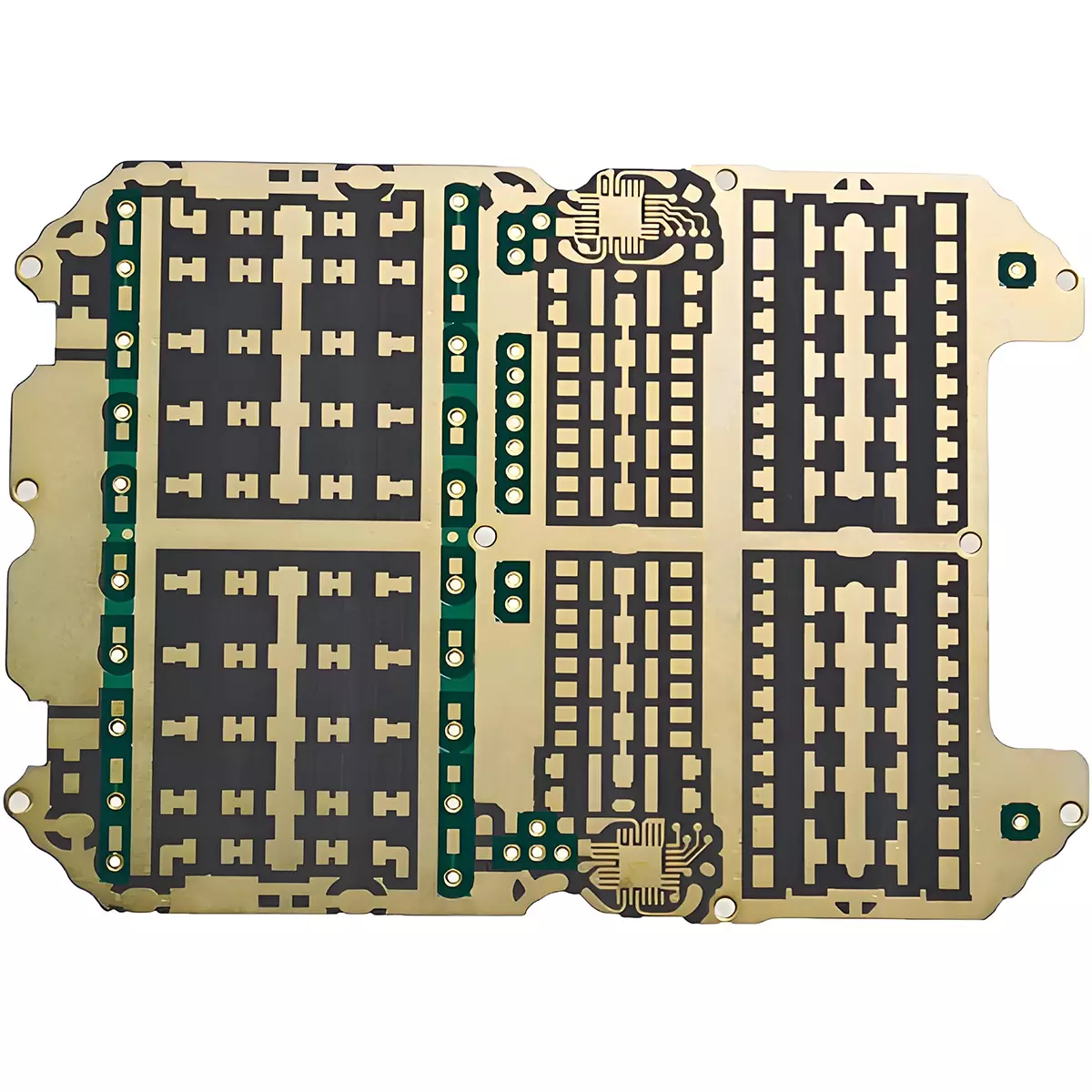

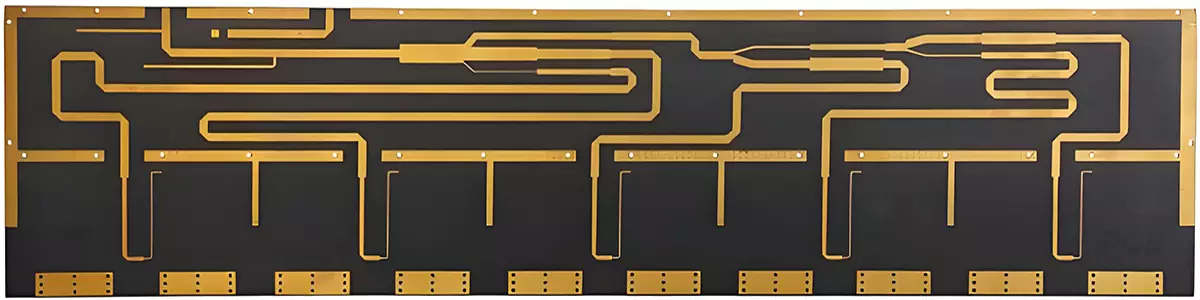

Product Name: PTFE Teflon PCB

Material: polytetrafluoroethylene

Quality standard: IPC 6012

Rogers PCB material Dk: 2.2

Material composition: Teflon,

Layer: 1Layer, 2Layers, multilayer PCB

Thickness: 0.1mm - 12mm

Copper thickness: 1oz

Surface technology: Gold

Application: RF, Microwave, Radar

Teflon PCB, also known as polytetrafluoroethylene (PTFE) PCB board, is a special type of printed circuit board widely used in the field of high-performance electronics. It has been widely used in multiple fields due to its excellent characteristics, especially in communication equipment, RF applications, and high-temperature environments.

Teflon PCB is a widely used high-performance RF circuit board material in many electronic devices, characterized by high temperature resistance, chemical stability, electrical insulation, and moisture resistance.

Advantages of PTFE PCB board

High temperature resistance: Teflon PCB can operate for a long time at temperatures up to 280 ℃ without melting, deforming, or degrading due to high temperatures.

Chemical stability: As Teflon PCB itself is an inert substance, the reinforcing agents and fillers added to the circuit board material are also chemically stable materials, which can withstand the corrosion of most chemical substances such as acids, alkalis, oxidants, and reducing agents, and will not be corroded by them. It can operate stably for a long time.

Electrical Insulation: Teflon PCB has high electrical insulation strength, low dielectric constant, and low dielectric loss, which can effectively prevent electrical breakdown, ensure clear and stable signals, and improve circuit reliability.

Moisture resistance: Teflon PCB is a non absorbent material that can effectively prevent the infiltration of moisture and water, protect the components and circuits in the circuit board from being corroded by humid environments, and thus extend the service life of the circuit board.

Disadvantages of PTFE PCB board

Cold flowability: Teflon materials have a certain degree of cold flowability, which may cause slight changes in the shape and size of the material in certain applications.

