With the continuous increase in power density of electronic circuit design, the trend towards miniaturization of product size, and the continuous improvement of product reliability requirements, PCB designers tend to choose heat-resistant and high reliability copper-clad board materials when selecting circuit board materials. So how to deal with several common parameters of copper-clad laminates: Tg, Td, T300?

The resin of PCB has three mechanical states, namely glassy state, highly elastic state, and viscous state.

Glass state: At low temperatures, the material is in a solid state, similar to glass, and only undergoes very small deformation under external forces. This state is called the glass state.

High elastic state: When the temperature rises to a certain range, the deformation of the material increases significantly and becomes relatively stable within a certain temperature range thereafter, which is called high elastic state.

Viscous flow state: As the temperature continues to rise, the deformation of the material gradually increases, and the material gradually becomes a viscous fluid. At this point, the deformation cannot be restored, and this state is called viscous flow state.

We call the transition between the glassy state and the highly elastic state the glass transition, and the temperature corresponding to it is the glass transition temperature.

At present, the methods used for determining the glass transition temperature include differential thermal analysis (DSC), dynamic mechanical property analysis (DMA), thermo mechanical analysis (TMA), nuclear magnetic resonance (NMR), and dynamic dielectric analysis (DETA). Currently, the main method used is differential thermal analysis (DSC).

Glass Transition Temperature (Tg): The temperature at which a polymer transitions from a glassy state to a highly elastic state. The glass transition temperature is an important parameter for physical changes in polymers, mainly related to the structure, aggregation state, crosslinking density, and other factors of the polymer. For designers, Tg is an important item for measuring and characterizing the heat resistance of some fiberglass cloth based copper-clad laminates (such as FR-4). In the IPC-4101 standard, the minimum Tg index value or Tg index range is specified for various types of copper-clad laminates based on fiberglass cloth, which is actually used to divide the heat resistance level of each type of board based on Tg. For example: Tg140 ℃, Tg160 ℃, Tg180 ℃, and so on. So, for high reliability designs, designers tend to choose high Tg boards. Tg, as a symbol for the heat resistance of sheet metal in lead welding, is indeed representative.

However, since the implementation of WEEE and RoHS by the European Union, it marks the global electronics industry entering the era of lead-free soldering. ROHS will directly affect the reflow soldering and wave soldering conditions during the installation process of electronic products, including repair soldering temperature: typical lead-free reflow soldering condition temperature: 245-265 ℃, maintained for 1 minute; The repair welding temperature peak will reach 300 ℃ and maintain for a few seconds. After the emergence of lead-free soldering, based on mass production experience, the author found that the high or low Tg can no longer express whether the board can withstand higher temperatures and greater heat. Some FR-4 products have a Tg of 180 ℃, but a Td lower than 330 ℃, making them unsuitable for lead-free processes. So IPC has a further demand for more precise indicators - the requirement for lead-free compatibility with FR-4: Td ≥ 340 ℃; T300 ≥ 2min, Z-CTE ≤ 3.5% (50-260 ℃).

