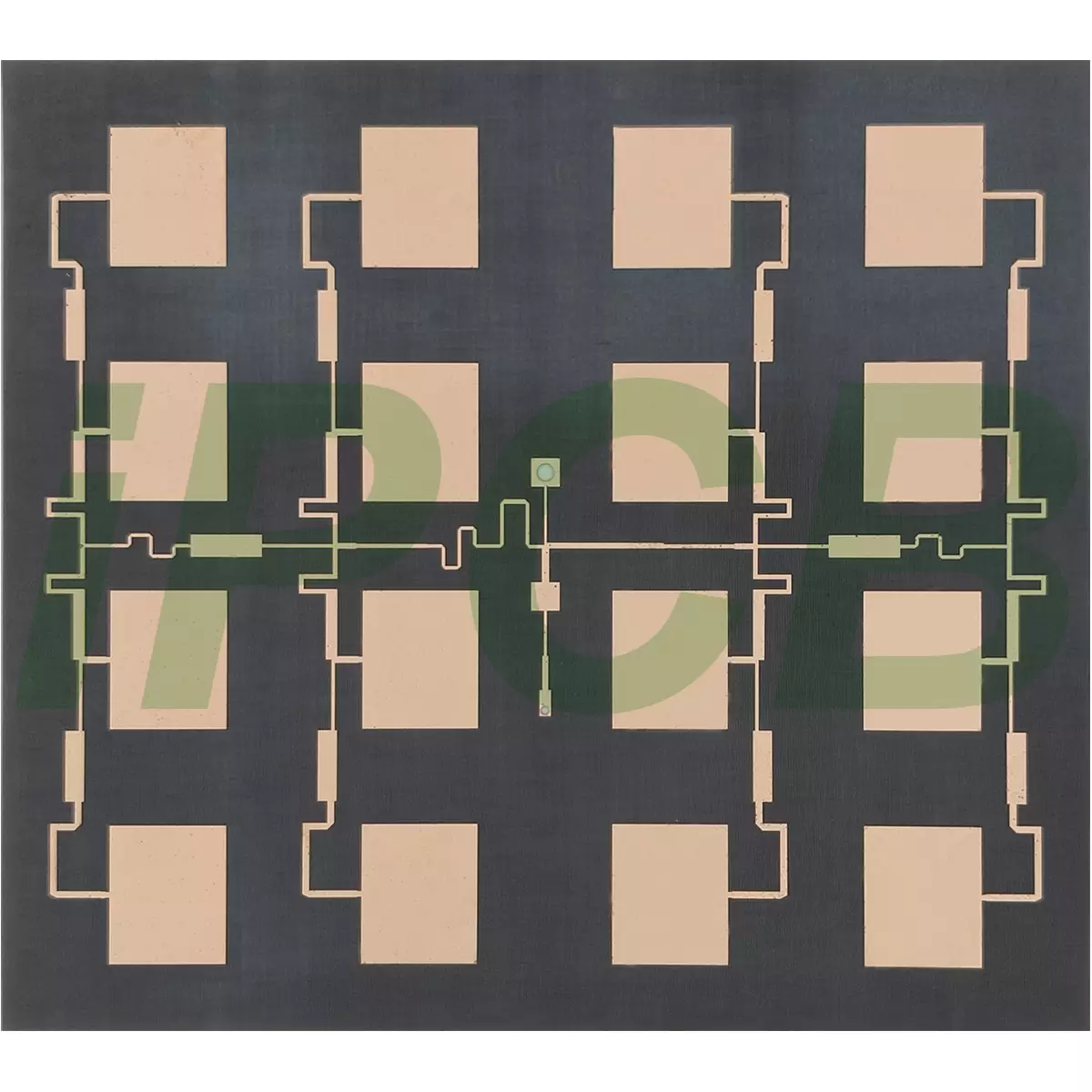

Product Name: Rogers 5880 PCB

Material: rogers PCB material

Quality standard: IPC 6012

Rogers 5880 Dk: 2.2

Rogers 5880 Df: 0.0009

Material composition: PTFE+Fiberglass

Layer: 1L - multilayer PCB

Thickness: 20mil - 60mil

Copper thickness: 1oz

Surface technology: Silver, Gold,

Application: High-frequency Circuit Board

The Rogers RT/duroid 5880 PCB is made of polytetrafluoroethylene glass fiber reinforced material. These microfibers are randomly distributed within the material, providing excellent strength enhancement effects for circuit design and production processes.

Rogers 5880 PCB have the lowest dielectric constant among similar products, and their extremely low dielectric loss characteristics make them particularly suitable for high-frequency, wideband applications that require minimal dispersion and loss. In addition, the extremely low moisture absorption rate of the Rogers 5880 circuit board makes it an ideal choice for applications in high-humidity environments.

The Rogers 5880 PCB is easy to cut into the desired shape and can resist corrosion from various solutions and reagents used in processes such as etching and through-hole plating. The R Rogers 5880 PCB board not only has the lowest dielectric loss and low moisture absorption rate among polytetrafluoroethylene materials but also has the characteristics of isotropy and minimal electrical performance variation with frequency.

In order to meet the increasingly stringent requirements of high-frequency circuit design for board, Rogers 5880 is made of polytetrafluoroethylene glass fiber reinforced material, with randomly distributed internal microfibers, ensuring high strength requirements for board during circuit application and production processes.

According to the 10GHz IPC-TM 2.5.5.5 standard measurement, the dielectric constant of Rogers 5880 PCB is 2.20 ± 0.02. At the same time, measured under the same standard, the dielectric loss of 5880 PCB board is only 0.0009. This extremely low dielectric loss characteristic makes it very suitable for high-frequency and wideband applications that require minimizing dispersion and loss. The highest supported frequency can reach Ku band or even higher.