Processing difficulty: Due to the special properties of Teflon PCB, such as high lubricity and non adhesiveness, its processing difficulty is relatively high. During the PCB wiring and drilling process, issues such as air gouging or tearing are prone to occur.

High cost: Compared to traditional FR-4 PCB, the cost of Teflon PCB is significantly higher. This is mainly due to its special PTFE PCB production process and material costs.

PTFE PCB board

Teflon PCB is widely used in aerospace, aviation, satellite communication, navigation, aerospace, radar, electronic countermeasures, 3G, 4G, 5G communication, Beidou satellite system and other fields due to its unique performance. Especially the F4BM series Teflon PCB substrate has a high price advantage and has become the preferred choice for many industries.

During the manufacturing process of Teflon PCB, special processing methods are required due to their material properties. For example, PTFE surface is prepared using plasma gas recovery or sodium etchant, and a solder mask layer is used within 12 hours after the material is etched. During the drilling process, high chip load technology is used to eliminate PTFE tailings and fine threads.

The manufacturing of Teflon PCB also involves some special processes, such as metalized edge wrapping and mixed pressing, controlling the tolerance of metalized short grooves and crimping hole diameters within+-0.05mm, all to ensure the high precision and performance of PCB board. These processes can improve the performance and durability of RF circuit board.

Product Name: PTFE Teflon PCB

Material: polytetrafluoroethylene

Quality standard: IPC 6012

Rogers PCB material Dk: 2.2

Material composition: Teflon,

Layer: 1Layer, 2Layers, multilayer PCB

Thickness: 0.1mm - 12mm

Copper thickness: 1oz

Surface technology: Gold

Application: RF, Microwave, Radar

iPCB Corporation provides support for PCB Prototype and Electronic Manufacturing. You can request consultation or quotation for PCB, PCBA and ODM here, please contact email: sales@ipcb.com

We will respond very quickly.