In the complex world of printed circuit boards (PCBs), one of the potential challenges facing engineers and manufacturers is the presence of harmful ionic contamination. This invisible adversary can wreak havoc on the performance and reliability of electronic devices, so anyone involved in PCB design and production must understand its nuances and, more importantly, how to prevent it.

Let’s dive into the details of PCB ionic contamination, its limitations, the culprits, and how to prevent it according to IPC standards.

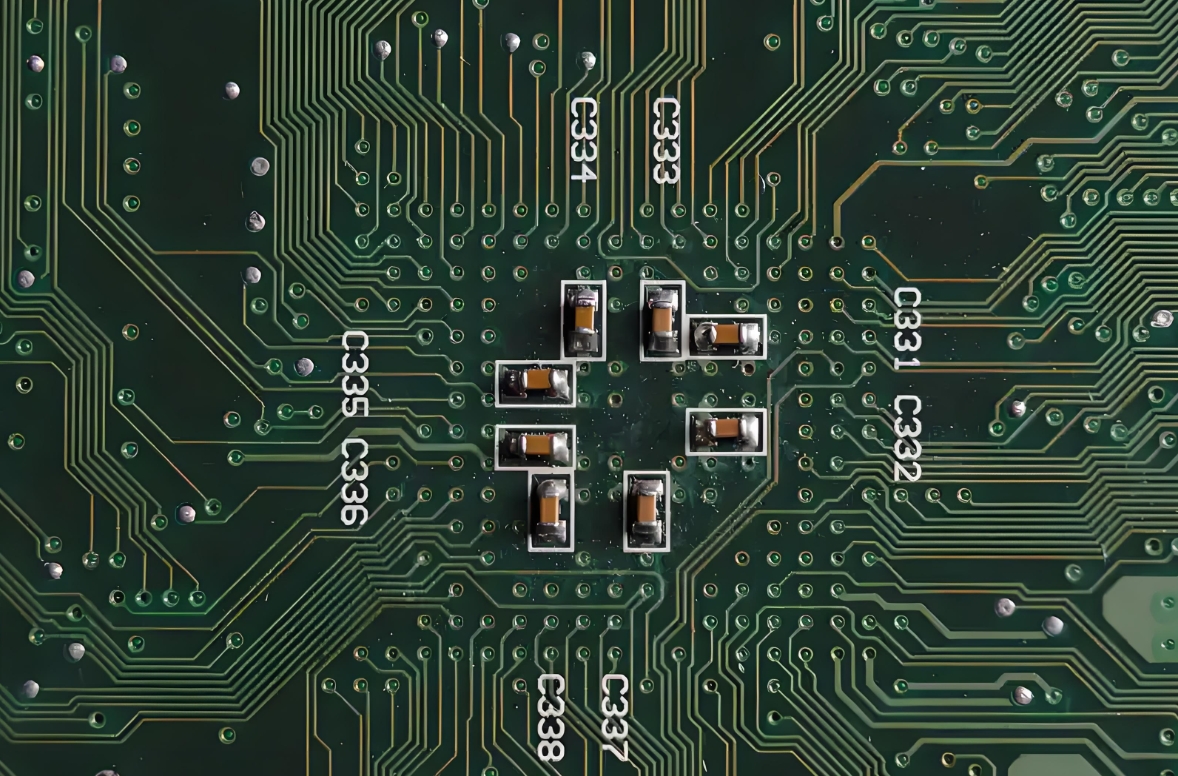

Understanding Ionic Contamination in PCBs

Ionic contamination in PCBs refers to the presence of unwanted charged particles. These particles can come from a variety of sources, such as the environment, the manufacturing process, or the materials used in the PCB itself. They may look insignificant, but don’t be fooled. These small particles can have a big impact, causing corrosion, dendrite growth, and reduced insulation resistance. In short, it’s bad news for PCBs.

Limits of PCB Ionic Contamination

Like an uninvited guest at a party, there is a limit to the amount of ionic contaminationa PCB can tolerate before it gets out of control. The general consensus is that PCB ionic contamination should not exceed 1.56 µg/cm2 (10.06 µg/in2) sodium chloride equivalent for uncoated PCBs. If you exceed this limit, you are in the danger zone.

Understanding Ionic Contaminants

Ionic contaminants are nasty invaders that cause ionic contamination. They can come from flux waste, manual handling, or even the air in the production environment. They are typically composed of anions (such as chloride, bromide, nitrate, and sulfate) or cations (such as sodium, ammonium, potassium, and magnesium). These uninvited guests don’t respond; they just show up and cause problems.

Ionic Contamination

Tips for Preventing Ionic Contamination

Preventing ionic contamination requires a combination of effective tools, specialized materials, and a controlled environment. Here are key strategies:

Cleaning Agents: Isopropyl Alcohol (IPA) and deionized water help remove residues without leaving harmful traces.

Cleaning Wipes & Tools: Anti-static wipes and lint-free swabs prevent static buildup and residue during cleaning.

Ultrasonic Cleaning Systems: High-frequency sound waves remove contaminants by creating bubbles that dislodge particles.

Ionic Contamination Testing: Ion chromatography and conductivity meters help identify and monitor contamination levels.

Environmental Control: Cleanrooms and humidity control systems maintain low contaminant levels in production areas.

Solder Paste & Flux: Low-residue flux reduces the risk of ionic contamination during soldering.

Conformal Coatings: Protective coatings guard against ionic contamination and environmental damage.

Packaging Solutions: Anti-static packaging prevents static buildup and contamination during storage and transport.

Employee Training: Proper training ensures employees follow best practices to prevent contamination.

The Institute for Interconnecting and Packaging Electronic Circuits (IPC) has set standards for maintaining PCB cleanliness and preventing ionic contamination. According to IPC-CH-65B, an effective cleaning process must remove all debris and contaminants from the PCB surface.

IPC also recommends routine testing for ionic contamination to ensure it remains within acceptable levels. This can be done using methods such as ion chromatography (IC) or resistivity solvent extraction (ROSE) testing.

Conclusion

In the world of PCBs, prevention is better than cure. Implementing a robust cleaning process, following IPC guidelines, and regularly testing for ionic contamination can help keep your PCBs in tip-top shape.

Remember, PCBs are like a high-stakes game of Jenga. One wrong move (or in this case, ionic contaminants) can cause the whole thing to fall apart. So stay vigilant, stay clean, and stay away from those ionic contaminants.

Now you’ve got a comprehensive introduction to PCB ionic contamination and how to prevent it. Now you’re fully prepared to tackle this invisible threat head-on and ensure your PCBs are operating as efficiently and effectively as possible.