What is PCB conformal glue?

PCB conformal adhesive , also known as circuit board conformal adhesive or coating adhesive, is a specially formulated coating adhesive used to protect printed circuit boards (PCBs) and related equipment from environmental factors. It can form a protective film on the surface of the PCB, which has multiple protective functions, thereby improving the reliability and service life of the PCB. The main components of PCB conformal adhesive may include acrylates, silicones, polyurethanes, nanomaterials, etc., which have different properties and application scenarios.

The role of PCB three-proof adhesive

The role of PCB three-proof glue is mainly reflected in the following aspects:

Waterproof and Moisture Resistant:

PCB triple-proof glue can effectively prevent moisture from penetrating into the circuit board and avoid moisture damage to electronic components.

It can provide good waterproof performance in humid environments and protect circuit boards from electrical performance degradation and material expansion caused by moisture.

Dust and dirt resistant:

PCB triple-proof glue can prevent dust, fine particles and other impurities from entering the circuit board and keep the circuit clean.

This helps reduce the risk of short circuits between electronic components and improves the stability and reliability of the circuit board.

Shock Protection:

PCB triple-proof adhesive has certain elasticity and shock absorption properties, which can reduce the impact of external shock and vibration on the circuit board and the components therein.

This helps prevent board failure due to physical damage and improves the overall performance of the device.

Anti-corrosion and mildew-proof:

PCB triple-proof glue can prevent circuit boards from being affected by chemical corrosion and mold growth, and protect circuits from erosion by harsh environments.

This helps extend the life of the circuit board and improves the reliability and safety of the equipment.

Insulation protection:

PCB three-proof adhesive has good insulation properties and can protect circuit boards from static electricity and other external electrical influences.

This helps prevent equipment damage or safety incidents caused by electrical faults.

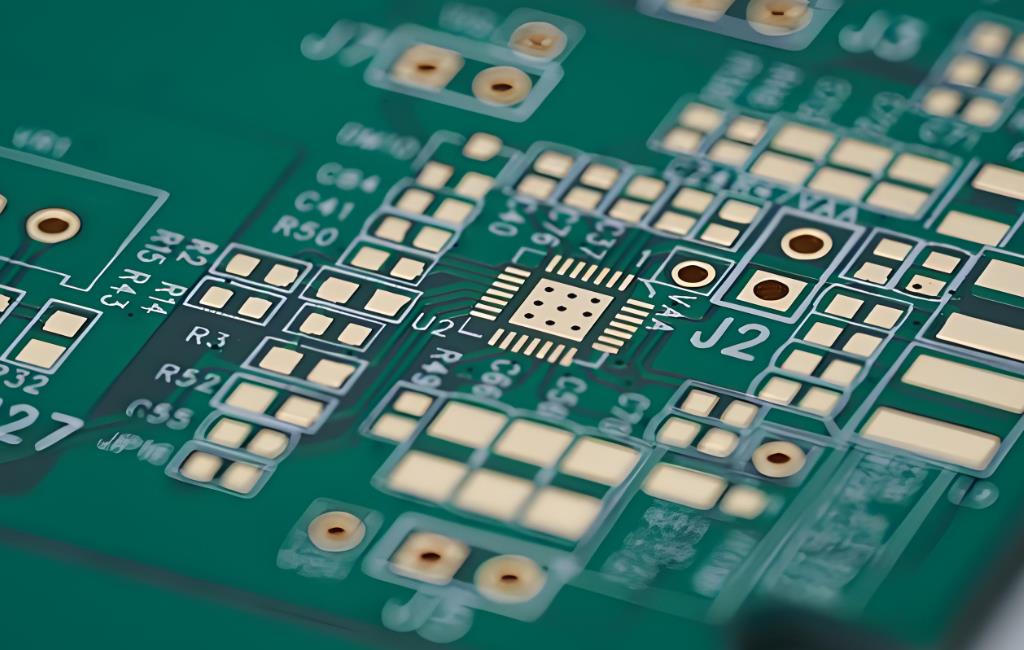

PCB Circuit Board

Improve aesthetics:

After PCB three-proof glue is applied, the surface of the circuit board can be made smooth and the appearance quality of the equipment can be improved.

Application

PCB conformal adhesive has a wide range of applications, especially for electronic devices that need to work in harsh environments or are exposed to water, dust, vibration, etc. These devices include but are not limited to automotive electronics, outdoor equipment,industrial control systems, aerospace equipment, marine equipment, and medical equipment. In these fields, PCB conformal adhesive plays a vital role in protecting circuit boards from environmental factors and ensuring the normal operation and long-term stability of the equipment.

In summary, PCB conformal adhesive is an important protective agent for electronic materials. It protects Printed Circuit Boards and related equipment from environmental factors by forming a protective film with multiple protective functions. With the continuous development of electronic technology and the continuous expansion of application fields, the demand for PCB conformal adhesive will continue to grow.