In the realm of printed circuit board design, the intricacies of via types can significantly influence both performance and manufacturability. Among these, blind vias and buried vias play crucial roles in optimizing space and enhancing circuit functionality, particularly in advanced applications where size constraints and performance standards are paramount. This article delves into the nuances of these via types, elucidating their construction, advantages, and applications in modern electronics.

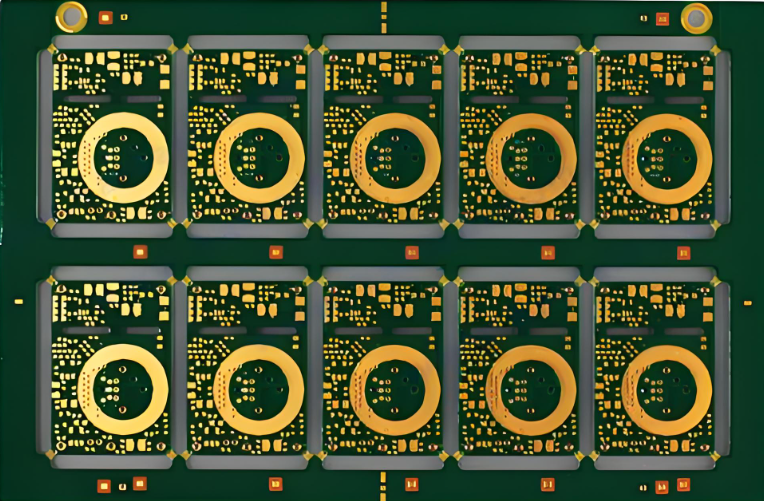

Blind and Buried PCBs

Defining PCB Vias:

A PCB via, commonly referred to as a through hole, is a plated hole that connects various layers of a PCB. For instance, in a four-layer PCB, the via extends through all four layers, facilitating electrical connection throughout the board.

Types of PCB Vias:

Plating Through Hole (PTH): This type of via is characterized by copper plating on its walls and is typically used for current-carrying pathways and component connections. PTHs can serve as both VIA pads for components and connection points between layers.

Non-Plating Through Hole (NPTH): In contrast, NPTHs lack copper plating on their walls. They are primarily utilized for positioning components and creating holes for screws, thus not contributing to the electrical pathways.

Blind Vias

Blind vias are drilled from the outer layers of a PCB but do not extend through the entire thickness of the board. They connect the outer layer to one or more inner layers, allowing for efficient routing without disturbing the inner traces. Typically employed in PCBs with four or more layers, blind vias are advantageous in maintaining signal integrity since they isolate circuit paths.

However, the fabrication of blind vias requires specialized equipment, such as laser drilling machines, which can increase production costs. Nevertheless, their use can significantly optimize layout by saving space, minimizing layer count, and improving overall electrical performance.

Buried Vias

Buried vias, on the other hand, are entirely enclosed within the layers of the PCB and are not visible from either side of the board. These vias interconnect the inner layers, effectively "burrowing" through the PCB without occupying surface space. As a result, buried vias enhance the routing density, enabling more complex circuit designs.

Typically found in PCBs with six or more layers, buried vias are advantageous when creating high-density interconnections within compact spaces. However, their complexity and the cost of manufacturing make them more suited for high-end applications rather than standard electronic products.

The Impact of Via Type on PCB Design

The integration of blind and buried vias offers substantial benefits for HDI PCBs. By minimizing the number of traditional through holes, manufacturers can reduce overall board size, enhance electromagnetic compatibility (EMC), and improve thermal performance. Additionally, the reduction of through holes helps in maintaining integrity within power and ground planes, ensuring better overall performance.

With advancements in laser drilling and plasma etching technologies, the ability to fabricate smaller non-through vias has become increasingly feasible. For instance, vias drilled with diameters as small as 0.3 mm can lead to significantly reduced parasitic parameters, enhancing PCB reliability.

Moreover, adopting these via technologies allows designers to use remaining space more effectively. It enables shielding large planes or critical signal traces, optimizing electromagnetic interference (EMI) performance, and enhancing circuit efficiency.

Challenges of Blind and Buried Vias:

Despite their advantages, blind and buried vias do present certain challenges. The increased cost of HDI boards and the complexities associated with their processing can pose significant hurdles. Testing and troubleshooting become more intricate due to their concealed nature; therefore, careful consideration is necessary when designing PCBs with these via types.

Furthermore, the constraints on board size and layer count can limit the application of blind and buried vias, making them suitable primarily for high-performance devices in such industries as telecommunications, aerospace, and medical technology where reliability and miniaturization are critical.

Conclusion

Blind and buried vias represent a significant evolution in PCB design, offering solutions that cater to the demands of modern electronics, including size reduction and enhanced performance. As technologies continue to evolve, the role of these via types will likely expand, providing engineers and designers with ever-more sophisticated tools to push the boundaries of what's possible in PCB development.