As the name implies, Flexible printed circuit boards are physically flexible. These PCB are widely used in mechanically sensitive devices because the flexibility allows the circuit board to resist vibrations. Flexible PCB are more durable compared to traditional circuit boards, but the flexible PCB manufacturing process is sensitive and complex.

Due to the lightweight design, the circuit board can take the shape according to the housing, can be packed into a small volume, and the overall size of the final product can be reduced. Flex PCB eliminate the excessive use of wire harnesses and connectors in PCB.

Flex PCB Applications

Rigid boards add some restrictions in product design because they cannot be installed in limited spaces. Circuit boards need to be vibration-resistant in products that are often subjected to mechanical shock.

Flex PCB are more suitable for this situation because they can be bent and wrapped if needed. They can survive harsh temperatures ranging from -200 to 400 degrees Celsius. These features make flexible circuit boards more reliable and durable compared to traditional circuit boards.

Computers and Accessories

Flexible PCB are very robust in terms of signals and atmospheric conditions. Hard drives in computers contain Flex PCB. Since these PCB provide high data transfer rates on physically small circuit boards. Other electronic devices such as printers, calculators, and laptop LCDs are often designed with flexible PCB for similar reasons.

Aircraft

Aircraft electronic systems are often crammed with cables and they need to be lightweight. A typical Airbus contains nearly 100 kilometers of cables, while a helicopter contains about 12 kilometers of cables. When it comes to the reliability and performance of aircraft systems, there can be no compromise. Flexible PCB reduce weight and significantly improve even when subjected to mechanical shocks, making them ideal for aircraft.

Automobile

Automotive products are becoming more and more compact as time goes by. Flexible PCB add compactness to their designs because, regardless of the shape, these PCB can be placed in limited spaces and still work efficiently. Flex PCB enable designers to produce lightweight products while maintaining product performance.

Flexible PCB are often used in engine management computers, airbag controllers, and other electronic components of automotive products. Since cars are often exposed to high temperatures, which is tolerable for flexible PCB, these boards feature in modern automotive products.

Mobile phones

Mobile phones are small in size, but they have a lot of features. Ever wondered how to design dense circuits in such a compact housing? Flexible PCB enable the synchronization of multiple components while requiring minimal space.

Connecting wire harnesses or rigid boards for synchronizing components is disadvantageous because of the limited size and shape of mobile phones. In addition, mobile phones heat up, and traditional circuit boards cannot withstand high temperatures. In addition, Flex PCB also add waterproofing to the design.

Nowadays, mobile phones, digital books are developing flexible PCB, which is a major technological breakthrough. Imagine wrapping a mobile phone or bending the pages of a digital book? It is impossible using rigid PCB, with the advancement of technology, Flexible PCB are also developing and hopefully in the near future, we will be able to bend mobile phones like pages.

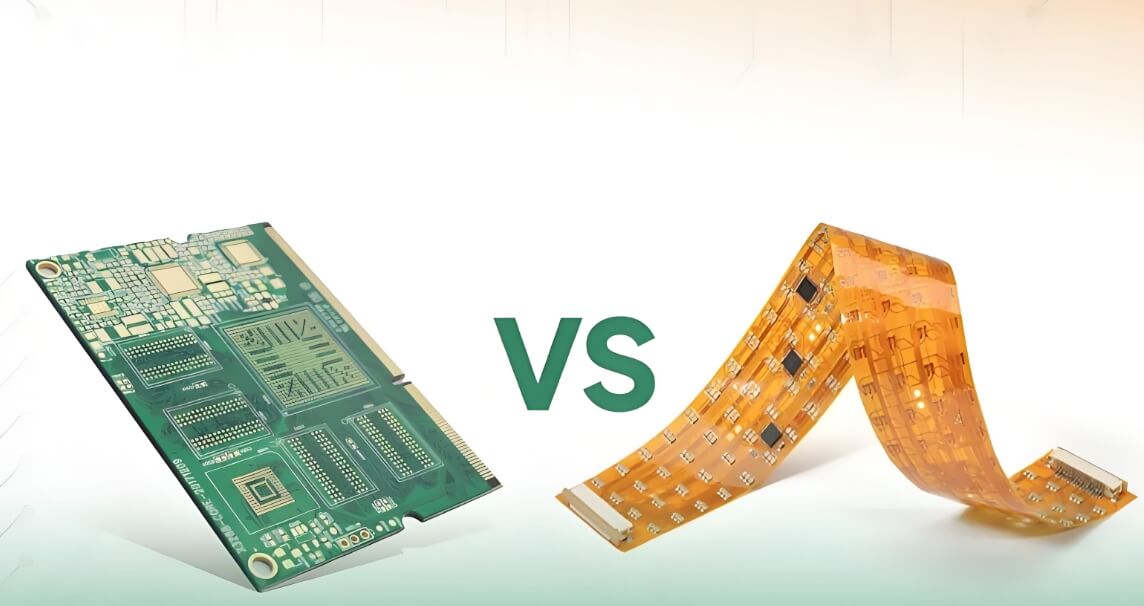

Flexible PCB vs Traditional PCB

Medical Electronics

Medical electronics need to be highly precise and durable. Wearable devices currently being developed are often developed using Flexible PCB, and their flexibility makes them suitable for host use.

Today, wearable devices are used to track physical health, and these gadgets are very compact and delicate. Flex PCB can implant sensors on the patient's skin and the results can be monitored on a smart watch or mobile phone. This revolution in wearable medical devices is brought about by flexible PCB.

Medical devices often need to be placed inside the human body, such as pacemakers or pill cameras are often exposed to extreme atmospheric conditions and flexible PCB are best suited for this situation.

Rigid PCB are bulky, cannot adopt shape changes and have low performance when high signal transmission, which makes them unfavorable for medical electronics.

Recent research on Flexible PCB has enabled scientists to develop Flex PCB that are more suitable for medical devices. Developed using organic materials, these PCB provide a more suitable quality for prosthetic parts. These boards are more flexible compared to flexible conventional PCB, which is exciting for the development of high-performance prosthetics.

Industrial Applications of Flex-Rigid PCB

Flexible PCB can withstand extreme weather conditions and perform well even in harsh environments. RF devices are often designed using Flex PCB as the robust nature of these PCB keeps the signal strength unaffected.

Also, industrial machines and power distribution control systems have adopted Flex PCB.

Sensors

Flex PCB have revolutionized sensors, and modern sensors are manufactured on flexible PCB, which reduces their size. These sensors can be placed in limited and irregular spaces, suitable for designing or more compact products.

Military Equipment

Most modern military equipment uses Flex PCB such as radar systems in military vehicles. Control systems in military-grade equipment require high signals and robustness of conductive paths. Since the equipment has to be used in extreme temperatures, the weather conditions are usually difficult to withstand for rigid PCB. Also, military equipment is often subject to vibrations and mechanical stress, which are easily tolerated by flexible PCB. For these reasons, Flex PCB are best suited for military equipment.

Flexible PCB offer greater flexibility, lightweight design, and durability compared to traditional PCB, making them ideal for applications in industries like automotive, medical, and consumer electronics. Their growing demand highlights their advantages in modern technology where traditional PCB may fall short.