The Rogers 5880 PCB has an extremely low moisture absorption rate of only 0.02%, making it an ideal choice for applications in high humidity environments.

The Rogers 5880 PCB can perfectly adapt to the shape requirements of various cavity structures for PCB printed circuit board in high-frequency applications. As a high-frequency circuit board, the RT5880 PCB supports a thickness range of 8-70um for electrodeposited copper, and can resist the erosion of various acidic and alkaline reagents used during processing, as well as the tests of various high and low temperature processing procedures.

Rogers 5880 PCB also has the lowest dielectric loss, low moisture absorption rate, and excellent isotropy among polytetrafluoroethylene materials, and its electrical performance changes very little with frequency. This enables RT/duroid 5880 to demonstrate outstanding performance in commercial aviation telephone circuits, microstrip and strip line circuits, millimeter wave applications, military radar systems, missile guidance systems, and point-to-point digital radio antennas.

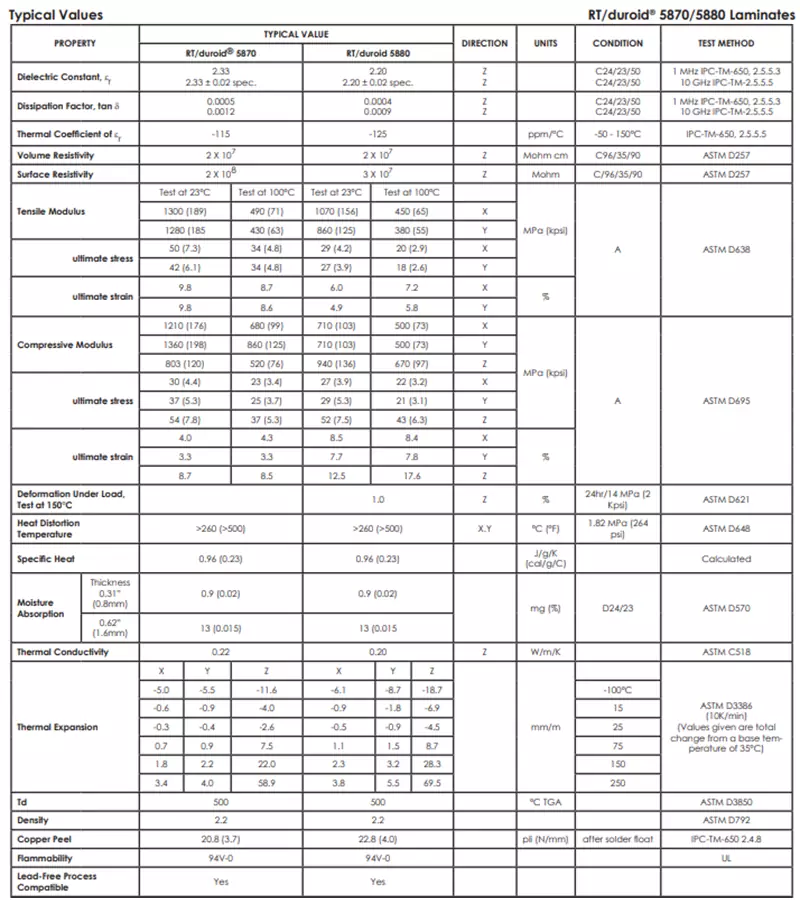

Rogers 5880 and Rogers 5870 DataSheet

The difference between Rogers 5880 and Rogers 5870

Rogers RT/duroid 5880 and RT/duroid 5870 are both high-frequency circuit board made of polytetrafluoroethylene (PTFE) composite material and reinforced with glass microfibers. What is the difference between Rogers 5880 and Rogers 5870?

1. Dielectric constant (Dk): Rogers 5880 has a lower dielectric constant, which makes it have lower signal delay and better performance in high-frequency applications. According to the collected results, the dielectric constant of Rogers 5880 is 2.20 ± 0.02, while the dielectric constant of Rogers 5870 is 2.33 ± 0.02.

2. Dielectric loss (Df): The dielectric loss factor of Rogers 5880 is lower, indicating that it has less loss in high-frequency signal transmission. The dielectric loss factor of Rogers 5880 is 0.0009, while the dielectric loss factor of Rogers 5870 is 0.0012.

3. Coefficient of thermal expansion (CTE): Rogers 5880 and Rogers 5870 have different coefficients of thermal expansion in different axes, which can affect the dimensional stability of the circuit board under temperature changes.

4. Water absorption rate: Both Rogers 5880 and Rogers 5870 have very low water absorption rates, but the specific values differ, which affects the performance of the material in humid environments.

When choosing Rogers 5880 and Rogers 5870, high-frequency circuit board designers need to decide which material to use based on specific application requirements, such as signal frequency, transmission rate, cost budget, and space limitations. Both Rogers 5880 PCB and Rogers 5870 have their unique advantages and application scenarios, and choosing the right one can significantly improve the performance of the final product.

Product Name: Rogers 5880 PCB

Material: rogers PCB material

Quality standard: IPC 6012

Rogers 5880 Dk: 2.2

Rogers 5880 Df: 0.0009

Material composition: PTFE+Fiberglass

Layer: 1L - multilayer PCB

Thickness: 20mil - 60mil

Copper thickness: 1oz

Surface technology: Silver, Gold,

Application: High-frequency Circuit Board

iPCB Corporation provides support for PCB Prototype and Electronic Manufacturing. You can request consultation or quotation for PCB, PCBA and ODM here, please contact email: sales@ipcb.com

We will respond very quickly.