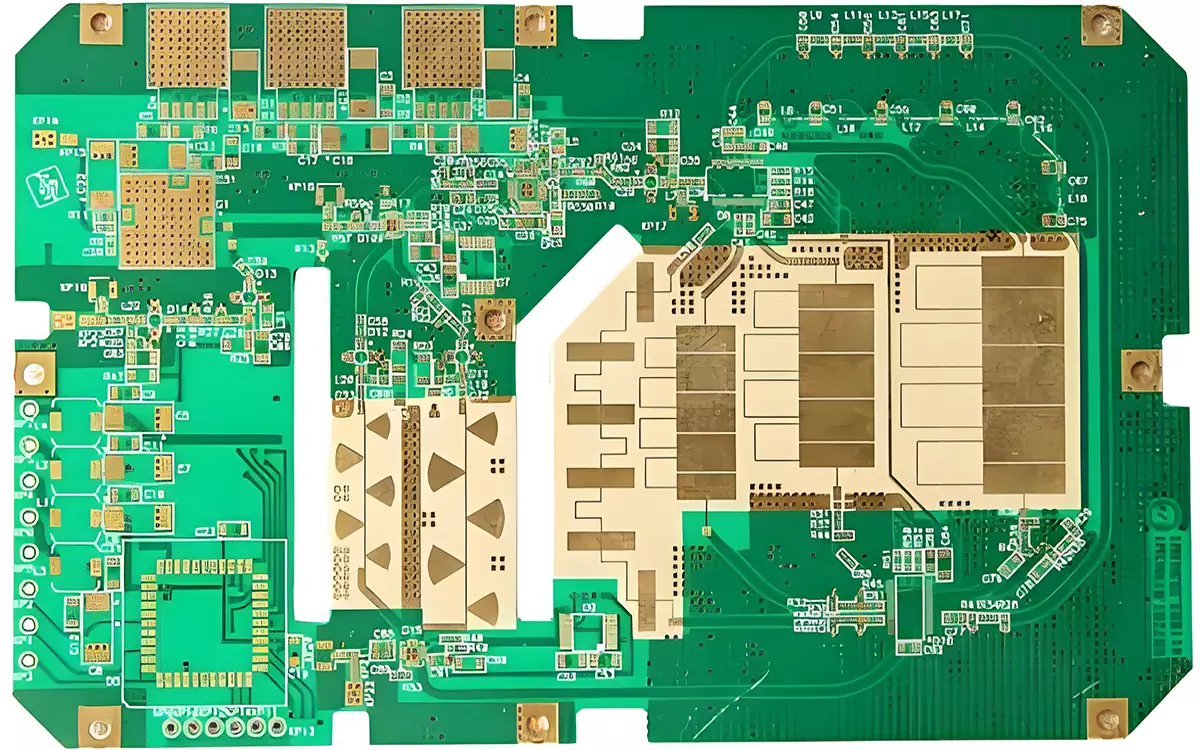

PCB

Td (Thermal decomposition temperature): The temperature at which a polymer begins to decompose. For copper-clad laminates, it refers to the temperature at which the sheet decomposes upon heating and the heat loss reaches 5%.

T300 thermal delamination time refers to the time it takes for a copper-clad laminate to be placed at a certain temperature, heated at a constant rate to a set temperature of 300 ℃, and kept at that temperature until irreversible thickness changes occur in the specimen - i.e. delamination.

The higher the TD value, the higher the T300, and the better the reliability of the PCB, which can better meet the requirements of lead-free processes. Especially when the design requires multiple pressing and lead-free soldering requirements.

The higher the Tg value of the PCB board, the better its high temperature resistance and deformation resistance. The advantages in application are reflected in the following aspects.

In the PCB production process, the higher the Tg, the smaller the deformation and the better the dimensional stability, which is very important for PCBs with high multi-layer, high-precision, and high-density circuits.

Dimensional stability means that the graphic deformation of each layer of the circuit is smaller, the reserved position accuracy redundancy in the design is smaller, and the wiring density can be higher, thus achieving a more compact and lightweight PCB; At the same time, the positional accuracy of solder pads and holes is also higher, which is beneficial for welding production.

During welding, the higher the Tg, the better the heat resistance performance during high-temperature welding, ensuring that high-performance boards have minimal deformation during welding, resulting in smaller shear and tensile stresses between SMD pins and board surface pads, improving the quality (or uniformity) of solder joints, and enhancing assembly reliability.

For example, Rogers PCB 92ML is a copper-clad laminate product that incorporates high thermal conductivity ceramic fillers into a flame-retardant epoxy resin system and is supported by electronic grade fiberglass cloth. 92ML TC=2W/MK, although Tg is only 160 ℃, TD reaches 400 ℃, T300>5min, easily meeting the requirements of lead-free processes. Moreover, 92MLHF is an environmentally friendly material that meets halogen free requirements. For designs with demanding work environments and high heat dissipation requirements, 92MLHF is an ideal board choice.