What is a PCB Circuit Board?

A PCB, or PCB Circuit Board, is a fundamental electronic component that serves as a physical base for mounting electronic components and establishing electrical connections between them. The term "printed" refers to the process through which these boards are manufactured, utilizing advanced electronics printing techniques.

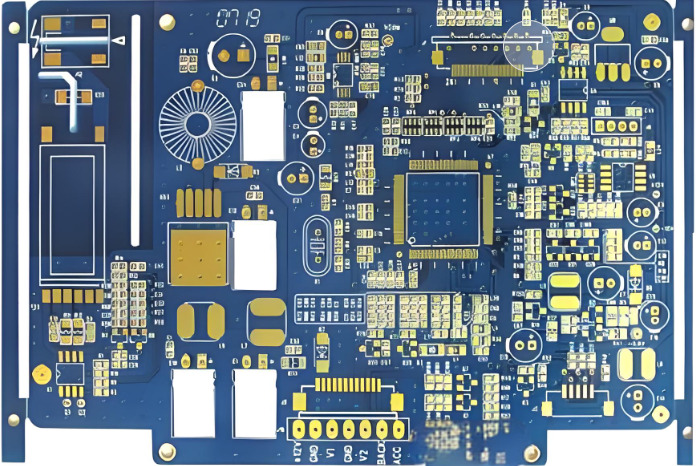

PCB Circuit Board

What Do You Know About Circuit Boards?

Printed Circuit Boards are ubiquitous in modern electronics, supporting a wide array of devices from simple gadgets to complex systems. Their design and construction are pivotal in ensuring the functionality and reliability of electronic products.

Advantages of PCB Circuit Boards

The adoption of PCBs in electronic equipment offers numerous benefits:

Consistency and Precision: The uniformity of PCBs minimizes manual wiring errors that can occur during traditional assembly methods.

Automation: PCBs facilitate the automatic insertion and installation of components, along with automated soldering and inspection processes. This automation enhances product quality and efficiency.

Cost Reduction: By streamlining the manufacturing process, PCBs help lower production costs while improving labor productivity.

Ease of Maintenance: The structured layout of PCBs simplifies troubleshooting and repairs, making maintenance more straightforward.

Classification of PCB Circuit Boards

PCBs can be classified based on their number of circuit layers:

Single-Sided PCBs: Contains one layer of conductive material.

Double-Sided PCBs: Features conductive layers on both sides of the board.

Multi-Layer PCBs: Consists of multiple layers typically four to six layers in common applications but can have numerous layers for more complex designs.

Unique Attributes of PCB Circuit Boards

The widespread use of PCBs is attributed to their distinctive advantages, which include:

Enhanced reliability

High manufacturability

Testability and assemblability

Ease of maintenance

PCB Circuit Board Production Process

The production of PCBs involves several critical steps:

Cutting: Initial sizing of the board.

Inner Layer Formation: Creating the internal circuitry.

Lamination: Bonding layers together.

Drilling: Creating holes for component leads and vias.

Copper Deposition: Applying copper to the board.

Circuit Drawing and Etching: Defining the circuit paths.

Solder Mask Application: Protecting the conductive paths.

Printing Identification: Adding labels and markings.

Finishing: Applying a surface finish, such as tin or gold.

Edge Profiling: Trimming and shaping the board.

Flying Probe Testing: Conducting electrical tests.

Vacuum Packaging: Ensuring protection during transport.

Soldering Process Standards

When soldering PCB components, it is essential to adhere to rigorous standards for quality and safety:

Static Electricity Protection: Implement measures for grounding and preventing static discharge.

Soldering Steps:

Remove any components carefully by cleaning the targeted solder joints.

Heat the soldering points with an electric soldering iron.

Use a solder sucker to eliminate old solder.

Insert new components accurately.

Reheat the solder joints and apply fresh solder.

Joint Inspection: Finally, verify that the solder joints are smooth, shiny, robust, and securely connected with the surrounding components.

By understanding the fundamentals of PCB circuit boards, their advantages, classifications, production processes, and soldering standards, you can appreciate their essential role in modern electronics.