As the world of electronics continues to evolve, the demand for high-performance printed circuit boards has never been more pressing. In recent years, ceramic PCBs have emerged as a game-changer in the industry, offering unparalleled advantages in terms of stability, thermal conductivity, and reliability. According to IPCB Circuits, a leading manufacturer of high-quality PCBs, ceramic circuit boards have revolutionized the way electronic products are designed and manufactured.

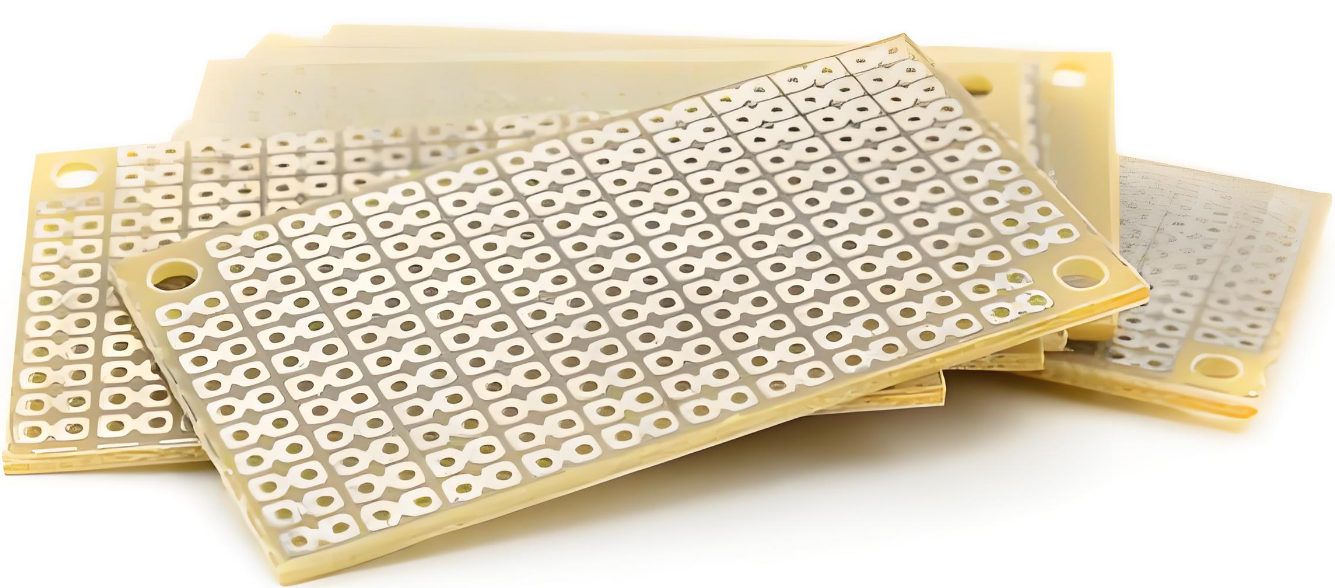

Ceramic PCBs

The Benefits of Ceramic PCBs

Ceramic PCBs boast a multitude of advantages that make them an attractive choice for a wide range of applications. Some of the key benefits include:

High Stability: Ceramic PCBs are manufactured using magnetron or vacuum sputtering technology, which creates a strong bonding force between the copper circuit and the ceramic substrate. This results in a highly stable and reliable PCB that can withstand various environmental stressors.

Higher Current Carrying Capacity: Ceramic PCBs have a significantly higher thermal conductivity than traditional glass epoxy PCBs, allowing them to efficiently remove heat generated by high-current copper tracks. This makes them ideal for PCBs that require high-power electronic modules.

High Thermal Conductivity: Ceramic substrates can achieve thermal conductivity levels of up to 230 W/m.K, depending on their material composition and preparation methods. This is significantly higher than traditional materials like alumina and aluminum nitride.

Low Thermal Resistance: The high thermal conductivity of ceramic substrates translates to low thermal resistance, making them suitable for PCBs that require efficient heat management.

Low Dielectric Loss: Ceramic substrates exhibit low dielectric loss when subjected to electromagnetic fields, making them an excellent choice for applications that require high-frequency switching power supplies.

Low Dielectric Constant: Ceramic PCBs are highly stable in extreme environmental conditions, thanks to their low dielectric constant. This ensures that devices using ceramic PCBs remain reliable and safe even in high-humidity and high-temperature environments.

High Dielectric Strength: Ceramic substrates can withstand high electrical voltages before breaking down, making them superior insulating materials for high-voltage applications.

High Volume Resistivity: Ceramic substrates have a high volume resistivity, even at elevated temperatures, which translates to excellent electrostatic discharge (ESD) safety and protection for sensitive components.

High Cosmic Ray Resistance: Ceramic PCBs are highly resistant to cosmic ray radiation, making them an attractive choice for aerospace and military applications.

Overcoming the Challenges

While ceramic PCBs offer numerous advantages, they also present some challenges. These include:

High Cost: Ceramic PCBs are more expensive than traditional PCBs, although their cost-to-performance ratio is often lower.

Highly Fragile: Ceramic PCBs are brittle and require careful handling to avoid damage.

Low Availability: The limited availability of ceramic PCBs can drive up costs and lead times.

Conclusion

Despite the challenges, the advantages of ceramic PCBs make them an increasingly popular choice for a wide range of applications, including solar panel components, high-power electronic modules, high-frequency switching power supplies, automotive electronics, solid-state relays, high-power LED lighting products, aerospace and military electronics, and communication electronics. IPCB Circuits is a leading manufacturer of high-quality PCBs, including ceramic PCBs. For specific requirements or to learn more about the benefits of ceramic PCBs, please contact IPC Circuits today.

Updated Information

Recent advancements in ceramic PCB technology have led to the development of new materials and manufacturing processes, further enhancing their performance and reliability. Some of the latest trends in ceramic PCBs include:

Advanced ceramic materials: New ceramic materials with improved thermal conductivity, mechanical strength, and electrical properties are being developed, enabling the creation of more efficient and reliable ceramic PCBs.

3D printing: The use of 3D printing technology is becoming increasingly popular in ceramic PCB manufacturing, allowing for the creation of complex geometries and structures that were previously impossible to produce.

Nano-ceramic materials: Researchers are exploring the use of nano-ceramic materials in PCB manufacturing, which promise to offer even higher thermal conductivity, mechanical strength, and electrical properties than traditional ceramic materials.

As the demand for high-performance PCBs continues to grow, ceramic PCBs are poised to play an increasingly important role in the development of innovative electronic products. With their unparalleled advantages and ongoing advancements in technology, ceramic PCBs are an exciting and rapidly evolving field that holds great promise for the future of electronics.