PCB has strict tolerance control and low loss characteristics, and its processing method is the same as standard epoxy resin/glass. The RO4350B PCB circuit board does not require special through-hole processing or operation procedures like PTFE material, and the processing cost is much lower than traditional microwave circuit boards. The material meets UL 94 V-0 flame retardant rating and is suitable for active devices and high-power RF designs.

RO4350B PCB characteristics: Dk 3.48+/-0.05; Df 0.0037@10GHz ; Z-axis thermal expansion coefficient 32 ppm/° C

RO4350B PCB advantages : Similar processing technology to FR-4 PCB, lower cost; High cost-effectiveness; Excellent dimensional stability

RO4350B PCB application: cellular base station antenna and power amplifier; Microwave point-to-point connection (P2P), automotive radar and sensors, radio frequency identification (RFID) tags, high-frequency heads (LNBs) for live broadcasting satellites, circuit board locomotives, circuit board rail transit, circuit board power, circuit board renewable energy, circuit board body and chassis, circuit board lighting, circuit board in car, circuit board in car communication, circuit board in car entertainment, circuit board in car networking, circuit board equipment and inverter power supply, circuit board defense industry equipment, circuit board industrial automation, circuit board industrial servo, circuit board indoor lighting, circuit board smart home, circuit board industrial equipment control, circuit board mobile phone related, circuit board electric vehicle power system, circuit board communication equipment, circuit board safety system, circuit board Internet of Things, circuit board Warehousing, digital applications for circuit boards, such as servers Router and high-speed backplane, circuit board cellular base station antenna and power amplifier, circuit board for lnb of live satellite, circuit board RFID tag.

The RO4350B LoPro PCB circuit board adopts Rogers' proprietary technology, which allows reverse processing of foil materials combined with standard RO4350B dielectrics. This enables the PCB circuit board to have low conductor loss to improve insertion loss and signal integrity, while maintaining all other desirable properties of the standard RO4350B PCB circuit board system.

The RO4350B ceramic PCB circuit board is designed to provide excellent high-frequency performance and low-cost circuit board manufacturing. The result is a low loss material that can be manufactured using standard epoxy resin/glass (FR-4) technology at a competitive price.

Once the operating frequency increases to 500 megahertz or above, the number of laminated materials typically available for designers to choose from will significantly decrease. The RO4350B material has the performance required by designers of RF microwave circuits, matching networks, and controllable impedance transmission lines. The low dielectric loss makes the RO4350B series materials suitable for many applications where high operating frequencies limit the use of traditional circuit boards (PCBs). The temperature coefficient of dielectric constant is the lowest among all circuit board materials, and the dielectric constant remains stable over a wide frequency range.

This makes it an ideal substrate for broadband applications.

The coefficient of thermal expansion (CTE) of RO4350B material provides several key benefits for circuit designers. The expansion coefficient of RO4350B material is similar to that of copper, which gives the material good dimensional stability, which is a characteristic required for mixed medium multilayer board structures.

The low Z-axis CTE of the RO4350B laminate provides reliable electroplated through-hole quality, even in severe thermal shock applications. The Tg of the RO4350B series material is greater than 280 ° C (536 ° F), so its expansion characteristics remain stable throughout the entire circuit processing temperature range.

Using standard FR-4 circuit board processing technology, the RO4350B series PCB circuit board can be easily made into printed circuit boards. Unlike high-performance materials based on polytetrafluoroethylene, the RO4350B series PCB circuit board does not require special preparation processes such as sodium etching. This material is a hard thermosetting PCB circuit board that can be processed through automatic processing systems and scrubbing equipment used for copper surface treatment.

Product Name: RO4350B PCB + FR-4

Material: Rogers RO4350B

FR-4 Material: ITEQ IT180

Quality standard: IPC 6012

Rogers RO4350B Dk: 3.48

Rogers RO4350B Df: 0.0037

Material composition: Ceramics+Hydrocarbons

Layer: 4Layers

Thickness: 1.2mm

Copper thickness: 1oz

Surface technology: ENIG

Application: Communication, Instruments

iPCB Corporation provides support for PCB Prototype and Electronic Manufacturing. You can request consultation or quotation for PCB, PCBA and ODM here, please contact email: sales@ipcb.com

We will respond very quickly.