With the continuous development of Automotive Electronic Technology, Automotive PCB boards, as very important electronic components, are becoming more and more important. The difference between automotive PCB boards and ordinary PCB boards is that they must meet strict safety, reliability and stability standards. This article will discuss the difference between Automotive PCB boards and Ordinary PCB boards, the application of automotive PCB boards, and the future development trend of automotive PCB boards.

1. Differences between automotive PCB and ordinary PCB

In terms of design and manufacturing, automotive PCB and ordinary PCB have the following differences:

PCB material

Automobile PCB uses composite materials, which are prefabricated materials, roughly a combination of two or more materials. This material can not only meet the use requirements of automotive PCB in high temperature and high humidity working environment, but also effectively reduce noise and interference in vehicle circuits.

PCB thickness

The requirements for automotive PCB are more stringent. Ordinary PCB is usually between 0.2 and 3.0 mm, while automotive PCB is usually between 0.6 and 3.2 mm. This is because the working environment of automotive electronic components is relatively harsh, so automotive PCB needs to be more durable and stable in terms of PCB thickness.

PCB circuit design

Automobile PCB not only requires the safety and reliability of the circuit, but also needs to consider the durability and stability of the automotive circuit. Therefore, in the circuit design of automotive PCB, more working environment factors such as temperature, humidity, dust, etc. should be considered.

2. Application of automotive PCB boards

Automobile PCB boards are widely used in automotive electronics, car audio, car multimedia, car navigation and other fields. Automotive PCB boards can not only improve the safety and reliability of automotive circuits, but also improve the working efficiency and performance of automotive circuits. The application of automotive PCB boards includes but is not limited to:

In-vehicle electronics

There are many electronic devices in the car, such as car computers, car audio, car multimedia, etc. These devices require efficient and reliable automotive PCB boards to support them to perform at their best.

In-vehicle navigation

Car navigation is a representative of the new generation of intelligent transportation. It can help car drivers plan the best route and avoid traffic jams and other traffic conditions. As an important part of vehicle navigation, automotive PCB boards can improve the performance and accuracy of vehicle navigation.

Vehicle safety

The automotive safety system includes various sensors, controllers and transmission devices. The safety system must achieve a high degree of reliability and safety to ensure the safety of passengers. This requires automotive printed circuit boards to withstand extreme working environments, such as extreme temperature and humidity, to ensure the normal operation of the system.

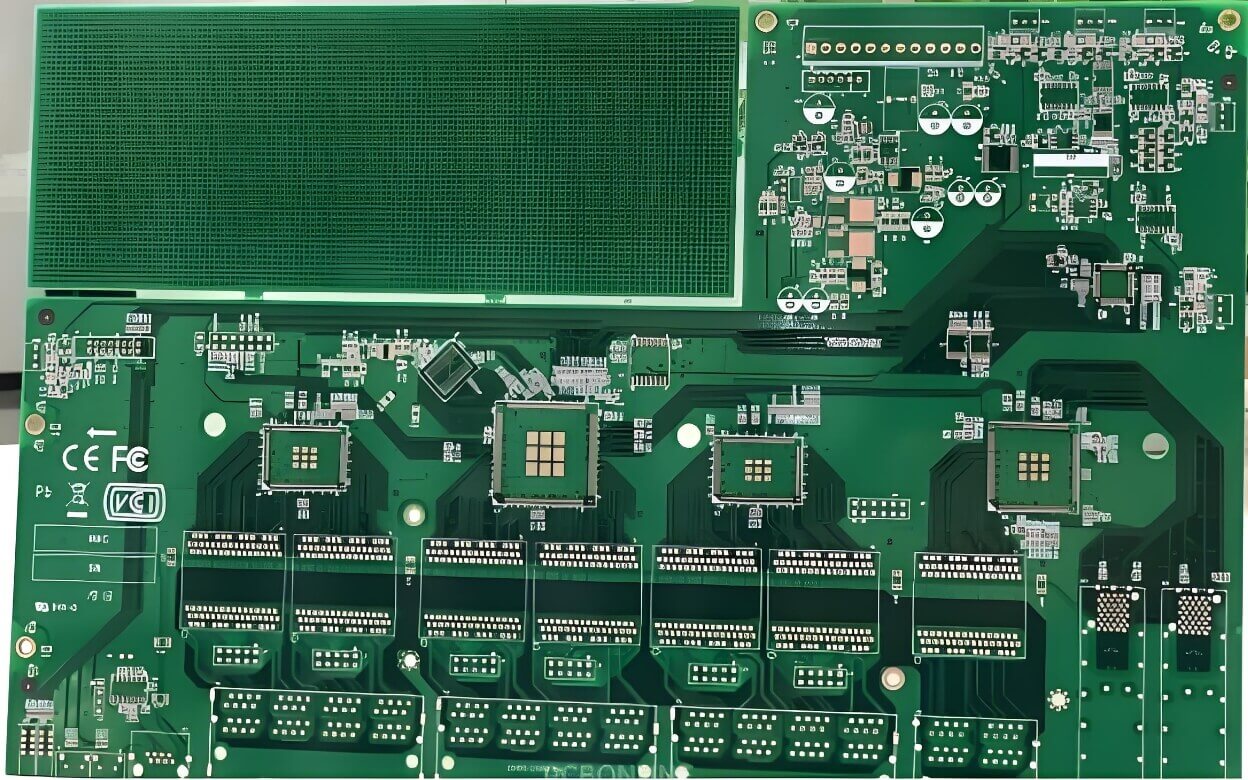

Automotive PCB

3. Future development trend of automotive PCB boards

In the future, automotive PCB boards will become more and more intelligent, convenient and safe. These trends are mainly reflected in the following aspects:

Intelligence

In the future, automotive PCBs will be more connected with other devices in the car and have a higher degree of intelligence. For example, automotive PCB boards can be integrated with internal sensors of the car, and the status of all vehicle equipment can be adjusted through artificial intelligence algorithms to achieve a smoother driving experience.

Convenience

In the future, Automotive PCB boards will use more advanced materials and processes to improve their stability and reliability. This can make vehicle maintenance and repair more convenient and reduce operating costs.

Securitization

The safety of automotive PCB boards has always been an important topic in the field of automotive electronics. In the future, automotive PCB boards will pay more attention to the safety performance of automotive electronics to ensure the safety of the driving process.

In summary, automotive PCB boards are very important electronic components and must have a high degree of safety, reliability and stability. Automotive printed circuit boards can not only improve the performance and efficiency of automotive circuits, but also optimize automotive performance and driving experience. In the future, Automotive printed circuit boards will be more intelligent, convenient and safe, bringing people a more convenient and safer travel experience.