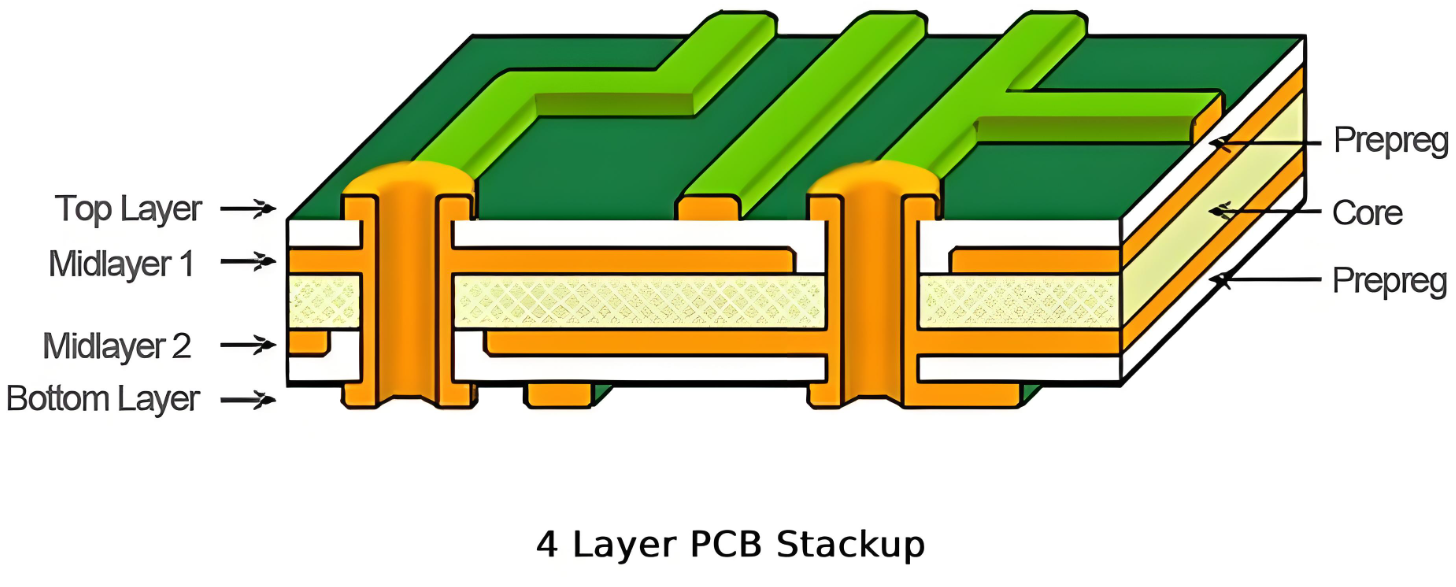

In the design and manufacturing of multilayer printed circuit boards, prepreg and core materials are fundamental to the mechanical strength, electrical performance, and thermal stability of the final product. While they serve different roles in the PCB stack-up, both materials are essential, and understanding their distinctions and interplay is critical for successful board fabrication especially in high-speed and high-frequency designs.

What Is a Core laminate in PCB?

A PCB core is a fully cured, rigid sheet of dielectric material—typically made from FR-4 that is clad with copper foil on both sides. Essentially, it's a double-sided PCB in itself and forms the building block of multilayer boards.

The core is fabricated under high temperature and pressure, which hardens the epoxy resin and creates a strong, dimensionally stable layer. Because it is already cured, the core contributes to the structural rigidity of the final PCB and provides a reliable base for circuit etching, plating, and lamination.

Key Characteristics of PCB Cores:

Made from cured FR-4 or other laminate materials

Copper foil laminated on both sides

Offers defined mechanical and dielectric properties

Commonly used as the central layer in multilayer PCBs

What Is Prepreg laminate in PCB?

Prepreg, short for“pre-impregnated,”refers to a dielectric material made of woven fiberglass cloth that is partially impregnated with a resin system. Unlike the core, prepreg is not fully cured. It remains tacky or semi-cured, which allows it to act as an adhesive and insulating layer during the lamination process.

When fabricators stack multiple layers of PCB cores or copper foils, prepreg is placed between them. During the lamination process, heat and pressure cause the resin in the prepreg to melt, flow, and bond to the adjacent copper or core layers. As the resin cures fully, it solidifies the entire multilayer stack into a monolithic structure.

Functions of Prepreg:

Acts as a bonding agent between cores or copper layers

Provides electrical insulation between signal layers

Contributes to the final board thickness and dielectric spacing

Enables mechanical integrity across the board stack-up

Prepreg vs. Core: Key Differences

Although prepreg and core materials are derived from similar base materials typically fiberglass cloth and epoxy resin they differ significantly in structure, curing state, and application.

Feature | Core | Prepreg |

Curing State | Fully cured and hardened | Semi-cured or B-stage resin |

Copper Cladding | Copper on both sides | No copper (usually) |

Primary Function | Structural base layer | Adhesive and dielectric layer |

Role in Lamination | Inner layer with etched circuitry | Bonds layers during lamination |

Contribution | Provides mechanical stability | Controls dielectric spacing |

Variations in Prepreg and Core Materials

Different grades and types of prepreg and core materials are available to suit varying performance requirements, including:

Glass weave types: For example, 7628 (loose weave) and 1080 (tight weave), which impact dielectric consistency and signal integrity.

Resin systems: Traditional DICY-cured epoxy systems are giving way to non-DICY and phenolic-based resins, which offer:

Higher glass transition temperatures (Tg)

Improved thermal stability

Enhanced electrical insulation

Reduced conductive anodic filament (CAF) growth

Prepreg and Core in High-Speed, High-Frequency, and Complex PCBs

In modern high-speed and RF/microwave applications, dielectric constant (Dk) and loss tangent (Df) play a critical role. Variability in Dk between the prepreg and core layers can introduce impedance mismatches, signal dispersion, and timing skew—especially in differential pairs or transmission lines.

For designs requiring controlled impedance, fabricators must carefully select compatible materials with matched electrical properties. Tools such as field solvers and stack-up modeling software are often used to simulate the effective dielectric constant and optimize layer placement.

In complex PCBs, such as HDI or boards with blind/buried vias, multiple prepreg types may be combined in a single stack-up to achieve the desired mechanical and electrical characteristics.

Fabrication Considerations for Multilayer Boards

During lamination, the quality of the bonding between prepreg and core layers determines the reliability of the entire board. Key factors include:

Cleanliness of bonding surfaces

Proper storage and shelf life of prepreg (to prevent premature curing or moisture absorption)

Controlled lamination temperature and pressure profiles

Use of press plates and release films to prevent surface defects

Fabricators also adjust the number of prepreg plies and resin content to meet the target board thickness and dielectric spacing. Consistent resin flow is crucial for avoiding voids, delamination, or warping during manufacturing.

Conclusion

According to IPCB, for multilayer PCB fabrication, prepreg is not just optional,it’s essential. Without prepreg, there would be no structural or electrical bonding between the inner layers of the PCB stack. Together, prepreg and core materials form the physical and electrical backbone of a reliable, high-performance printed circuit board.

Whether you’re developing advanced communication systems, automotive electronics, or industrial control devices, a deep understanding of the relationship between prepreg and core will ensure superior PCB performance and long-term product reliability.