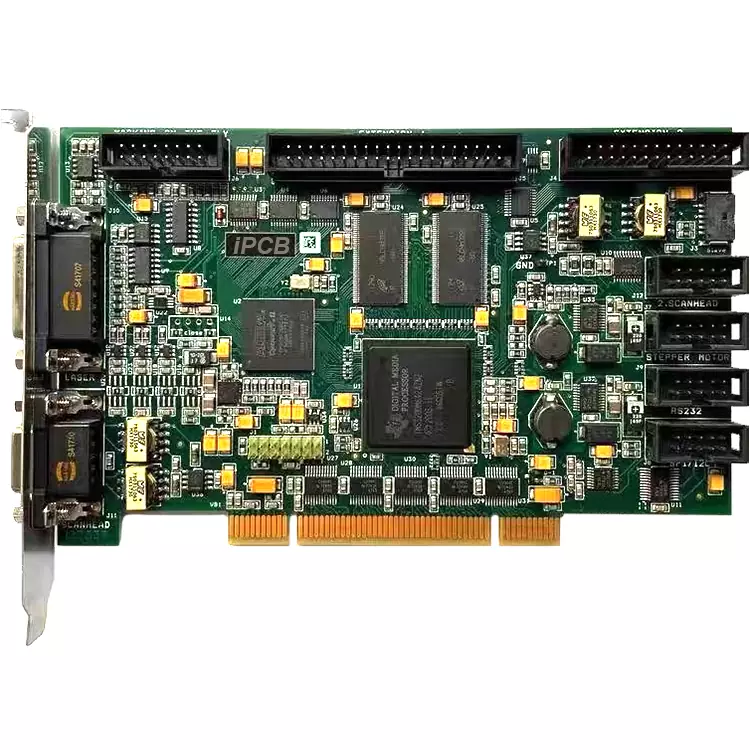

Product Name:Golden Finger PCBA

Material:FR4

Thickness: 1.2mm

Copper thickness: 1OZ

Surface technology:Golden Finger

Solder mask: Blue/Green/

Silk screen: White

Minimum line width/spacing: 3mil

Minimum through-hole: 0.2mm

Application:Computer component

Gold Fingers are long, narrow, thin connection points located at the edge of a circuit board that are used to connect different boards or devices for data, electrical signal and power transmission. They provide physical interfaces for connectors on other boards to make contact with. Gold fingers can be used in devices such as smartphones and smartwatches, and as adapters to transfer network data.

The process of manufacturing gold fingers is a key technology in PCBA (Printed Circuit Board Assembly) processing. The following are its main steps:

1. Substrate treatment: Firstly, the PCB substrate is subjected to surface treatment, such as grinding and cleaning, to ensure the adhesion and flatness of the metal layer.

2. Chemical treatment: the use of chemical gold plating or electroplating process, the metal material is evenly deposited in the gold finger area to form a good conductivity of the metal layer. This step is the key to ensure the conductivity and corrosion resistance of the gold finger.

3. Protective layer treatment: After the metal layer is formed in the gold finger area, a protective layer, such as nickel or alloy, is usually applied to improve the corrosion resistance and service life of the gold finger.

4. Quality inspection: Quality inspection of the gold finger area is carried out to ensure that the conductivity of the metal layer and the stability of the connection meets the requirements. This includes visual inspection, tape testing, and a variety of other methods to ensure the manufacturing quality of the gold finger.

Three common types of gold fingers

Type 1:Uniformly distributed PCB gold fingers are most commonly uniformly distributed, with horizontal or even arrays.pcb pads have the same length, width and space.

Type 2:Uneven PCB Finger PCB pads are the same width but different lengths and sometimes different spaces.For some PCBs,the gold fingers are designed to be shorter than others. The most relevant example of this type of PCB is the PCB for a memory card reader, where the device connected to the long finger must first supply power to the device connected to the shorter finger. The example picture in the first section shows an uneven distribution of the gold fingers.

Type 3:Segmented PCB Gold Fingers PCB pads have different lengths and the gold fingers are segmented.The segmented fingers are of different lengths and some of them are disconnected within the same finger on the same PCB. This type of PCB is suitable for waterproof and ruggedised electronics.

Precautions when designing PCB gold fingers:

Do not arrange pads or screen printing around the gold fingers,as this will cause uneven surfaces in the connection area of the gold fingers,which may prevent smooth insertion, removal and connection of the gold fingers, and in serious cases, may lead to connection failure or damage to the gold fingers.

The gold finger should be placed at the edge of the board so that the gold finger can be precisely aligned with other devices or board connectors and achieve a reliable connection.

PTH holes around the fingers should be avoided as much as possible in the design,as they may make the connection area of the fingers uneven or leave excess metal, thus affecting the insertion, removal and connection of the fingers.

In the design of PCB gold finger,it is recommended to use gold plating process,because the gold plating layer in the connector contact shows higher wear resistance. Whilst immersion gold is cheaper and equally available, its wear resistance is relatively poor.

To ensure that the pcb gold fingers fit perfectly into the slots,each PCB is carefully inspected. This is often done under close scrutiny with the aid of a magnifying glass, and defect detection is also carried out to ensure that subsequent functional tests can be carried out without any problems.

Product Name:Golden Finger PCBA

Material:FR4

Thickness: 1.2mm

Copper thickness: 1OZ

Surface technology:Golden Finger

Solder mask: Blue/Green/

Silk screen: White

Minimum line width/spacing: 3mil

Minimum through-hole: 0.2mm

Application:Computer component

iPCB Corporation provides support for PCB Prototype and Electronic Manufacturing. You can request consultation or quotation for PCB, PCBA and ODM here, please contact email: sales@ipcb.com

We will respond very quickly.