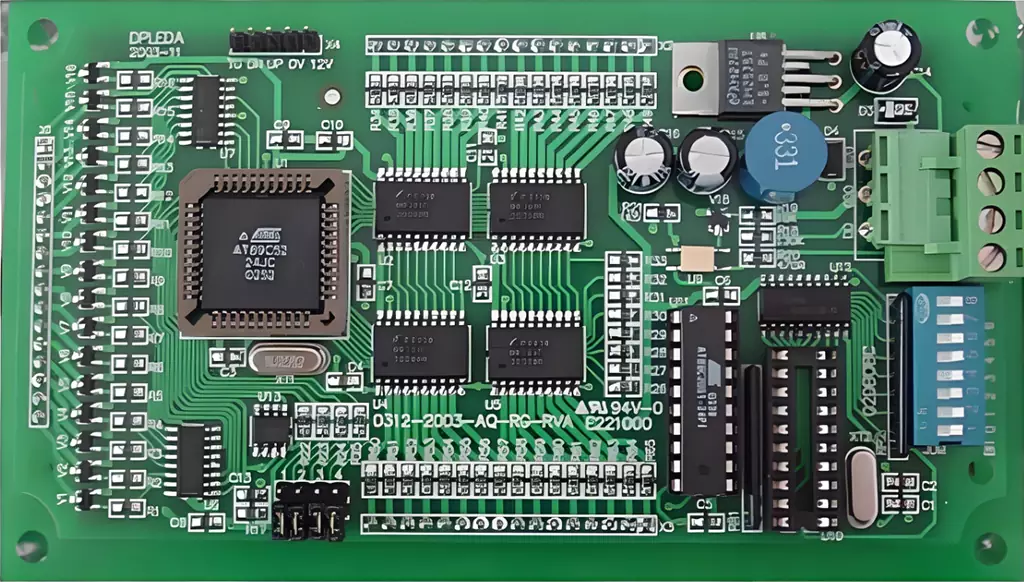

PCBA is the abbreviation of Printed Circuit Board Assembly,which means Printed Circuit Board Assembly.It is based on the PCB, the use of such processes as surface mount technology (SMT) and plug-in technology (DIP) and other means, the resistor. Capacitance. Inductors. Chip and other electronic components assembled to the PCB,and then after welding. Testing and other production processes, and ultimately made of a specific function of the electronic components.

PCBAchip processing is formed by a variety of assembly processes, according to the different types of customer products,the assembly process requirements are also different.Printed circuit board assembly processing process can be roughly divided into SMT chip, DIP plug-in, pcba test. Finished product assembly; these four processes are essential and most important.

1.SMT chip technology process

In the SMT placement process, we purchase electronic components based on the BOM list provided by the customer. Once the production plan has been confirmed, we will start to issue process documents. SMT programming. The specific technical flow of SMT placement includes: solder paste printing, SPI inspection, placement, IPQC, and so on. IPQC first piece inspection. Reflow and AOI inspection. In this process, the printing quality of the solder paste and reflow oven temperature is the need to focus on monitoring the link, because 70% of the SMT patch bad problems stem from these two links in the parameter settings.

2.DIP plug-in workflow

In view of the current trend of precision electronic products,PCBA processing in the relatively small number of plug-in components (except for the type of power supply board),so more manual plug-in operations.DIP plug-in operation process includes: the workstation electronic component allocation.Insertion.IPQC first inspection. Loading jig. Wave soldering.Cut feet.Mending welding.Wash the board and the appearance of the full inspection. In this process,you need to focus on monitoring the direction of the plug-in components and fixtures loaded components whether there is a floating phenomenon.

3.PCBA test process

PCBA test is the most critical PCB assembly processing process quality control links, must be strictly in accordance with the implementation of PCBA test standards, and according to the customer's test programme on the circuit board test points for testing.PCBA test mainly includes four forms: ICT test, FCT test, aging test and reliability test.Aging test and reliability test.

4.Finished product assembly and testing process

Finished product assembly is the PCB assembly board after testing a process of shell assembly. After the assembly is completed,we need to ensure that the finished product surface is free of scratches, and finished product testing.Finally,electrostatic packaging is carried out to complete the whole process.In the process of assembling the finished product,it is necessary to operate in strict accordance with the engineer's product operating instructions and procedures, and any process omissions may increase manufacturing costs.

PCB assembly has a compact size, low energy consumption, high reliability and other characteristics, it has been widely used in the field of electronic products. Next, let's explore the main application areas of PCBA.

Smart home field

Smart home is a home environment automation management system through the integration of a variety of intelligent devices and sensors.In this system,PCBA plays a pivotal role, it is responsible for regulating lighting,indoor temperature,access control security and other types of home equipment.

Industrial Automation

Industrial automation refers to the use of a series of intelligent devices and sensors to promote industrial production processes to achieve automation of the system. In this system,PCBA is responsible for controlling the operation of robots, conveyor belt operation,cylinder action and other types of production equipment.

Security Surveillance

Security monitoring is a system that relies on a variety of cameras and sensors to build a security monitoring network. In this network,PCB assembly plays a key role in controlling security equipment such as cameras that capture images and alarms that sound an alarm.

Medical Diagnostic and Therapeutic Equipment

Medical diagnostic and therapeutic equipment is a variety of devices used for the diagnosis and treatment of disease. In these devices,PCB assembly plays a crucial role, it is responsible for controlling the measurement of sphygmomanometer, the recording of electrocardiograph, the operation of respirator and other medical equipment.

As a core component of modern electronic products,PCBA plays an indispensable role in many key areas by virtue of its unique advantages,promotes the deep integration of science and technology and life,and demonstrates its wide application value and future development potential in the field of electronic products.